BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

The ALTRA 280 was engineered to solve a challenge that's persisted for years: reliably and affordably producing large, complex parts in both engineering-grade and high-performance polymers.

How Miniaturisation is Reshaping Product Development

Products are shrinking, yet their functionality and complexity are growing exponentially. This shift is rewriting the rules of design, engineering, and manufacturing.

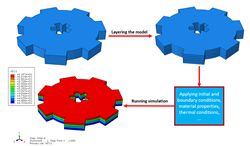

Basics of 3D Printing Simulation: Answering Key Questions

This article provides a comprehensive overview of additive manufacturing simulation, which involves virtually testing and optimizing the 3D printing process.

Indian Aircraft Manufacturing Company Raphe mPhibr Revolutionizes Unmanned Aerial Vehicle Innovation with Dassault Systèmes' 3DEXPERIENCE Platform

Dassault Systèmes' 3DEXPERIENCE platform helped Raphe mPhibr reduce prototype development time from years to three months. The 3DEXPERIENCE platform integrates design, simulation and collaboration, supporting in-house design and manufacturing

Rewriting the Rules of Scalable Manufacturing

The project, which fused AM-driven computational design with production-grade investment casting, successfully scaled an intricately engineered part from tens to thousands per day - all without compromising performance, cost-efficiency, or sustainability.

DFAM: WHY PURPOSEFUL GEOMETRY MUST REPLACE PASSIVE OPTIMISATION

Rather than embracing the full potential of AM, many engineers merely adapt existing designs or lean heavily on software-driven outputs, confusing automation with optimisation.

Barriers to investing in CNC automation in 2025 - Transforming CNC automation obstacles into pathways for growth

Here Hakan Aydogdu, CEO at Tezmaksan Robot Technologies delves into these critical obstacles and reveals how innovative technologies and forward-thinking strategies are breaking down barriers, paving the way for a transformative shift in manufacturing.

3D Printing Revolution: How Localized Manufacturing Is Reshaping Global Trade

In the realm of advanced manufacturing, robotic large-format additive manufacturing (LFAM) is rapidly emerging as a strategic tool for businesses seeking to bypass traditional trade constraints and build more resilient operations.

Renishaw helps Tronosjet Manufacturing achieve FAA certification

Renishaw supplied multiple laser powder bed fusion (LPBF) AM systems, which Tronosjet uses to produce various aircraft components.

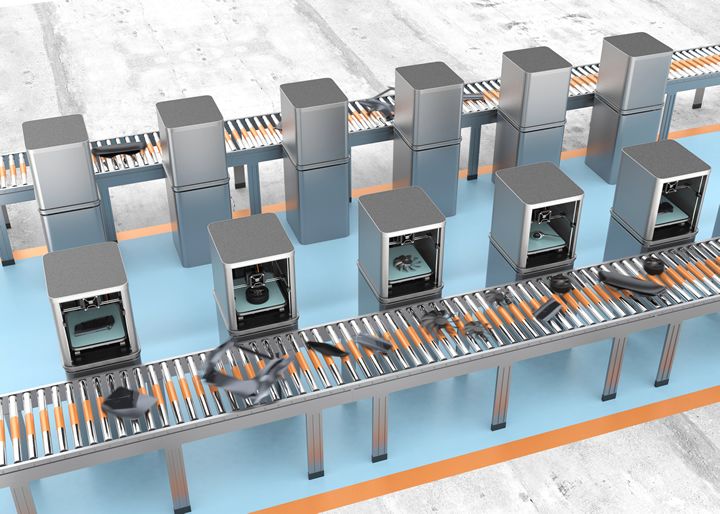

How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

Securing Intellectual Property in 3D Printing: A New Era of Protection

By decentralizing manufacturing and leveraging external service bureaus, companies can deliver products faster and tailor offerings. However, due to both its quick, cost-effective, and precise manufacturing process, 3D printing is a fine target for counterfeiting.

The Evolution of Mass Custom Manufacturing: Why the Industry Needs a High-Velocity Shift

HVMC is not just faster production but a fundamental reimagining of how custom manufacturing operates. By standardizing and automating processes without sacrificing the ability to tailor products to specific needs, HVMC has the potential to transform the landscape.

The Hidden Cost of Convenience - Why 3D Printing Shouldn't be Left only to an Algorithm

At first glance, the idea of an entirely self-service 3D printing experience is appealing. Who wouldn't want an instant quote? Who wouldn't prefer the simplicity of a few clicks over a back-and-forth exchange with a human?

AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

WHY PHOTO-CHEMICAL ETCHING IS BECOMING CRITICAL FOR HIGH-PRECISION INDUSTRIES

As industries continue to innovate, the demand for high-precision components grows exponentially. Medical devices require intricate surgical instruments and implants that must meet stringent safety standards.

Records 1 to 15 of 783

Additive & 3D Printing - Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)