When Clean is the Key to Precision

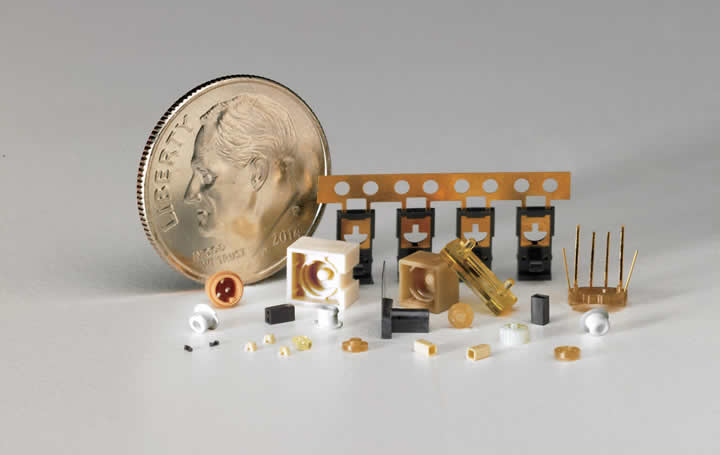

Micro molded parts are often invisible to the naked eye, measured in millimeters or fractions of millimeters, with features that can be smaller than a human hair. In this context, a single dust particle can disrupt form, fit, or function.

Investing in the UK's injection moulding sector - The case for all-electric machines and robotic integration

Traditionally, our manufacturers have relied on hydraulic-powered injection moulding machines in their operations. However, the industry is now at a crossroads, faced with the imperative to embrace technological advancements for sustainability and cost-effectiveness.

Using Advanced Cooling Techniques to Reduce Cycle Times and Improve Quality in Injection Molding

If parts do not cool down enough or cooling happens unevenly, they can shrink or warp, requiring time-consuming rework processes. Fortunately, numerous ways exist to accelerate cooling time while ensuring it happens effectively.

The Future of Injection Molding Relies on Automation

While demand for injection molding products grows, manufacturers are grappling with persistent challenges, particularly staffing and output.

Sustainability and Plastic Injection Molding in the Automotive Industry

With the ability to use various materials to produce automotive components, car manufacturers will turn to the plastic injection molding industry as the solution.

3D Printing - an Alternative to Injection Moulding?

3D printing technologies have been refined to such an extent that they are truly viable production technologies. Now the conversation among manufacturers is around the most judicious use of 3D printing for production.

Three Ways Autonomous Machine Vision (AMV) Benefits Plastic Injection Moulding

Plastic injection moulding is a difficult application for machine vision. The highly reflective surface of plastics is hard to illuminate, and the fact that the same production line can create items of different colours and shapes is problematic for traditional solutions.

Calculating Injection Molded Plastic Part Shrinkage

When designing any part for injection molding, it is important to consider the shrinkage and contraction rate of the material and the associated geometry of the component. Plastic shrinkage is the dimensional change that occurs in a molded part as it cools after injection.

PRECISION MOLDING & THE INTERNET OF THINGS

While most analysis of the IoT is in respect of its positive influence on manufacturing processes, the growth in the IoT also opens up huge possibilities for micro molding as there is burgeoning demand for a variety of new and innovative micro devices.

In-house Packaging Operations Propels Growth for Tropical Trade & Industries N.V.

New blow-molding equipment and custom bottle designs boost sales by 24 percent in a year for Caribbean syrup and essence manufacturer.

Injection-Molded Plastic Allows More Creativity than Ever Before

Not being limited to metal (or a few standard plastics) opens up a much wider range of design options for engineering and design teams. They can think in more creative ways about complex geometry, performance in harsh environments, shielding considerations etc.

Extending the Life and Improving the Performance of Plastic Injection Molds

Coating mold components like ejector guide elements, cores, lifts and cavities increases the lifespan of molds while reducing maintenance and running costs.

How Colorants Affect Plastic Characteristics

Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect the behavioral properties of the plastic.

Injection Molding Design & Process Optimization

This approach is superior to standard molding procedures because of the high level of scientific control utilized through upfront Design of Experiments (DoE), flow analysis, process monitoring, and quality control that can quickly detect and correct any process variations.

Hand Loads: Cost Effective Solutions for Complex Plastic Parts

It's important to note that hand loads require extra labor for installation and removal. While this may skew the cost/benefit analysis, it may also be the only way to meet the customers needs.

Records 1 to 15 of 18

Featured Product

Datanomix Production Monitoring

Datanomix Production Monitoring delivers instant visibility into your shop floor performance. Through real-time alerts, simple machine connectivity, and our kick-ass coaching, you'll catch inefficiencies early, align your team with meaningful metrics, and respond faster to issues before they escalate. The software adapts without operator input and works out of the box with purpose-built Tracks (Efficiency, Delivery, Tooling, and more). Production Monitoring arms you with the data to make more, waste less, and lead with confidence. And while real-time visibility keeps you sharp in the moment, historical insights ensure you're learning from the past to drive ongoing continuous improvement.

Manufacturing and Automation - Featured Company

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

.jpg)