Supply Chain - Articles, Stories & Interviews

Unlocking the Benefits of a Data-Driven Manufacturing Supply Chain

A data-driven supply chain isn’t just about tracking shipments. It’s about turning a mountain of raw data: sales figures, inventory levels, supplier performance, even weather patterns, into actionable insights. It allows supply chains to anticipate problems before they o

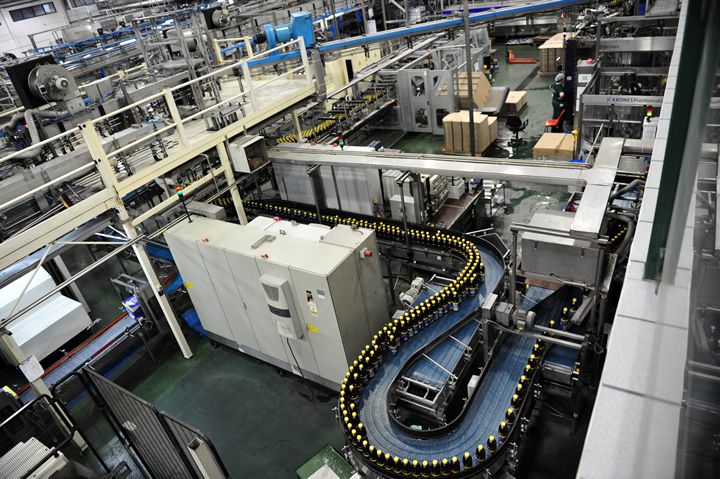

Maximizing Operation Efficiency through Manufacturing Processes

Cross-functional collaboration isn’t just helpful, it’s the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations and supply chain aren’t aligned from day one, you’re setting yourself up for late-stage su

Talking PACK EXPO Las Vegas with Encoder Products Company (EPC)

We’re featuring live demos of our newest encoders, including the LP1 Accu-LaserPro™ — a slip-free, high-accuracy laser encoder designed for packaging lines. Visitors will see how EPC encoders reduce downtime, simplify integration, and deliver long-lasting performance.

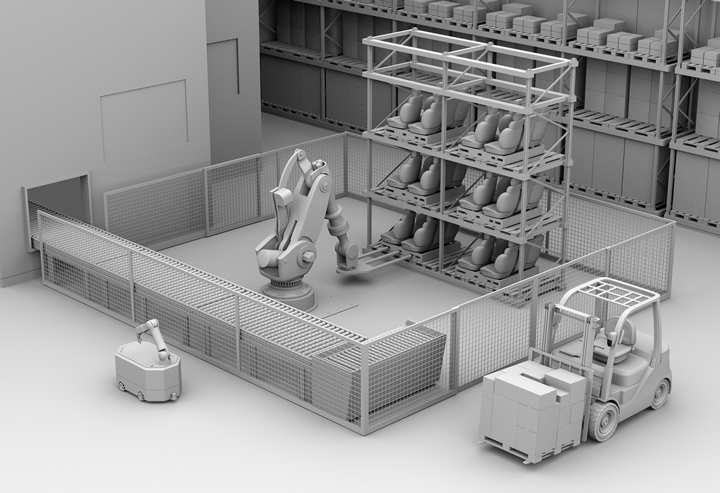

Driving Supply Chain Innovation Through AI and Process Optimization

AI and data analytics are game changers for the manufacturing industry’s demand and shop floor agility. My team is currently developing an AI model that identifies irregular demand patterns and updates itself.

PACK EXPO 2025 Product Preview

PACK EXPO 2025 takes place September 29th - October 1st in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Talking PACK EXPO Las Vegas with NORD DRIVESYSTEMS

We’re bringing the full package. Our booth will showcase complete drive solutions, including gear units, motors, and VFDs, all designed for high-volume, high-throughput environments. A highlight will be the launch of a new hygienic, caustic washdown solution.

Transportation & Logistics Company Cuts Costs and Improves Asset Tracking with HiveMQ

As the shipping and logistics company scaled and especially during their peak season between Black Friday and Christmas, the number of devices, connections, and topics being created overwhelmed the broker, causing a lot of headaches.

Supply Chain - Featured Stories

Top 5 AI-Powered Capabilities to Look for in a WMS Vendor

Success depends on how deeply and thoughtfully those capabilities are embedded into the system. As you evaluate vendors, look beyond the buzzwords and focus on practical AI tools that deliver faster deployment, smarter execution, and long-term flexibility.

Adaptive Ventilation Is Creating Healthier, More Efficient Manufacturing Spaces

.jpg)

As manufacturing leaders assess how to make their facilities more energy-efficient while promoting better working conditions to support employee health, many become interested in adaptive ventilation solutions.

Prepare for the Biggest and Most Comprehensive PACK EXPO Las Vegas

PACK EXPO Las Vegas is this year’s largest gathering of packaging and processing professionals, offering attendees unique opportunities to uncover key technology solutions and make the connections that drive businesses forward.

Supply Chain - News Headlines

SinceVision Joins Japan Industrial Imaging Association to Strengthen Global Machine Vision Presence

SinceVision, a manufacturer of industrial vision sensors and high-speed cameras, has become a member of the Japan Industrial Imaging Association (JIIA). The move positions SinceVision among Japan's top industrial imaging firms and underscores its push to align with global standards in machine vision and smart manufacturing.

Cleo Launches Invoice Payment and Financing Solution to Help Suppliers Get Paid Faster

Cleo InvoicePay improves cash flow for suppliers, giving them access to immediate capital without impacting customer relationships or existing contracts

DigiKey to Feature New Products and Top Suppliers at Maker Faire Rome 2025

Live demos and in-booth giveaways planned for maker event

Supply Chain - Featured Product

Line Vac™ Family

Line Vac™ Family

A fast, low cost way to convey plastic pellets, scrap trim, textiles, bulk solids, food products, chips, paper, pills/tablets, small parts, shavings, sawdust and granules.

EXAIR's compressed air operated Line Vac connects to standard hose or tube to create a powerful in-line conveyor. The compact design features large throat diameters for maximum throughput capability. Eleven sizes in aluminum and ten in stainless steel are suited to a wide variety of transfer applications.

Line Vac conveyors are ideal for moving large volumes of material over long distances. A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other, with instantaneous response. The material flow rate is easily controlled with a pressure regulator. No moving parts or electricity assures maintenance free operation. https://exair.co/184_564

See our Line Vac Promotion running now. http://www.exair.com/184/lvpromo.htm

Supply Chain - Featured Company

EXAIR

EXAIR intelligent compressed air® products solve problems in industrial plants while reducing compressed air consumption and increasing safety for personnel. We have the largest variety of sizes, materials and performance characteristics in order to provide the best solution for your processes and problems.

Our products are commonly used to conserve air, cool processes or parts, convey material, clean surfaces or coat surfaces. EXAIR's 15 extensive product lines include air knives, air wipes, air nozzles and jets, atomizing nozzles, static eliminators, cold gun air coolant systems, air amplifiers, safety air guns, air operated conveyors, industrial housekeeping products, vortex tubes and spot cooling products, cabinet cooler systems, vacuum generators, compressed air optimization products, and associated accessories.

Products meet OSHA standards and are CE and RoHS compliant. Five-year warranty on compressed air products and one-year warranty on accessories and electrically powered products.

.jpg)