What's Your Factory's Lean Maturity Score?

Many factories run 5S events, collect defect data, or deploy quality management systems - yet still face recurring bottlenecks, waste, and variation. Why? Because tools alone don't make a Lean enterprise - culture does.

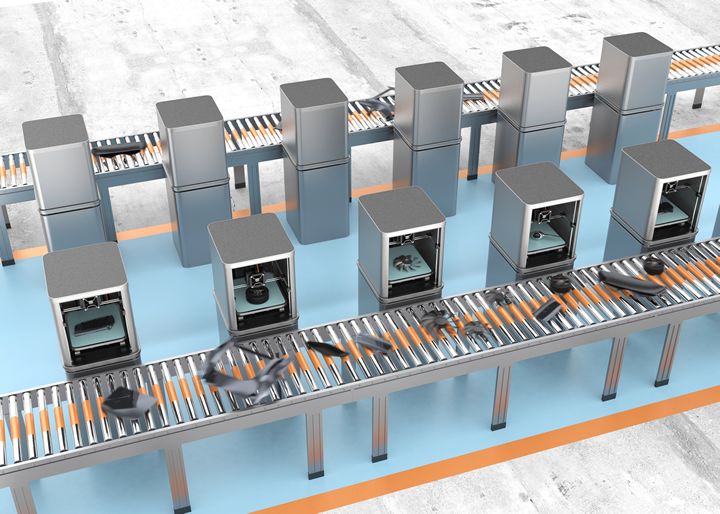

AI + Lean: How U.S. Manufacturers Can Blend Tradition with Technology

Lean manufacturing remains the timeless backbone of operational excellence. It provides the structure, culture, and discipline that no technology can replace. But in an era of vast data and real-time demands, AI acts as a powerful multiplier.

6 Steps to Build a Continuous Improvement Culture in American SMEs

This blog outlines 5 practical, proven steps that leaders in American SMEs can use to build a culture where improvement isn't a project-it's just how work gets done.

The Next Evolution of Configure-to-Order in Manufacturing

Static bills of materials, disconnected tools, and manual workflows limit scalability. They slow timelines, erode margins, and make it harder to manage increasing product complexity across the lifecycle.

Unlocking the Next Era of Supply Chain Maturity: How AI and Machine Learning Drive Transformation

While foundational theories like Lean Supply Chain Management, Agile Supply Chain, and the Theory of Constraints have long helped businesses streamline operations, AI & ML are emerging as catalysts that can take supply chain maturity to the next level.

Lean is the Future of Manufacturing

Reducing wait times and eliminating extraneous handling and labor through lean improves your bottom line. The capital saved can then be reinvested in new and better products and processes to further improve the customer experience, which in turn fuels business growth.

Lean Manufacturing and Low-Code: How to Eliminate Waste and Increase Efficiency

Identifying tools and techniques to eliminate Gray Work is the main objective of implementing lean manufacturing processes. The benefits for companies that successfully implement lean processes extend beyond just eliminating waste.

The 8 Wastes of Lean Manufacturing

The lean manufacturing methodology chiefly revolves around minimizing production times and raising efficiency by eliminating waste. In this post, we go through the 8 principal wastes in lean manufacturing and see how manufacturing software can help to address them.

Lean manufacturing losing pulling power - New approach required to ensure a steady supply

An increase in the price of raw materials, coupled with increasing uncertainty in manufacturing supply chains, has led many to rethink their stock management.

How to Go Lean With Your Assembly Line Layout

Every operation has different goals and resources, so what lean looks like will vary. Still, there are some general concepts you can follow to create a lean assembly line.

Lean Manufacturing Now Focuses on Pricing During Pandemic

For more than a quarter century Lean Manufacturing has been focused on plant floor process improvement. While these efforts have eliminated waste in the operation, rarely have pricing elements been considered part of a value stream mapping (VSM).

5 Continuous Improvement Tools to Help Streamline Manufacturing Processes

Continuous improvement tools can enhance and streamline your lean manufacturing process. Leveraging the right tool at the right time can increase your profitability, reduce process errors and improve productivity.

Small Manufacturers Finally Receive Respect: Affordable Access to Competitive Pricing

There is now an affordable pricing optimization solution for small and midsized manufacturers; this transformation will allow even the smallest manufacturer to utilize lean principles in the pricing process immediately.

Top Article of 2019 - The Power of Lean Manufacturing

As a systematic way to increase efficiency and better please customers, lean principles run counter to traditional mass-production practices. Yet, they allow small and medium businesses to consistently increase quality while decreasing costs.

Lean Manufacturing Automation 2019: Digital Visual Management Platform Automates Lean, Six Sigma, Agile Practices

Boards with consolidated key performance indicators (KPIs) ensure that duplicated information is eliminated; it eliminates waste and supports Lean Manufacturing principles.

Records 1 to 15 of 18

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.

.jpg)

.jpg)