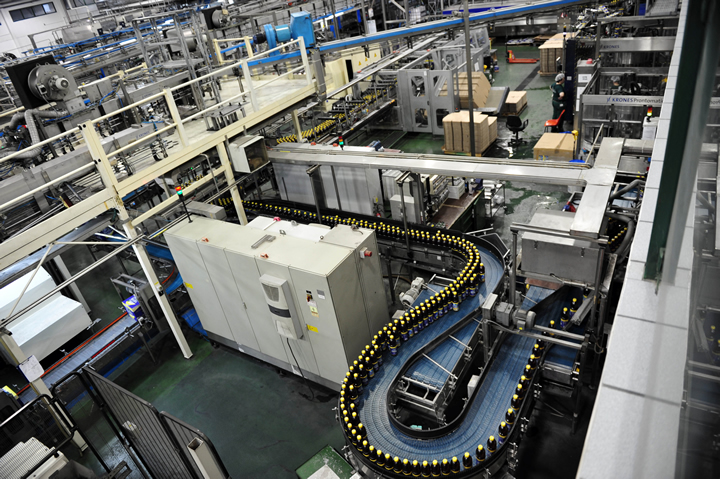

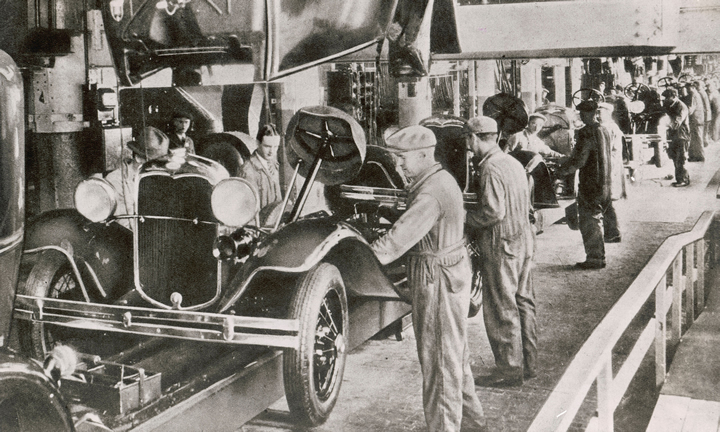

How Real-Time Manufacturing Operations Drive Competitive Advantage in Volatile Markets

Manufacturing executives confronting today's operational challenges recognize a fundamental truth: traditional execution systems designed for stable markets have become organizational liabilities.

Outlook for manufacturing to 2028

Technological advancements, consumer demand and global markets have always had the power to change the manufacturing industry, and in the coming years it is inevitable that we will see some big changes.

Lean Manufacturing and Low-Code: How to Eliminate Waste and Increase Efficiency

Identifying tools and techniques to eliminate Gray Work is the main objective of implementing lean manufacturing processes. The benefits for companies that successfully implement lean processes extend beyond just eliminating waste.

Understanding and Mitigating Insider Threats in Operational Technology (OT) Systems

One of the biggest risks to operational technology (OT) security is not a zero-day rootkit, but the people onsite day in and day out.

Records 1 to 4 of 4

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Manufacturing and Automation - Featured Company

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today.

How can the FAULHABER MICROMO team help you deliver your next innovation to market first?

Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at www.micromo.com.