The Evolution of Mass Custom Manufacturing: Why the Industry Needs a High-Velocity Shift

HVMC is not just faster production but a fundamental reimagining of how custom manufacturing operates. By standardizing and automating processes without sacrificing the ability to tailor products to specific needs, HVMC has the potential to transform the landscape.

The Hidden Cost of Convenience - Why 3D Printing Shouldn't be Left only to an Algorithm

At first glance, the idea of an entirely self-service 3D printing experience is appealing. Who wouldn't want an instant quote? Who wouldn't prefer the simplicity of a few clicks over a back-and-forth exchange with a human?

Launching of a 3D Printing Company

In this interview, the co-founders of 3D People Sasha Bruml and Felix Manley, talk about what motivated them to launch the company in 2017 and how they stay motivated to keep delivering and continue adding value for their customers.

RAPID + TCT 2022 Promises "Next Level" Innovation in Additive Manufacturing

This May, more than 10,000 additive manufacturing (AM) professionals will return to Detroit for RAPID + TCT, North America's largest and most influential AM event.

3D Printing Platform Could Shape the Future of Spare Part Production

The use of 3D printing technology to enable the fast availability of spare parts - when needed, where needed, in exactly the right quantity needed, is now, thanks to German company Replique, becoming a reality.

Evolution of the Need for Expeditionary Manufacturing

There is a demand signal to produce a machine capable of Metal printing on the front lines. Phillips has developed a Hybrid technology that adds a Wire fed Direct Energy Deposition head to a Haas machine.

3D PRINTING & THE SUPPLY CHAIN

Today a growing number of robust plastic and metal 3D printing technologies exist with the accuracy and repeatability required for use in end-use part and component production, and the palette of materials is extensive.

3D Printing Assistive Devices for People with Disabilities

One of A3D's engineers met with the individual to best understand their specific situation and designed a handle that could attach to standard milk and juice cartons. A3D then used Simplify3D to print the handle.

Multi Property Optimization for Injection Moulding to Maintain Safety and Reduce Manufacturing Costs

The company's collaboration with Additive Flow for a particularly challenging project involving a metal and polymer over moulded component, ensured yet another successful outcome for Comeragh that will open up further opportunities in the future.

Micro Molding - The Need for Collaboration and DfM

This article examines the ways in which companies looking to achieve significant product miniaturization need to approach their product development process, and how they need to adapt their thinking when embracing micro molding.

ManufacturingTomorrow - Special Tradeshow Coverage

RAPID + TCT

RAPID + TCT 2019 takes place in Detroit, MI May 20th - 23rd. This ManufacturingTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

GE Awarded $9 Million from Office of Naval Research to develop framework enabling the rapid qualification and certification of 3D Printed Parts

3D printing could replace legacy manufacturing processes no longer in use to produce decades-old replacement parts

Tulip Launches the Industry's First Digital Manufacturing Quick-Start Kit

Factory Kit leverages Tulip's award-winning Manufacturing App Platform, which brings the power of Industrial IoT and advanced analytics to the front-line engineer and the associate on the shop floor.

ManufacturingTomorrow - Special Tradeshow Coverage

RAPID + TCT 2018

RAPID + TCT 2018 took place in Fort Wort, TX April 24th - 26th. This ManufacturingTomorrow.com Special Tradeshow report aims to bring you news, articles and products from this years event.

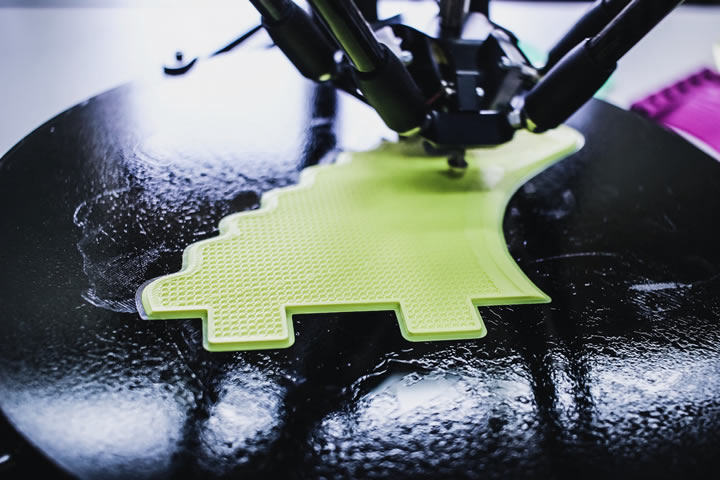

buildPl8 Manufacturing Launches Cloud Based 3d Printing Factory

"InventoryBot has been a year in the making and has tools that provide users with everything from 'direct print' to the management of complex multi-part product construction. It is THE solution for small manufacturers looking to outsource parts creation,"

Records 1 to 15 of 39

Featured Product

Parvalux by maxon - AC or DC electric motors for conveyor systems?

The material handling industry uses conveyors to ensure that products are distributed effectively, AC or DC motors are chosen depending on the weight it needs to carry and the speed at which it needs to work. Learn which type of conveyor motor might be best for your application and how Parvalux can help you select a geared motor from stock or create a fully custom design.

.jpg)

.jpg)