From Legacy to Leading: How Manufacturers Can Bridge the Integration Gap

Despite big bets on AI, IoT and cloud platforms, many manufacturers are stuck at the starting line. Why? Because they're trying to race ahead while dragging decades-old systems behind them - and, those systems won't talk to each other.

How 3D Printing is Paving the Way for Grading Contractor, C.J. Moyna & Sons

At C.J. Moyna & Sons, being on the lookout for disruptive technologies is a part of his everyday routine. When they set on a path to integrate additive manufacturing into their daily processes, the work became easier for C.J. Moyna & Sons and their sister companies.

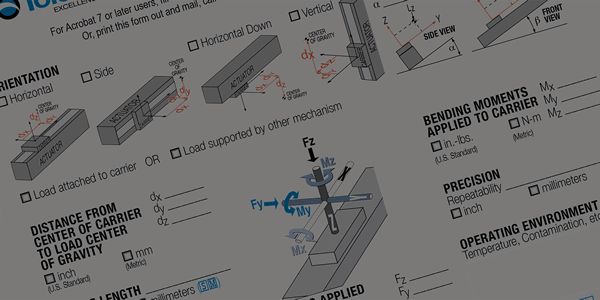

Choose an Actuator That Actually Matches Your Optimized Design

Today, many machine builders are optimizing their machine design first and then selecting an actuator based on that design. Unfortunately, however, many off-the-shelf actuators don't meet their design requirements in an optimal way

Control System Migrations | Procurement Specification & Vendor Selection

From deciding whether to handle tasks internally or outsource them, to selecting the right vendor(s) and structuring procurement, each decision plays a vital role in the overall success of the project.

Benefits of Gearbox Customisation for OEMs

A customised gearbox not only increases the life-span of existing hardware, but it can be designed to evolve and develop alongside the needs and goals of the business.

3D Printing Platform Could Shape the Future of Spare Part Production

The use of 3D printing technology to enable the fast availability of spare parts - when needed, where needed, in exactly the right quantity needed, is now, thanks to German company Replique, becoming a reality.

Records 1 to 6 of 6

Featured Product

Datanomix Production Monitoring

Datanomix Production Monitoring delivers instant visibility into your shop floor performance. Through real-time alerts, simple machine connectivity, and our kick-ass coaching, you'll catch inefficiencies early, align your team with meaningful metrics, and respond faster to issues before they escalate. The software adapts without operator input and works out of the box with purpose-built Tracks (Efficiency, Delivery, Tooling, and more). Production Monitoring arms you with the data to make more, waste less, and lead with confidence. And while real-time visibility keeps you sharp in the moment, historical insights ensure you're learning from the past to drive ongoing continuous improvement.

Manufacturing and Automation - Featured Company

CSP US Inc.

As a software manufacturer, CSP GmbH & Co. KG offers its customers bespoke solutions for the discrete manufacturing applications. This makes it easy to secure and document the quality of production processes - from development to delivery!

.jpg)