9 Evidence-Backed Predictions for the Next Decade of Auto Part Manufacturing

As the industry navigates the next decade, it will adapt to the digital transformation and the emergence of smart vehicles. Here are nine evidence-backed predictions for the next 10 years of auto part manufacturing.

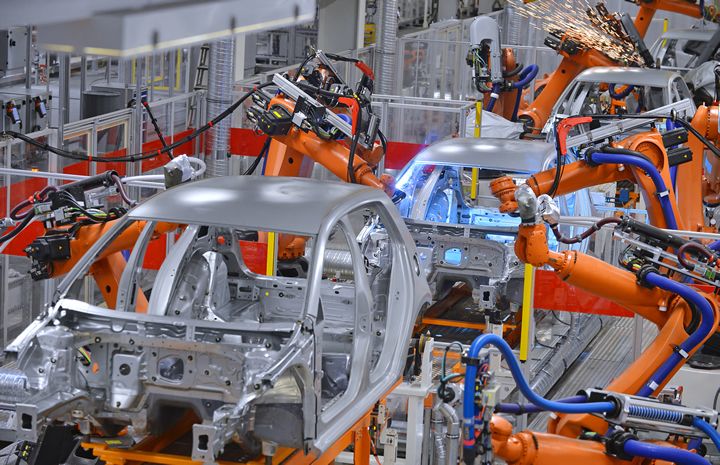

UK's Auto Factories Embrace the Advanced Robotics Revolution

The United Kingdom's automotive production sector is experiencing a fifth industrial revolution (5IR). Although the fourth industrial revolution (4IR) started just over one decade ago, the next generation of advanced robotics in manufacturing has already arrived.

The Future of Automotive Supply Chains: Integrating Sustainability with Operational Efficiency

The automotive industry is at a pivotal crossroads, driven by rapid advancements in vehicle technology and increasing regulatory pressure. As the landscape evolves, automotive manufacturers must adapt their business models and supply chains to remain competitive.

3D Printing and Sustainable Auto Manufacturing: A Glimpse into the Future

The excitement around 3D printing in the automotive industry is easier to understand in light of growing sustainability needs. While vehicles themselves may be the most obvious target for emissions reductions in this sector, the production side needs improvement, too.

Audi Sport Accelerates Design and Production Processes with trinckle Software and UltiMaker 3D Printers

When the new Audi E-Tron GT was introduced, the Audi Sport BÃ'llinger Höfe location in Heilbronn, Germany, rapidly needed almost 200 new tools, jigs and fixtures for its production. Designing these tools costs a lot of time.

Zebra Survey Shows Eight-in-10 Millennials Expect More Transparency in Automotive Manufacturing

Study reveals high demand for knowing the origin and sustainability level of materials and automotive parts as well as receiving an end-to-end view of the manufacturing process

3D Printing New Parts for a Classic Ferrari

For this particular project, Dan Nobles and Slice Engineering decided carbon fiber nylon filament would be the best option. Engineered for its intense durability and stability, a carbon fiber nylon material would be capable of handling the high-heat experienced in an engine.

Exploring the Potential of Smart Factories for Modern Auto Manufacturing

Smart factories, in particular, could transform the automaking industry to reach its full potential. As the sector grows more competitive, manufacturers that embrace this trend early could see promising results.

Turning Automotive Manufacturing Upside-down

The use of AM for production of spare parts does not sound as sexy as AM for racing cars, but the practical implications are enormous. That's especially true when it comes to spare parts for cars that have been on the road for more than a few years.

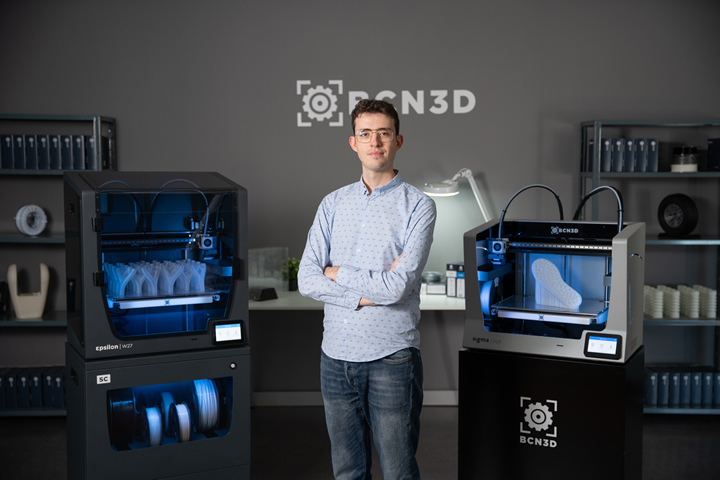

Overcoming the crisis: COVID-19, the automotive industry and the potential of additive manufacturing

In this feature, Eric Pallar©s, Chief Technology Officer at BCN3D, considers the impact of this tumultuous year on the automotive industry and how additive manufacturing can help.

Keeping an Eye on Electronics

Wherever there is electrical current, there are always electromagnetic pulses. They can have an extremely disruptive effect, e.g. on the ubiquitous electronic devices that surround us. This is why vehicle manufacturers need to verify the EMC of their products.

3D Printing in Automotive Market to Be Worth US$8 Bn By 2024

The growing need for developing complex and high-quality components while keeping the manufacturing costs low is a primary factor driving the demand for the 3D printing solutions in the automotive sector.

LK HORIZONTAL-ARM CMM INSPECTS NEXT-GENERATION AUTOMOTIVE FIXTURES

RapidFit modular gaging and holding fixtures with 3D printed locators provide major benefits in vehicle manufacture.

Building Cars in the 21st Century

Automobile manufacturing as we know it is failing; can microfactories be the answer to how we make the mobility products of the future?

ADAC Automotive Innovative Engineering with ATOS

Within a few seconds of viewing a color map in ATOS, were able to quickly understand how our actual part measures up to its design.

Records 1 to 15 of 15

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.

.jpg)

.jpg)

.jpg)