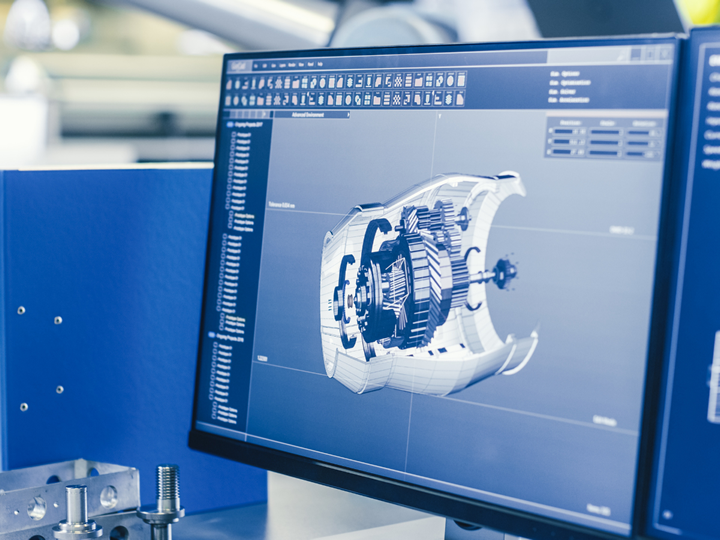

Indian Aircraft Manufacturing Company Raphe mPhibr Revolutionizes Unmanned Aerial Vehicle Innovation with Dassault Systèmes' 3DEXPERIENCE Platform

Dassault Systèmes' 3DEXPERIENCE platform helped Raphe mPhibr reduce prototype development time from years to three months. The 3DEXPERIENCE platform integrates design, simulation and collaboration, supporting in-house design and manufacturing

Rewriting the Rules of Scalable Manufacturing

The project, which fused AM-driven computational design with production-grade investment casting, successfully scaled an intricately engineered part from tens to thousands per day - all without compromising performance, cost-efficiency, or sustainability.

Securing Intellectual Property in 3D Printing: A New Era of Protection

By decentralizing manufacturing and leveraging external service bureaus, companies can deliver products faster and tailor offerings. However, due to both its quick, cost-effective, and precise manufacturing process, 3D printing is a fine target for counterfeiting.

AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

Additive Manufacture: In-house 3D Printing versus Outsourced 3D Printing Service

In this 3-part series of articles, we will embark on a comprehensive exploration of 3D printing / additive manufacturing (AM), where our main focus is empowering you to make informed decisions about how to engage with the technology across an ever-evolving landscape.

3D Printing Powers Wind Turbine Research At TU Berlin

On average, wind turbine blades are a massive 80 meters long. When it comes to reengineering these towering blades, no other technology offers the freedom, precision, and adaptability to scale parts quite like 3D printing.

Integrating 3d Printing Into Prototyping & Production Scenarios - an Interview With Iterate Design and Innovation

In this article, we discuss all things 3D printing with Gethin Roberts, Managing Director at ITERATE, and a 20 year plus veteran working in the rapid product development / 3D printing niche.

Unlocking the Value Potential of Additive Manufacturing

Still seen primarily as a prototyping technology, additive manufacturing is getting a boost from AI and machine learning software that can help with AM decision making.

Proving Out Metal AM for Distributed Manufacturing on a Global Scale

Network of contract manufacturers enables IMI Critical and Velo3D to print the same certified part in six locations and three different countries

Mattel Innovates the Toys of Tomorrow with MakerBot 3D Printers

Before having a 3D printer at his fingertips, Jack relied solely on the machine shop at the office to support his prototyping needs. Since other teams also utilized the machine shop, sometimes it would take days before he received his part back.

Metal Fabrication Shop Utilizes Efficient Production Method

When a client needs a prototype created quickly, longer-running fabrication jobs most likely will have to be be put on hold to make room for a rapid prototype manufacturing job.

The challenges of mass customization in manufacturing

Smart manufacturers have already been aware that mass customization can be the key to a profitable business, as it helps boost customer satisfaction and win brand loyalty.

Why Binder Jetting?

Besides being fast and capable of manufacturing complex shapes, binder jetting systems are also incredibly accurate.

Prestigious 140+ Year Old University Delivers Advanced Engineering and Technical Training With Method X

Karlsruhe University of Applied Sciences enriches Additive Design and Manufacturing Courses with MakerBot 3D printers. Students use METHOD X for a range of prototyping applications in research and development, industry thesis projects, and more.

At Your Service: How Turnkey Solutions Help to Unlock Additive Manufacturing for All

One of the main trends previously predicted for 2021 is the accelerated adoption of turnkey solutions in additive manufacturing (AM). Moshe Molcho, CEO at LEO Lane, looks at how certain options can help OEMs adopt AM and examines the current offering of AM turnkey solutions.

Records 1 to 15 of 35

Featured Product

Quality assurance in the manufacturing industry

Efficiency and precision with CSP software. In the highly competitive world of manufacturing, quality assurance is a critical factor for success. CSP offers you state-of-the-art software solutions specifically designed to ensure the highest standards of quality assurance in the manufacturing industry.

Manufacturing and Automation - Featured Company

OnLogic

OnLogic is a global industrial computer manufacturer who designs highly-configurable, solution-focused computers engineered for reliability at the IoT edge. Their systems operate in the world's harshest environments, empowering customers to solve their most complex computing challenges, no matter their industry. OnLogic has helped more than 70,000 customers worldwide advance their ideas with computers that are designed to last, built to order and delivered in days.

.jpg)