Decoding the Magic of KPIs: Beyond Metrics, Towards Operational Excellence

In this article, you will find why KPIs are important, how to choose a useful KPI and why to use KPIs dashboards for easy tracking of KPIs for your packaging company.

Minimizing Unplanned Downtime: Strategies for Maximizing Productivity in Your Plant

By leveraging robust downtime tracking and analysis strategies, you can pave the way for preventative measures that detect and address potential defects in equipment promptly to protect production efficiency and safety.

Security Challenges For Smart Factories - How Does SASE Help?

This rising tide of digitization and automation is leading to major concerns around cybersecurity. Smart factories are significantly more productive and competitive, yet a lot less secure.

Do You Know the Role of Tracking in Augmented Reality?

Tracking is used in the DELMIA Augmented Experience solution to identify the equipment to be assembled or inspected. Thanks to its 3D model, it simultaneously locates several elements at once, and displays the digital information required for the industrial process.

The most compact Motion Control System on the market

FAULHABER is introducing a new Motion Control System. More precisely: The world's smallest Integrated Motion Controller.

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

The key difference between preventive maintenance and predictive maintenance is that the latter means completing maintenance only when needed, as opposed to scheduled intervals.

Revolutionizing Sustainability: igus Unveils AI-Driven Solutions for Industry 4.0 at Hannover Messe

Smart maintenance, low-cost robotics, AI-based online tools: igus® showcasing pioneering solutions for the lubrication-free and CO2-neutral industry and automation of tomorrow at the Hannover Messe

Lean is the Future of Manufacturing

Reducing wait times and eliminating extraneous handling and labor through lean improves your bottom line. The capital saved can then be reinvested in new and better products and processes to further improve the customer experience, which in turn fuels business growth.

How Small Manufacturers are Building a Business Case for Robotics

Smaller manufacturers are the fastest-growing area of industrial robotics today, driven by the need for new collaborative robotics systems.

How ML helps manufacturers maintain safer workplaces

This article covers the concept of machine-learning in manufacturing and highlights four use cases of ML improving workplace safety.

Factories of the future - What will manufacturing facilities look like in 2044

The landscape of manufacturing is set to evolve dramatically over the next two decades, as cutting-edge technologies redefine the way we produce goods. To envision what the future may look like, we do not need to rely solely on idle speculation.

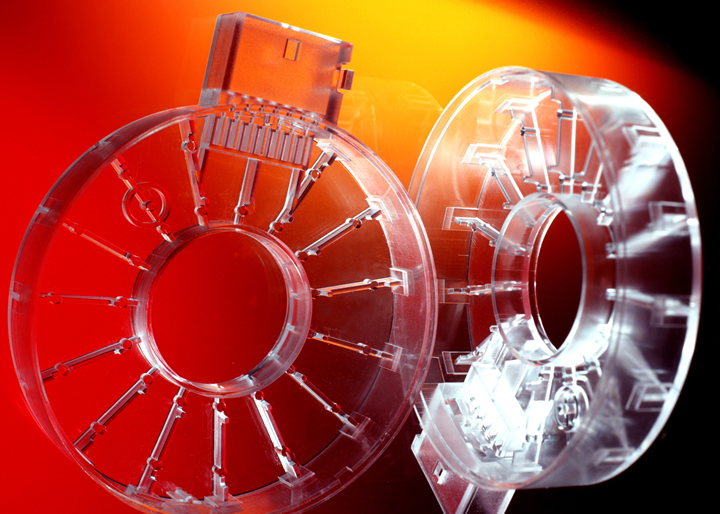

THE IMPACT OF 3D PRINTING ON MICRO MOLDING - A SYNERGISTIC APPROACH

The precision achieved in micro molding is not just about miniaturization, it's about reproducing complex shapes with exacting tolerances that are measured in microns repeatably.

The Benefits of MOM & MES and Why the Differences Matter

Mike Bradford Strategic Business Development Director at DELMIA, takes a closer look at some of the biggest differences between MES and MOM, and why these differences are critical to manufacturing success.

AI Capabilities Your Manufacturing Organization Likely Hasn't Thought About

Aside from its data-rich mining and productivity enhancements, AI can provide advantageous returns to further aid and elevate day-to-day processes.

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers, Part III

Once you've pinpointed what you will automate, it's time to develop a project roadmap. Here is how to best transform your preparatory efforts into an actionable plan:

Records 1 to 15 of 747

Engineering - Featured Product

EXAIR ATEX Cabinet Coolers

ATEX Cabinet Coolers meet the stringent ATEX requirements for use with classified enclosure purge and pressurization systems in Zone 2 and 22 explosive environments in 1,000 thru 5,600 Btu/hr sizes. These CE compliant coolers maintain the NEMA 4/4X integrity of your enclosure and are available in continuous operation and thermostat control models. https://exair.co/184_545

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)