How Real-Time Manufacturing Operations Drive Competitive Advantage in Volatile Markets

Manufacturing executives confronting today's operational challenges recognize a fundamental truth: traditional execution systems designed for stable markets have become organizational liabilities.

How to Achieve Sustainable Production?

By leveraging cutting-edge digital solutions, sustainable production transforms traditional manufacturing processes by increasing efficiency, reducing waste, and conserving energy, pushing industries toward a more resilient and eco-friendly future.

Enhancing Operational Visibility with MOM & MES Synergy

The integration of MOM and MES offers a transformative potential for manufacturing operations. By integrating these systems, companies can achieve enhanced operational visibility, improved efficiency, and better decision-making capabilities.

Driving Quality Control Excellence with MOM Integration

With MOM integration, compliance with regulatory standards becomes more manageable. Automated data collection and reporting streamline the process of preparing for audits and maintaining certification requirements.

The Benefits of MOM & MES and Why the Differences Matter

Mike Bradford Strategic Business Development Director at DELMIA, takes a closer look at some of the biggest differences between MES and MOM, and why these differences are critical to manufacturing success.

What Is MES & Why Should Manufacturers Invest In It?

Whilst MES has established itself with some of the major manufacturers, there's still a large number of businesses that could stand to benefit from the solution but simply don't have enough understanding about the tangible benefits it can bring to their operation.

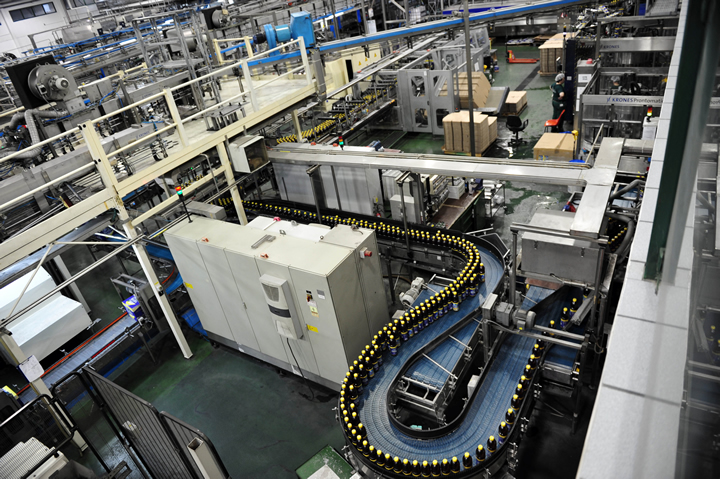

Industry 4.0: Embracing a Smarter Future

Our software brings a fundamental impact from three perspectives: process and product quality control, production optimization, and the agility required for quick responses to market opportunities and contingencies.

How to get more out of MOM with IIOT & Connected Applications

Mike Bradford, Strategic Business Development Director at DELMIA gave us his expert insight on the impact IIOT can have on a manufacturing firm when used effectively, and how this can provide a real return on investment for business owners.

Records 1 to 8 of 8

Featured Product

Super Air Knife Replaces Blowers & Saves Energy

Super Air Knife reduces compressed air usage & noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across entire length.

https://exair.co/184_523

Manufacturing and Automation - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.

.jpg)

.jpg)