Industrial Metaverse: Pioneering Remote Maintenance Solutions

The Industrial Metaverse is emerging as a transformative technology in manufacturing and maintenance, blending advanced technologies to create a more efficient and responsive operational landscape.

Revolutionizing Sustainability: igus Unveils AI-Driven Solutions for Industry 4.0 at Hannover Messe

Smart maintenance, low-cost robotics, AI-based online tools: igus® showcasing pioneering solutions for the lubrication-free and CO2-neutral industry and automation of tomorrow at the Hannover Messe

Best Practices for Safer Factories in 2024: How to Improve Material Handling Applications

This article outlines the top tips to apply in the year ahead and improve cart safety through proper caster selection, maintenance, replacement, and training.

5 Types Of Preventative Maintenance In Commercial Facilities

Knowing which method of preventative maintenance to use isn't always a straightforward decision. Depending on the complexity and value of your equipment and the possibility of compliance requirements, you might use more than one approach.

What Is Preventive Maintenance?

Michael Davies, Iota Communications: Even if you're already practicing preventive maintenance, there's still more you can do to maximize equipment uptime and utilization rates. In this article we'll cover the basics.

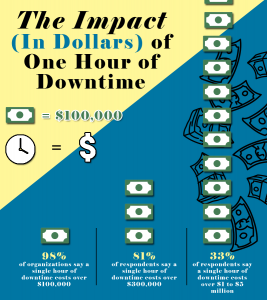

Big Picture Benefits of a CMMS

CMMS (Computerized Management Maintenance Software) is the ultimate tool in a maintenance technician's tool belt - a cure for the tedious tasks and daily issues of a maintenance department.

Records 1 to 6 of 6

Featured Product

Prototek IQ - Digital Manufacturing Services

Prototek IQ is our new instant quoting platform that simplifies your manufacturing process. With just a few clicks, you can get accurate quotes for 3D printing and CNC machining, which are currently two different platforms. Our easy-to-use interface helps you make smart choices. Use Prototek IQ to improve efficiency and streamline speed to market. We invite customers with experience in large projects, 3D printing, and CNC machining, as well as those with repeat orders, to try our instant quoting platform. You can choose our engineer-assisted quote option if you have unique needs, such as high quantities, specific quality standards, fast delivery, or special finishes.