VTT: Five percent of spare parts could currently be stored in digital warehouses.

VTT Research: Five percent of spare parts could currently be stored in digital warehouses. This would make parts more quickly and easily available, while creating considerable cost savings. Digitalisation will also enable individual customisation and an increase in the intelligence of parts.

VTT Research: Five percent of spare parts could currently be stored in digital warehouses. This would make parts more quickly and easily available, while creating considerable cost savings. Digitalisation will also enable individual customisation and an increase in the intelligence of parts.

A two-year project involving companies, and led by VTT Technical Research Centre of Finland and Aalto University, investigated how businesses can gain a competitive advantage from digital spare parts.

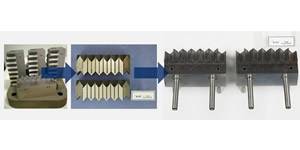

Spare parts and all of the related information can be stored and transferred digitally. Availability increases when a new spare part can be 3D-printed according to need, close to the end user.

"Industry now has every opportunity to boost business by making spare parts into a focus area of development. Around five percent of parts can currently be manufactured digitally, according to need. 3D printing technology has reached the stage where high-quality manufacturing is possible," says Sini Metsä-Kortelainen, VTT's project manager for the project.

Big production plants maintain large spare-part warehouses, where a vast number of parts wait for long periods before being used. Full Article:

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product