Increasing Demand for Medical 3D Printed Parts Requires Effective Finishing Methods

As the implementation of advanced manufacturing methods like AM increases, it is important to investigate and apply production methods that can produce intricate, yet reliable parts quickly and cost-effectively.

Keys to Biocompatible and Hypoallergenic Manufacturing

The materials approved for use in biomedical implants are limited, but as new alloys and polymers emerge, the chances are high that many of them will prove to be biocompatible as well. These will help to shape the future of biomedical manufacturing as a whole.

The Massive Potential of 3D Printing in the Healthcare Industry

While 3D printing is already used extensively in the healthcare industry, as technology advances and becomes more refined, we are likely to see amazing results.

The Top 4 Applications of 3D Printing Technology from Education, Medicine, Industry to Art

The impending uses of 3D printing are still being exposed. This article highlights some of the applications presently under way that are probable to be in general use first.

Inkbit Raises $12 Million in Equity Round Led by Stratasys and DSM Venturing to Propel Production of Its Vision-Based, Artificial Intelligence Additive Manufacturing Platform

Proceeds will be used to industrialize Inkbit's additive manufacturing system to fit the requirements of multi-material and volume manufacturing, expand the set of materials for medical, life sciences and robotics applications and install the first units for customers.

Quest For Manufacturing Human Tissue In Space Via 3D Printer to Be Launched In July

Though the prospect of manufacturing hearts and other organs via a 3D bioprinter is likely a decade away, the July launch is a significant milestone in that quest.

PrinterPrezz Opens First Bay Area 3D Print and Nanotech Innovation Center for Design, Development and Manufacturing of Advanced Medical Devices

"3D printing has the potential to revolutionize how the world thinks about developing advanced medical devices, but in the current ecosystem, it takes too long to go from concept to product," said Shri Shetty, co-founder and CEO of PrinterPrezz.

Stratasys and Materialise: 3D Printed Medical Models Come to Life

Stratasys PolyJet technology and Materialise FDA-cleared software now most versatile 3D printing system for hospitals and physicians to build anatomical models at the point-of-care

3D Printing for Surgical Procedures

3D printing is becoming the standard in preparing for surgical procedures, using patient-specific models, and implanting devices and tissue during the operation with the help of surgical guides.

3d Modelling and Printing - Saving Theatre Time and Providing Excellent Patient Outcomes

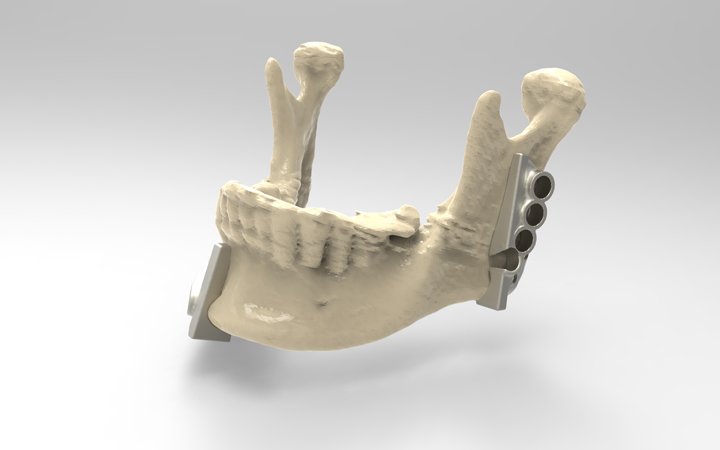

In a recent project, Renishaw used its additive manufacturing (metal 3D printing) expertise to help the University Hospital of Wales (UHW) treat a patient who suffered cancer of the lower jaw and required removal of the affected region coupled with reconstructive work.

Records 1 to 10 of 10

Featured Product

Affordable Excellence: The Go-To Tool for Finding Compressed Air Leaks

Find compressed air leaks fast with FLIR's new cutting-edge Si1-LD acoustic imaging camera. Leveraging advanced ultrasonic technology and onboard analytics, this affordable camera pinpoints leaks and quantifies incurred losses even in the nosiest environments. Upgrade your maintenance routine with the cost-effective FLIR Si1-LD - significantly reduce energy costs and increase system uptime. Get Started Today.

.png)