The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

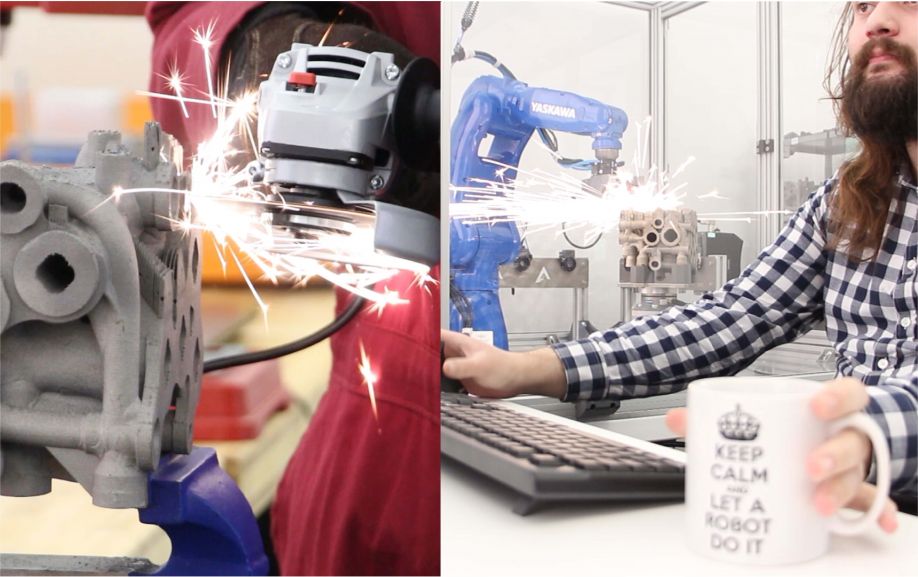

In 2024, post processing metal parts is still a bottleneck in the AM process chain because it is still very often a manual, labor-intensive, messy (filthy, actually) and sometimes risky task.

THE RISE OF AUTOMATION IN METAL AM POST-PROCESSING - TRANSFORMING THE INDUSTRY WITH PRECISION AND EFFICIENCY

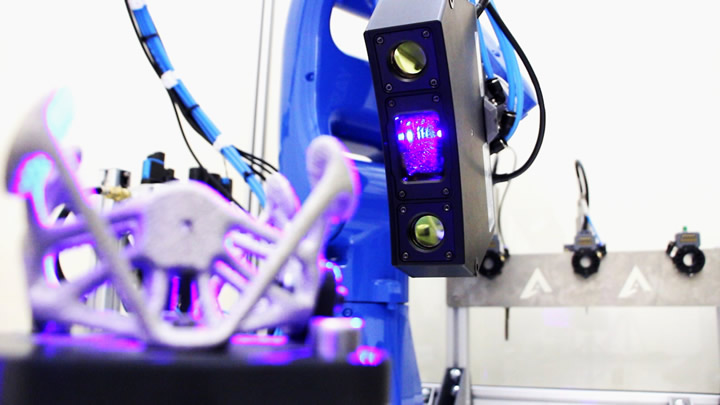

We delve into how automation in metal AM post processing is setting a new industry standard, and how companies like Rivelin Robotics are leading this change with their Netshape® Robots to unlock new productivity and efficiency gains.

REFLECTING THE FINISH: THE CRUCIAL ROLE OF POST-PROCESING IN AM

With a holistic approach that combines advanced printing technology with equally advanced finishing techniques, AM is redefining manufacturing, offering unprecedented agility, efficiency, and quality to industries around the world.

AM Post-processing: Benchmarking Alternative Technologies

With a variety of post-processing technologies available, it is essential to understand their capabilities and limitations. In this article, we will benchmark different post-processing technologies and explain why mass finishing technologies are the best fit and the most efficient solution.

Weerg achieves cycle time reductions of over 50% with post processing technologies from AM Solutions

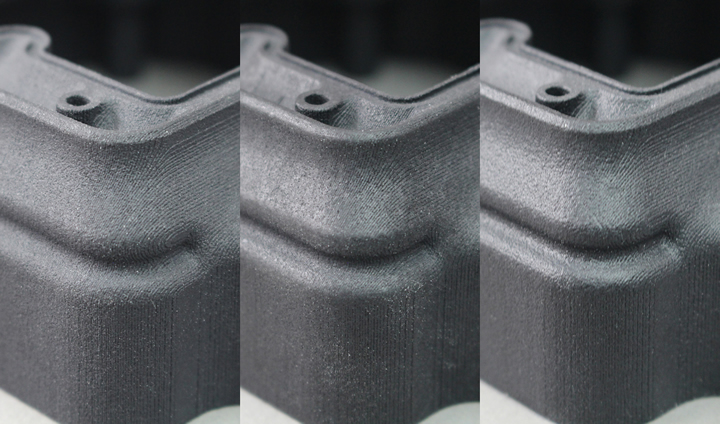

While order processing and manufacturing of the 3D components was managed digitally early-on, numerous post processing operations still had to be done manually, which required a lot of time and personnel and produced inconsistent results.

The Role of Wet Blasting in the Post-processing of AM Parts

Many companies are working on and researching new bespoke AM post-processes, sometimes with impressive results, but usually restricted in usefulness to particular materials or geometries, and almost all being highly priced and over-engineered.

AUTOMATED POST PROCESSING SOLUTIONS: PROS & CONS

There are a number of reasons to apply optional post processing to parts, including but not limited to advantages gained in terms of aesthetics, part performance,e and improved material properties.

Post Processing in 3d Printing - the Key to Viable Production Outcomes

When we specifically consider the use of 3D printing for production applications, the industrial 3D printing machines themselves are actually just one part of an extensive ecosystem of technologies that enable the production of parts, both pre- and post-build.

Post-processing - Enabling Additive Manufacturing

In this article, Joseph Crabtree, CEO at Additive Manufacturing Technologies Ltd considers the importance of post-processing in the entire production process chain and highlights an emerging solution.

Records 1 to 9 of 9

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

.jpg)