What is the advantage of buying linear guideways with integrated linear encoder pre-installed?

Direct measurement is usually favorable over indirect position measurement. In the case of integrating direct position measurement, there are two primary methods of adding position measurement to an axis.

From Ready-Made Motion Code to Built-In Diagnostics, Unitronics 'Servo Made Simple' Increases Profit - By Saving Time.

Say goodbye to complexity-you can now benefit from Plug-and-Play integration, and remotely commission, configure, program, run, and troubleshoot your motion control systems. Meet Servo Made Simple from Unitronics.

SUPPLIER SELECTION FOR CRITICAL MOTION CONTROL APPLICATIONS

In this article, I attempt to arm manufacturers with the questions that they need to ask to ensure that the motion control solution option chosen is right first time and up to the job. These questions should ideally focus on not just capabilities but also values.

5 Advantages of Using EtherCAT for Motion Control

EtherCAT is proven to optimize machine performance with its deterministic performance, flexible topology, and diverse set of features. To better understand why users should use EtherCAT, let's review its history, how it works, and the problems it solves.

VFDs-How Smart Selection Saves on Costs

Integrating VFDs into your applications enables you to implement robust, precise control that cuts your energy requirements; built-in communication-based control reduces your wiring and IO modules costs.

High Precision Linear Motor Stages for Industrial Automation

Precision industrial motion systems are used in test, assembly or laser micro-machining of high precision and high value components and in electronics, optics, and photonics manufacturing, to name a few.

Discussing ATX West with HEIDENHAIN

Motion control is at the core of automation technology. Whether it is 3D printing, robotics, semiconductor manufacturing or machine tools, HEIDENHAIN offers the precision feedback in both linear and angular, as well as positioning systems and controls. Booth #4466

Ultra-Precision Motion Control - Key Considerations for Supplier Selection

As the demand for more and more exacting motion control increases across numerous industry sectors, it is vital that before investing, customers are informed enough to make sure that they select the right solution for their specific application.

Encoders Hold the Key to Ultra-accurate Motion Control

Aerotech, continuing its commitment to the art and science of motion control, looks to Renishaw for versatile, high-precision laser interferometer encoders for its medical stages.

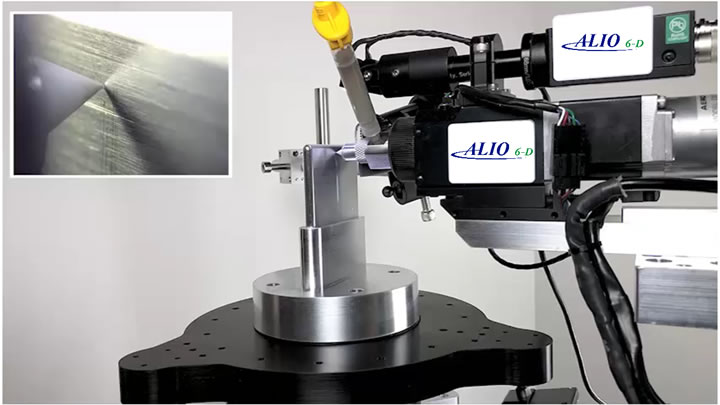

Applications of Nanometer-Level Precision Motion Control Solutions

Crucial to many exacting applications requiring nanometer-level accuracy and repeatability are best-in-class motion control solutions. This article will look at the top-end solution in terms of accuracy and repeatability...

Celera Motion Case Study - Precision Rotary Axis Control

The customer required precision rotary axis control in the lowest profile form factor for multiple sequential robot arm joints. Key additional requirements included minimal movement at start-up to report absolute position...

Top Article for 2018 - Machine Automation Explained

Motion control systems are ideal for use in applications that require product positioning, rapid start and stop motions and synchronization of unconnected elements. PLCs have the capability to offer the required signals for commanding stepper systems and servos...

Next Generation Motion Control - Achieving the Impossible

This article reviews the motion control scene, and places the introduction of the Hybrid Hexapod® in context for pan-industrial manufacturers working at the bleeding edge of precision and repeatability.

How Advanced Precision Motors Empower the IoT and Industry 4.0

The need for precise motion control is driven by many demands now placed on the line, from moving products around on the manufacturing floor to a variety of work stations to the logistics of moving the finished product through a facility.

RTOS 101: Performance Analysis with Tracealyzer

When developing firmware using a Real-Time Operating System (RTOS), how do you measure the software performance?

Records 1 to 15 of 24

Featured Product

Parvalux by maxon - AC or DC electric motors for conveyor systems?

The material handling industry uses conveyors to ensure that products are distributed effectively, AC or DC motors are chosen depending on the weight it needs to carry and the speed at which it needs to work. Learn which type of conveyor motor might be best for your application and how Parvalux can help you select a geared motor from stock or create a fully custom design.

.jpg)