Motion feedback really is everywhere - Here's how encoders help make beer

When you buy the best equipment, you want the best components, too. That's why Community Beer Company uses an EPC encoder in their brewing equipment.

Considerations for Choosing the Right Encoder for Your Application

Depending on the encoder, resolution is one of the most important calculations to understand. Accurate print landing, accurate conveyor speed, accurate satellite positioning, accurate elevator control all hinge on the resolution and type of encoder.

SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

As Everest Labs was developing their system to be sold to recycling centers worldwide, they found that their robot needed speed feedback in order to track the recyclables on the conveyor, and therefore needed a simple way to install conveyor speed feedback on a gear motor.

Best Practices for Encoder Mounting

By following mounting best practices, designers can be sure that their feedback loop is providing accurate data that will enable the system to meet topline performance levels.

Encoders Hold the Key to Ultra-accurate Motion Control

Aerotech, continuing its commitment to the art and science of motion control, looks to Renishaw for versatile, high-precision laser interferometer encoders for its medical stages.

Case Study: Programmable Model 25SP Saves the Day!

EPC's Accu-CoderPro™ programmable encoders are specifically designed for the challenges of an industrial environment. Contained within the rugged, industrial housing is an advanced set of electronics that allow the encoders to be programmed to your exact application needs.

Is There a Maximum Length of Encoder Cables?

There is no general answer concerning the maximum cable length. A cable length of up to 10 m can be handled without any problems if some special measures are taken into account. Even cable lengths up to 50 or 100 m have been successfully in use ...

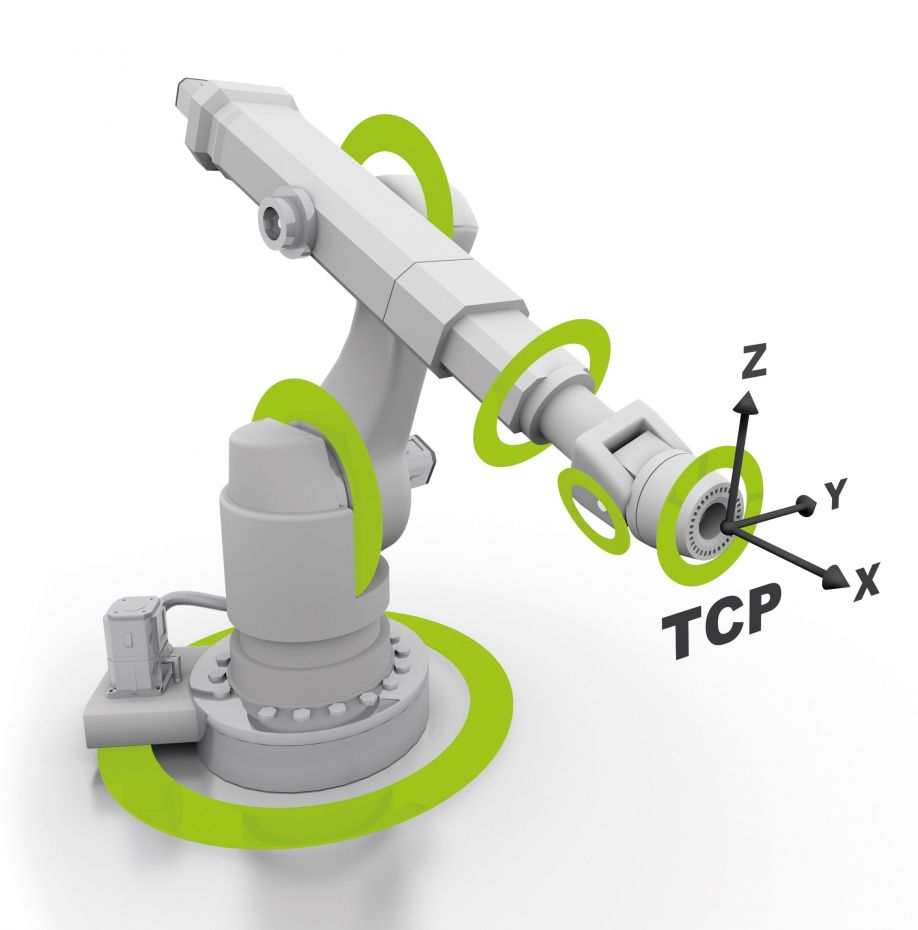

Industrial Robots: Encoders for Tool Center Point Accuracy

The use of secondary encoders on all of a robots axes, as well as the use of linear encoders for positioning the robot relative to the workpiece, enables a high level of accuracy at the tool center point

Industrial Robots: Encoders for Tool Center Point Accuracy

The use of secondary encoders on all of a robots axes, as well as the use of linear encoders for positioning the robot relative to the workpiece, enables a level of accuracy at the tool center point

Records 1 to 9 of 9

Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.

.jpg)