Practical Reverse Engineering - Choosing the Right Tools for the Job

In the big picture, RE is a subset of digital measurement, which is the driver behind other manufacturing applications, including quality inspection, tool building, assembly guidance, and more.

Reverse Engineering for a Model-Based World

The list of reverse engineering applications is long and will continue to grow as engineers create new and creative ways to use the technology.

3D Systems Announces First-to-Market Enhancements to Reverse Engineering Software - Enabling Increased Efficiency & Accuracy across Broad Application Portfolio

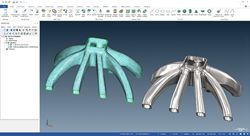

-Unique unroll/reroll function in Geomagic® Design X enables a new modeling workflow for complex revolved parts resulting in a 94% efficiency improvement.

-Geomagic Design X's new features for hybrid surfacing workflows accelerate productivity, improve downstream CAD re-usability

Rebuilding Components With Reverse Engineering

Rebuilding components with Reverse Engineering, LS technology and Windform® composite materials: how advanced technologies allow companies to save time and money.

Records 1 to 4 of 4

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.