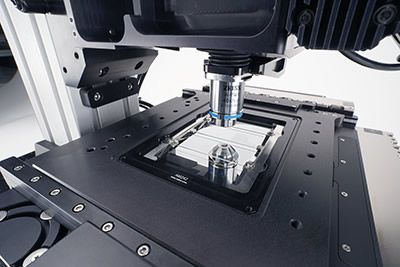

Case Study: Affordable Dual-View Microscope System

Zaber's Nucleus® microscopy modules share a common control protocol mounting features, and optical and electrical interfaces, enabling them to be combined in ways that are simply not possible with other microscopes.

Validation & Quality Control: Optimizing Micro Molding Outcomes

But there is one aspect of a micro molding project that is often overlooked, especially when customers are assessing the in-house capabilities of a micro molding partner, and that is validation and quality control.

The Critical Role of Metrology in Product Development - a Case Study

During the development process, Metronom recognized the critical role of metrology in both R&D and production quality control for its CGM. When working at a scale that is difficult to image with traditional microscopes.

Additive Manufacturing - New Frontiers for Production & Validation

AM has enabled concurrent engineering"•where all relevant departments can be engaged early in the product development process. Concurrent engineering replaces traditional "over-the-wall" product development, where design iterations could be delayed by weeks.

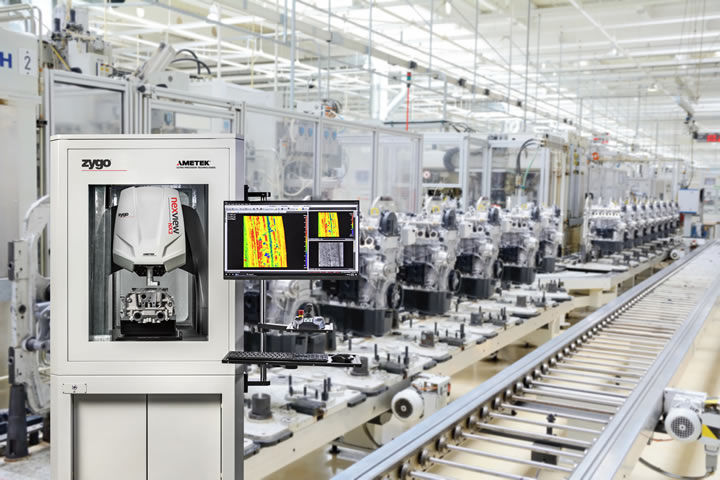

METROLOGY & INDUSTRY 4.0

Today's most sophisticated metrology systems drive quality assurance (QA) which has become a fundamental digital task which in and of itself facilitates efficient and cost-effective production processes.

METROLOGY FOR MICRO MOLDING - A CASE STUDY

Eric Felkel, Product Manager, ZYGO Corporation

3D Optical Metrology - Versatile Tools for Today's Advanced Manufacturing

When looking at metrology, general discussion often revolves around the relative merits of contact or non-contact measurement solutions. There is now a drive across nearly all industries for smaller and more complex components.

Automotive Control System Manufacturer Invests in Mulit-sensor Inspection

To upgrade the inspection capabilities of its measurement laboratory, the quality department at the Chassis & Safety division of automotive equipment manufacturer Continental invested in two LK Metrology ALTERA multi=-sensor coordinate measuring machines (CMMs).

Records 1 to 8 of 8

Featured Product

MRPeasy - ERP for Small Manufacturers That Delivers Results

Always know what you have in stock and what you'll need to fulfill orders. Never forget to order parts on time or fail to notice a late delivery from your vendor. Easily create manufacturing orders and schedule them automatically according to resource availability or delivery deadline. Generate accurate cost and lead time estimates and provide customers with quick quotes. Receive notifications when orders are late or inventory levels reach a critical point. Ensure seamless communication between sales, production, warehousing, procurement, administration, and finance. Integrate with popular accounting, CRM, and e-commerce apps. MRPeasy is an ERP software for small manufacturers that gives you all that and more. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries. Try for free, no credit card needed.

Manufacturing and Automation - Featured Company

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.