Acquiring Accurate Measurements in Manufacturing with Mate Gauge

Mate Gauge created an inline solution for fast, accurate and reliable laser measuring. The solution offers a touchscreen user interface to show data and charts of thickness changes over time.

Precise Load and Force Measurement in Smart Hydraulic and Electric Actuators

Throughout history, there have been industrial applications that require a load or force measurement within a system that involves either linear electric or hydraulic smart actuators.

The Right Choice 40 Years Ago. The Right Choice for the Next 40 Years

By working with Leslie Controls, a customer protected their original investment and was able to work through the plant re-certification process cost-effectively

ZEISS to build new state-of-the-art facility in the Detroit metro area

The new center will provide a broad portfolio of dimensional metrology and inspection equipment and services to a wide variety of industries including: automotive, medical, aerospace, defense, machine tools and general manufacturing job shops. With almost 170 employees.

Tame Your Energy Hog with Accurate Compressed Air Measurement

As most facilities managers can attest to, the electricity used to produce compressed air can be one of the most expensive energy costs in your facility.

Why is Calibration and Validation Important in Manufacturing Industry

Manufacturing industry has to ensure that all the products being manufactured are of high quality, right specifications and perform the required functions. Two processes help in ensuring that - instrument calibration and validation.

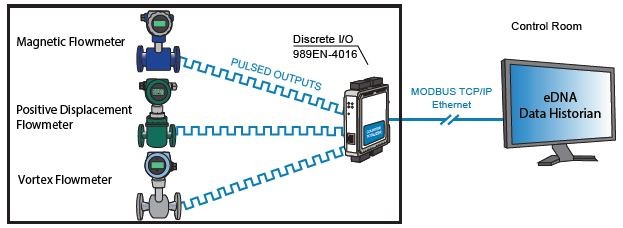

Twin Totalizers Send Your Flow Meter Pulse or Analog Signals to the Network for Metering or IIoT Remote Monitoring

Increasingly in the age of energy management in process, manufacturing and BAS, the need for companies and organizations to not only record and manage the energy or water usage but also sub-meter, an Ethernet transmitter with totalizer function is essential.

Records 1 to 7 of 7

Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.