Energy consumption is growing exponentially, while energy creation is increasing only incrementally. This imbalance requires innovative solutions. At Delta, we tackle this challenge from both sides—enhancing energy creation while optimizing energy consumption.

Energy Efficiency in Manufacturing and Data Management

Energy Efficiency in Manufacturing and Data Management

Q&A with Victor Lee, Senior Vice President of Data Center Strategic Business Platform | Delta Electronics

Tell us about yourself and Delta Electronics.

I hold a Master of Science in Electrical Engineering from Rutgers University and an MBA from Baylor University. My career began at Bell Laboratories in New Jersey, where I was fortunate to choose my area of expertise. I selected magnetics—a field with significant untapped potential—and focused on transformers, power supplies, and power converters, including DC-DC and AC converters.

In 2001, I founded Innoveta, a company dedicated to high-density power modules. The name Innoveta stems from "innovation" and "eta" (efficiency), reflecting our mission. Together with 20 former Bell Labs colleagues, we built a thriving business in Plano, Texas. A few years later, TDK acquired Innoveta, and I remained as CEO of TDK Innoveta for five years. I then joined Emerson Network Power as Group CTO, overseeing engineering and technology for a $6 billion energy business group.

Today, I serve as the Senior Vice President for the Data Center Strategic Platform at Delta Electronics. Delta is committed to developing innovative, clean, and energy-efficient solutions, particularly in data center infrastructure. My focus is on driving forward-thinking strategies and impactful innovations to meet the challenges of an ever-evolving industry. Throughout my career, I have had the privilege of contributing to key technological advancements and hold 21 U.S. patents in data center infrastructure.

Delta recently announced a significant investment in a new R&D and manufacturing facility in Plano, Texas. How does this expansion strengthen Delta's commitment to U.S. manufacturing?

I’m truly excited about Delta’s expansion in Plano, Texas, as it reflects our long-term commitment to U.S. manufacturing and innovation. This investment includes a 477,000-square-foot manufacturing plant and a 90,000-square-foot office building, set for completion by 2027. We plan to follow this with another 477,000-square-foot facility by 2029. Ultimately, our Plano campus will span 42 acres, covering nearly 1.5 million square feet and supporting over 2,500 local jobs.

Beyond expanding our manufacturing footprint, this investment strengthens our R&D presence in the U.S. Delta operates a truly global R&D model, with teams across the U.S., Asia, and Europe collaborating closely to develop cutting-edge solutions. Our researchers and engineers work alongside customers and industry leaders—particularly in AI data centers and other high-growth sectors—to address real-world challenges.

This expansion also enables us to manufacture critical power and cooling products for data centers, telecom infrastructure, and EV charging stations right here in the U.S. By bringing more of our production and engineering capabilities closer to our customers, we can respond faster to their needs while upholding Delta’s reputation for high-quality, energy-efficient solutions.

Energy efficiency is increasingly important in manufacturing and data centers. How does Delta's expertise in both areas create unique value for customers?

Right now, the industry is focused on securing GPU chip availability, but as Microsoft’s CEO recently pointed out, the real bottleneck isn’t chips—it’s energy. The future of data centers depends not only on computational power but also on how efficiently we generate and consume energy.

The challenge is clear: energy consumption is growing exponentially, while energy creation is increasing only incrementally. This imbalance requires innovative solutions. At Delta, we tackle this challenge from both sides—enhancing energy creation while optimizing energy consumption.

On the energy generation side, we offer a comprehensive portfolio of solutions, including PV inverters, wind power converters, energy storage systems, EV chargers, energy IoT devices, and the DeltaGrid® energy management platform.

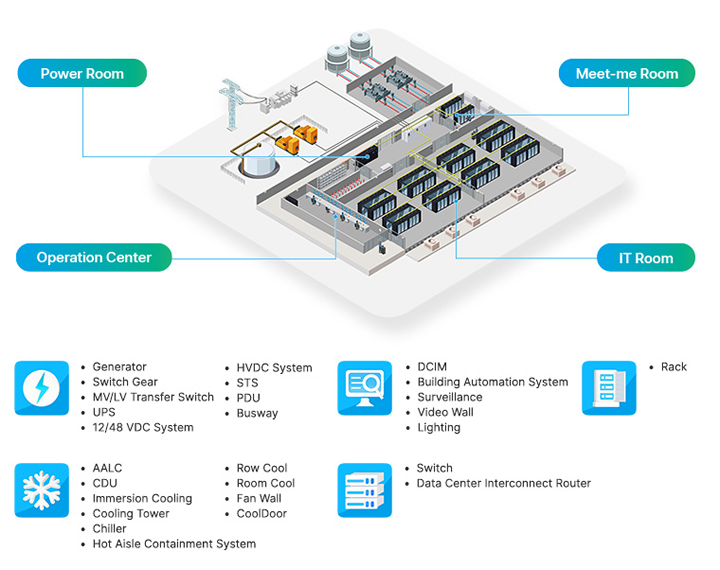

For data centers, our focus is on optimizing the "grid-to-chip" pathway. As GPU power demands increase, cooling technologies such as air cooling, cold-plate, liquid-to-air, and liquid-to-liquid solutions are being deployed. However, these solutions can introduce additional energy consumption due to the need for pumps, motors, and EC fans.

The future of efficiency goes beyond power and cooling—it requires a holistic approach to the entire system. Rather than just removing heat from chips, we need to optimize every step from power generation to final consumption. Additionally, we must consider how large-scale energy consumption for data centers affects residential areas and broader communities.

At Delta, we create value by addressing both sides of the equation—advancing sustainable energy creation while optimizing how energy is used.

How do Delta's vertically integrated manufacturing capabilities enhance data center infrastructure solutions?

Delta’s strength lies in our deep understanding of the entire power delivery chain. Our vertically integrated approach allows us to design and optimize each component to work seamlessly together, rather than relying on disparate, off-the-shelf solutions that may not be fully optimized for efficiency.

Additionally, our industrial automation group enables us to develop customized designs tailored to specific customer applications. Instead of retrofitting generic solutions, we create purpose-built infrastructure that enhances both performance and energy efficiency.

Having led world-class teams, what leadership principles have you found most valuable in driving manufacturing excellence?

One of my core leadership principles is recognizing that R&D and production require fundamentally different environments to thrive.

For R&D teams, creativity and innovation are essential. Engineers need the freedom to experiment, explore new ideas, and take calculated risks without fear of failure. This culture fosters breakthroughs in technology.

On the production side, discipline, structure, and precision are critical. We implement rigorous quality control and efficiency measures to ensure consistency, reliability, and scalability.

Balancing these two dynamics—fostering innovation while maintaining manufacturing excellence—has been key to Delta’s ability to rapidly bring cutting-edge technologies to market. As we expand operations in Plano and globally, this approach ensures that our R&D pipeline translates into high-quality, market-ready products.

How do you stay innovative in today’s fast-paced technology sector?

To me, innovation is a continuous process driven by three key principles:

- Active Involvement in Development – Staying closely engaged in R&D keeps me connected to emerging challenges and potential solutions.

- Customer Collaboration – Understanding customer pain points and future needs allows us to develop solutions that provide real, immediate value.

- Lifelong Learning – Technology evolves rapidly. Staying ahead means continuously refining my knowledge of materials, systems, and industry trends. By recognizing patterns across sectors and focusing on fundamental challenges—such as energy efficiency—we stay proactive rather than reactive.

This approach ensures that Delta remains at the forefront of power and energy management innovation, delivering solutions that anticipate market needs rather than just responding to them.

Delta’s mission statement is "To provide innovative, clean, and energy-efficient solutions for a better tomorrow." How does this vision influence your day-to-day manufacturing decisions and company culture?

Our mission isn’t just a statement—it’s a guiding principle embedded in everything we do.

In the data center industry, energy efficiency isn’t just an environmental goal; it’s a financial and operational necessity. Data center operators actively seek solutions that reduce energy consumption because it directly impacts their bottom line and sustainability goals.

At Delta, we take a holistic approach to energy efficiency—looking beyond individual components to optimize the entire system from power generation to final consumption. Our manufacturing processes reflect this commitment, ensuring that every product we deliver aligns with our vision of a more sustainable future.

Ultimately, our mission drives us to develop solutions that not only meet the immediate needs of our customers but also contribute to solving the global energy challenge. By balancing innovation with responsibility, we help shape a future where technology and sustainability go hand in hand.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product