IoT in Manufacturing: Seizing the Opportunities Amid Challenges

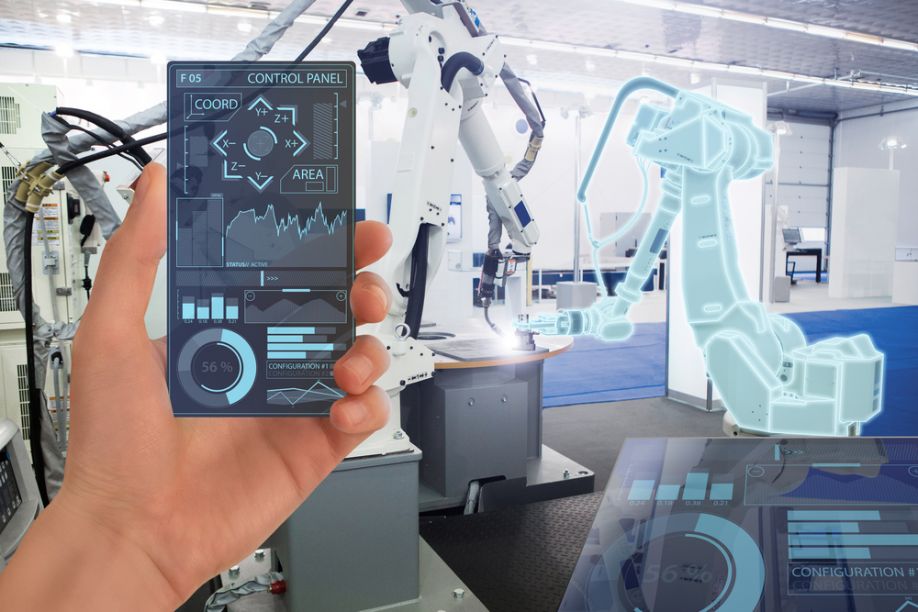

Now more than ever, manufacturers are integrating new technologies, such as IoT, cloud computing and analytics, and AI and machine learning into their production facilities and operations.

How IoT Will Elevate 8 Types of Equipment in 2023

A rising global population means a higher demand for goods and services. Companies find ways to increase production and quality control, such as through the Internet of Things.

Simplified CMM Inspection Provides a Flexible Approach to More Productive Quality Control

The simplified operator menu lists all the available inspection programs and the exact position the part should be placed on the machine table for inspection, giving operators the confidence to perform measurement tasks in just a few clicks.

Delivering IoT-Centric Factory Automation with Wi-Fi HaLow Technology

Assessing the health of capital equipment used to produce and move these goods minimizes cost repairs, downtime and outages. Businesses gain a big picture of the logistics chain using wireless sensors that provide data on the location of high-value cargo.

Getting used to the new normal with the IoT

As the country faces yet another surge of cases, manufacturers must do everything in their power to prevent outbreaks, keep their people safe and maintain operations. And the Internet of Things (IoT) can help manufacturers accomplish this lofty goal.

IoT for Small and Growing Manufacturing Firms

Operational benefits build efficiencies into the manufacturing process and strategic benefits build out new business models and revenue streams.

3 Revolutionary Advances in IoT Machine Learning

Manuel Nau for IoT Business News: Oracle is taking the IoT to a new level with the announcement that its IoT cloud service will now incorporate artificial intelligence and machine learning to provide clients with better business data insights than ever.

The Biggest Challenges of Data-Driven Manufacturing

Willy C. Shih and Helmuth Ludwig for Harvard Business Review: The widespread deployment of low-cost sensors and their connection to the internet has generated a great deal of excitement (and hype) about the future of manufacturing. The internet of things (IoT) and industrial internet in the United States, Industrie 4.0 in Germany, and 物è"网 (wù lián wăng) in China are all centered on the application of big data and analytics to creating the next generation of manufacturing: using data to reduce costs through next generation sales and operations planning, dramatically improved productivity, supply chain and distribution optimization, and new types of after-sales services. In fact, IoT is at the peak of Gartner’s 2015 hype cycle, which suggests the next phase will be disillusionment, and it will be years before we see real productivity gains.

We believe data-driven manufacturing is indeed the next wave that will drive efficient and responsive production systems. But to get beyond the hype, managers need to understand some underlying challenges and paradigm shifts. While there are a multitude of challenges on the road to successful implementation, we think there are four especially important ones. Cont'd...

Formerly the World's Most Wanted Hacker, Kevin Mitnick, Joins Keynote Lineup for East Coast's Largest Advanced Manufacturing Event

Through "Live Technology Magic Show," Mitnick to Demonstrate the Importance of Cyber Security Across Connected Manufacturing, June 16 in New York City

Jump Headfirst into Industrial IoT Projects with Moxa's 4G LTE Jump Start Kit

The new kit sharply reduces the cost and effort to connect industrial sensors and devices to cloud-connected databases and platforms

Industrial IoT Market Nears $132 Billion in 2020: Technavio

Pedro Hernandez for Datamation: The Internet of Things (IoT) is expected to have a major, efficiency- and productivity-enhancing impact on how manufacturers and other companies in industrial settings conduct businesses. A new forecast from market research firm Technavio paints a rosy picture for IT vendors that specialize in industrial IoT.

According to the analyst group, the market for industrial IoT software and services will reach nearly $132 in 2020. Between now and then, the market will expand at a compound annual growth rate (CAGR) of 7 percent.

In terms of demand, Technavio has identified the Asia-Pacific (APAC) region as the largest market for industrial IoT.

Last year, the industrial IoT market generated $38 billion in sales in the region, a number that will reach $54 billion in 2020. APAC countries are investing heavily, including South Korea, which plans to pour over $3.6 billion into the IoT by 2020. Cont'd...

Study Finds 34% of Manufacturers Do Not Track Asset Data

Smartware Group, Inc. and Technology Evaluation Centers, Inc. survey highlights missing link between maintenance practices, software capabilities

Industry 4.0: What businesses need to know

By Barclay Ballard for ITProPortal: In order for businesses to prepare for Industry 4.0, they first need to understand the technological driving forces behind it, including the Internet of Things. Although mainstream examples of IoT devices are relatively limited at the moment, in the future connected objects are expected to revolutionise a whole host of business sectors. In the same way that new manufacturing processes brought about huge upheaval during the Industrial Revolution, the Internet of Things is also predicted to bring wholesale changes to industry.

“The Industrial Internet of Things (IIoT) has been described as a crucial step in the Fourth Industrial Revolution or Industry 4.0,” explains Martyn Williams, managing director of industrial automation software expert, COPA-DATA UK. “Using IoT technology, organisations are developing smarter infrastructures and building connected networks across entire manufacturing processes.”

Some of the key changes predicted to emerge as the Internet of Things is adopted by industrial firms include the following: Cont'd...

MIT Professional Education's Online Course to Bring Latest Research on Internet of Things to Professionals

Led by MITs original architects of the Internet of Things (IoT), the new course addresses architectures, technologies and applications of IoT

Records 1 to 14 of 14

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include:

Robotics, Aerospace, Medical technology and Optical systems

.

Manufacturing and Automation - Featured Company

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

.jpg)

.jpg)