IMTS 2024 Product Preview

IMTS 2024 takes place September 9th - 14th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Learning From Visionaries: The Stages at IMTS 2024 Feature Technology, Manufacturing, and Industry Leaders

The Stages throughout IMTS feature executive conversations and presentations on AI transformation and empowerment, innovation and change management, digital transformation, growing the defense industrial base, manufacturing infrastructure, and much more.

New VERICUT® CNC Machine Connectivity Feature Improves Program Accuracy Through Digital Twin Technology

This feature of CNC Machine Connectivity, which utilizes the Scytec DataXchange machine monitoring solution, supports the analysis of digital twin simulations through the replay of stored, live-streamed data from the numerical control (NC) machine.

IMTS 2024 Offers Hidden Technology Gems, New Exhibitors

The International Manufacturing Technology Show offers an opportunity to discover unexpected solutions at more than 1,500 booths, including more than 65 first-time exhibitors offering innovative solutions.

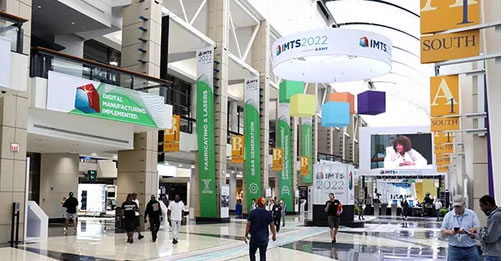

IMTS 2022 Opens Sept. 12, Showcases Digital Tech That Address Manufacturing's Biggest Challenges

Nine technology pavilions feature solutions such as multi-tasking machining centers, robots/cobots, digital twin, manufacturing software, controls, additive manufacturing, and quality control/inspection.

IMTS 2022 Product Preview

IMTS 2022 takes place September 12th - 17th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

CIMON at IMTS 2022

CIMON will feature a wall-to-wall video screen connected to our 4 product

kiosks that will allow visitors to try out CIMON hardware and software in real time. We will have sample project displays visible on the large screen.

Shop Floor Automations at IMTS 2022

The DataXchange machine monitoring software solution eliminates manual, labor-intensive processes to give manufacturers instant views and alerts about their equipment on the floor to make quick, informed decisions.

INTERNATIONAL MANUFACTURING TECHNOLOGY SHOW CANCELLED FOR FIRST TIME SINCE WWII

IMTS to continue to offer digital experiences to foster connections, networking and technical learning opportunities.

HANNOVER MESSE USA 2018: North America's Stage For Industry 4.0

Technology providers of all sizes from around the world came to HANNOVER MESSE USA 2018 to demonstrate the latest Industrial Internet of Things (IIoT) solutions for the connected factory of the future

RECORD BREAKER: IMTS 2018 LARGEST SHOW EVER

Exponential technology advances, strong economy propel

North Americas premier manufacturing show

IMTS 2018 TO BE FIRST SHOW TO FULLY OCCUPY MCCORMICK PLACE

Expanded technology pavilions, co-located shows, conferences, events and two AMTs Emerging Technology Centers; digital connectivity and additive manufacturing among hottest technologies showcased for manufacturers and job shops.

International Manufacturing Technology Show

Now, with connectivity, controls, process integration and automation, job shops and manufacturers can harness more uptime from their CNCs. Visit more than 350 companies in the Metal Cutting Pavilion.

Talking IMTS with Desktop Metal

Desktop Metal, the company committed to bringing metal 3D printing to engineers and manufacturers will be exhibiting its breakthrough technologies for both prototyping and mass production of metal parts for the first time at IMTS, Booth #432300

Talking IMTS with Omron

Booth #134845 - OMRONs flexible manufacturing demo will present several solutions designed to help companies meet the customization demands imposed by todays increasingly globalized and eCommerce-driven market.

Records 1 to 15 of 47

Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

.jpg)