COMPOSITE CONDUCTOR CORES ENABLE AMERICAN POWER MODERNIZATION

Surging electrical demand from AI-enabling data centers and increased urban power consumption, as well as vast renewable energy production, require upgraded electrical infrastructure.

Interwire 2021 Trade Exposition - Industry 4.0 in Wire Manufacturing

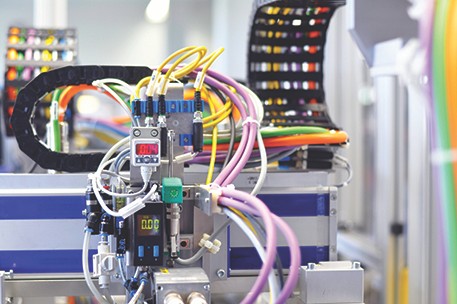

Industry 4.0 is truly the future of manufacturing. Automation, robotics, machine learning, and data analytics are just a few examples of how the fourth industrial revolution affects the way wire and cable is made and how well companies compete on the world stage.

Benefits of VFD Cables Over THHN

Cables with the proper shielding, i.e. foil plus braided shield or semi-conductive fleece with foil and a braid shield, prevent the VFD system from radiating electrical noise that can interfere with the surrounding networking, wireless communication, and industrial devices.

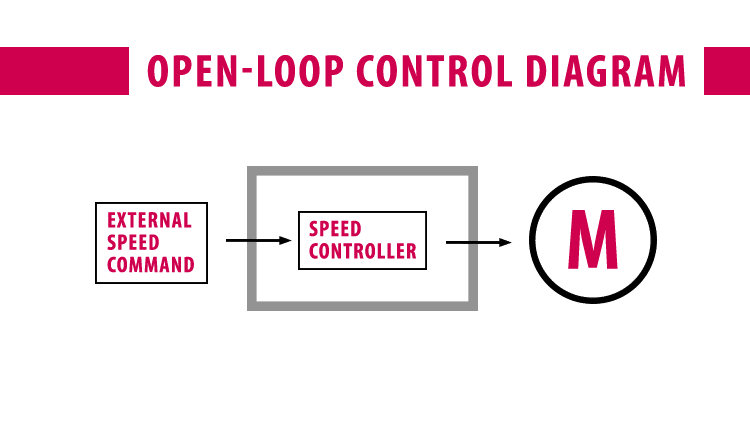

An Introduction to Feedback Devices for VFD and Servo Applications

This article will be expanding on the different types of feedback devices in VFD (Variable Frequency Drives) and Servo applications, as well as some of the typical applications in which they are utilized.

What's the Difference Between a Servo Cable and Motor Cable?

Electrical engineers often work with motor cables and servo cables, which both supply motors with electrical energy and have a nominal voltage of 600/1,000V. But what exactly are the differences between the two cables?

Omron Helps Life Sciences Company Upgrade Prototype with Cutting-edge Technology and Cut Costs by 30% With Solution Using NX-I/O

Omron gave preference to EtherCAT over DeviceNet because the latter is a slower CAN-based protocol designed for sensors and it uses screw-type connections that can be difficult to install and maintain.

Binders M12A Male & Female Cable Connector with Plastic Threaded Ring

The Polyamide material exhibits very good chemical resistance and is especially oil resistant. A reduced lead-time and cost over our standard metal threaded nut is always good for buyers and planners.

Top 5 Reasons to Use Flat Cables Instead of Round

Flat Cables have many technical and performance enhancing advantages over round cables, so Cicoil has released a New Video to clearly illustrate "The Top 5 Reasons to Use Flat Cable in your Design"

How to Tell Category Data Cables Apart

The category positively correlates with the data speed. I.E. the higher the category, the higher the possible frequency and the higher the frequency, the higher the possible data rate.

Records 1 to 9 of 9

Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.