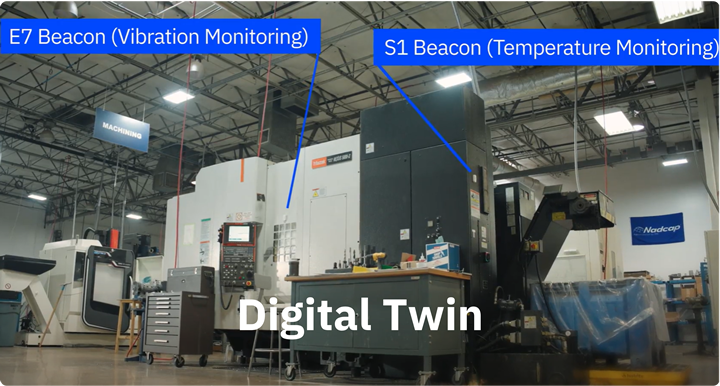

Experience Unprecedented Visibility With AI-Powered Production Monitoring

Barriers to Wider AI Adoption in the Supply Chain Realm

ADLINK's AI Edge Server Successfully Deployed in Smart Manufacturing, Driving AI Innovation and Digital Transformation

The Future of AI in Warehouse Design

The Interplay Between Robotics and Artificial Intelligence in Manufacturing

The AI Imperative: Crafting Your Manufacturing Future

AI Capabilities Your Manufacturing Organization Likely Hasn't Thought About

A Packaging Look-Ahead for 2024 and Beyond

Industrial AI begins: Curse or blessing?

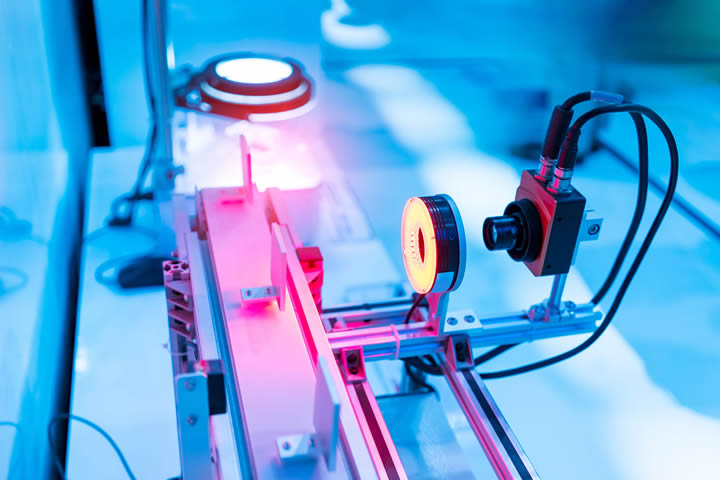

The secret lives of manufacturing defects - How defects pass through the system undetected

Using AI to Fill Blind Spots and Revolutionize Manufacturing Processes

DOOMSDAY CLOCK REMAINS AT 90 SECONDS TO MIDNIGHT

Why Automated Optical Inspection Is a Winner in PCB Quality Control

Manufacturing the future: How plants can harness the power of AI

This 3D printer can watch itself fabricate objects

Records 16 to 30 of 97

First | Previous | Next | Last

Featured Product

.jpg)

.jpg)

.jpg)