7 Emerging Solutions for Reduced Manufacturing Downtime in 2025

Manufacturers hoping to reduce downtime more effectively in 2025 should pay attention to several emerging trends. Here are seven such technologies and strategies for greater uptime this year and beyond.

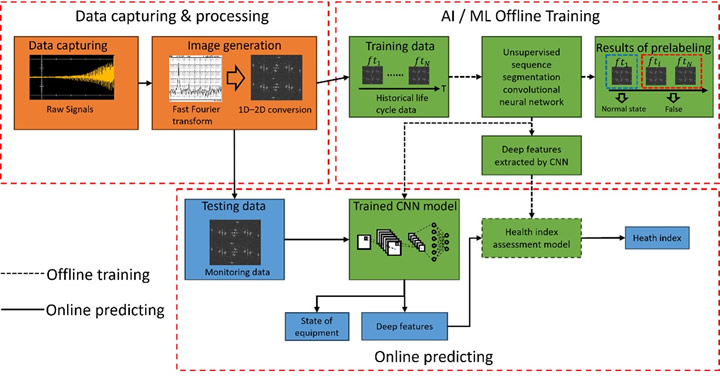

Machine Learning Unlocks Predictive Maintenance for Manufacturer

With an accuracy rate of more than 99%, AI-aided predictive maintenance systems can greatly reduce costs and improve uptime for manufacturers.

Reliable Industrial Robots with AI - Enhancing Fail-Safe Operations with Predictive Maintenance

With industrial robots' hourly operating rate of $2500, the financial impact of their failure can escalate quickly. Thus, it is crucial to avoid such technical disruptions in operations, whether it involves one singular robotic arm or several hundred industrial robots.

Proactive Maintenance: The Key to Reducing Unscheduled Downtime

Thermal imaging, also known as Thermography is a powerful tool for preventative maintenance in manufacturing. It involves using infrared cameras to detect heat patterns and anomalies in equipment

Three Ways AI Improves Maintenance Operations for Manufacturers

AI-driven maintenance decision intelligence tools give teams an unparalleled level of efficiency and insight, automating the integration of varied data sets and surfacing insights across your maintenance operations technology stack.

The Benefits of Predictive Maintenance Capabilities in Energy Management Systems for Industrial Facilities

Future trends in predictive maintenance focus on leveraging AI and machine learning to improve system accuracy and efficiency, and integrating IIoT for enhanced connectivity and data exchange in smart factories.

Beyond Noise: The 5 Benefits of Acoustic and Vibration Analysis

If we know the good behavior of a stationary random vibration, we can analyze and understand the random vibrations of a rotary machine that is wearing down over time and predict its failure.

Minimizing Unplanned Downtime: Strategies for Maximizing Productivity in Your Plant

By leveraging robust downtime tracking and analysis strategies, you can pave the way for preventative measures that detect and address potential defects in equipment promptly to protect production efficiency and safety.

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

The key difference between preventive maintenance and predictive maintenance is that the latter means completing maintenance only when needed, as opposed to scheduled intervals.

ABB survey reveals unplanned downtime costs $103,000 per hour

It emphasizes the importance of effective maintenance strategies and service partnerships. 92% of respondents are interested in how outcome-based maintenance agreements can boost business success

What is Data Analytics?

Data analytics is a powerful tool for manufacturers, which involves applying mathematical techniques to extract valuable insights from data. This can help to improve systems, understand trends, and increase efficiency across various industries.

Predictive Maintenance as a Service: a Game-changer for Manufacturing.

Manufacturing encompasses a diverse and wide array of processes, industries, and raw materials. Yet all manufacturers everywhere share a common enemy: Unplanned Downtime, which harms productivity, asset health, brand reputation & dotted line.

From Downtime to Uptime - the Need for Predictive Maintenance

Manufacturers have long dealt with equipment failures. While they may be inevitable, equipment failures should not cause serious downtime, eat into profits or make manufacturers overspend their budgets.

8 Causes of Lost Productivity in Manufacturing and How Managers Can Address Them in 2022

Addressing lost productivity is particularly critical in today's climate. Despite technological advancements and economic growth, manufacturing productivity has declined since 2010, likely for the first period in American history.

What Continuous Improvement Looks Like in Manufacturing

Manufactures that are able to focus in with laser precision on developing and maintaining a robust continuous improvement process will keep their competitive edge.

Records 1 to 15 of 29

Featured Product

Parvalux by maxon - AC or DC electric motors for conveyor systems?

The material handling industry uses conveyors to ensure that products are distributed effectively, AC or DC motors are chosen depending on the weight it needs to carry and the speed at which it needs to work. Learn which type of conveyor motor might be best for your application and how Parvalux can help you select a geared motor from stock or create a fully custom design.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)