How AIoT technologies drive manufacturing digitalization

In the rapidly evolving digital age, manufacturing is undergoing significant changes. Advanced technologies are reshaping the industry, and manufacturers worldwide are looking for innovative ways to optimize production and improve efficiency. AIoT (Artificial Intelligence of Things) is playing a key role in this transformation, combining AI and IoT to enhance operations, safety, and productivity in factories. Automation.com and Hikvision have jointly released a white paper that explores how AIoT is helping manufacturers work more effectively.

Enhancing production efficiency

AIoT can help drive improvements in production efficiency. Hikvision’s workshop digitalization solutions provide managers with real-time views of production lines. For example, in a cement manufacturing enterprise in China, Hikvision’s radar solution inventories a 250,000-ton aggregate warehouse in just 2 minutes, improving output quality stability by 60%.

Simplifying access and vehicle management

AIoT also simplifies the management of people and vehicle access within factories. Hikvision’s facial recognition system allows workers to enter the building without the need for keycards, making access both quicker and more secure. The system can also be integrated with human resources to record attendance. For vehicles, the yard management system (YMS) uses cameras to monitor entrances, loading docks, and vehicle speeds, making the process more organized and efficient.

Enhancing factory security with AIoT

AIoT also contributes to improved security in factories. Hikvision’s smart security system uses cameras and sensors to monitor the facility. High-point cameras offer a wide view of the area, while thermal cameras can detect abnormal temperatures to prevent fires or equipment failures. This multi-layered approach helps manufacturers respond quickly to potential risks.

Towards a safer, more efficient future in manufacturing

Hikvision’s AIoT technologies support safer and more efficient manufacturing. From advanced security systems to more streamlined production lines, these solutions help manufacturers stay competitive in today’s digital landscape. By adopting AIoT, companies can improve safety, optimize operations, and enhance overall efficiency.

With integrated advanced technologies like AI and IoT—AIoT—manufacturing enterprises can experience high efficiency. Hikvision offers AIoT solutions, transforming safety, efficiency, and plant operations and shaping a new era for manufacturing. For the overall safety of the plant, Hikvision’s smart manufacturing solution ensures centralized, visualized, and networked security management.

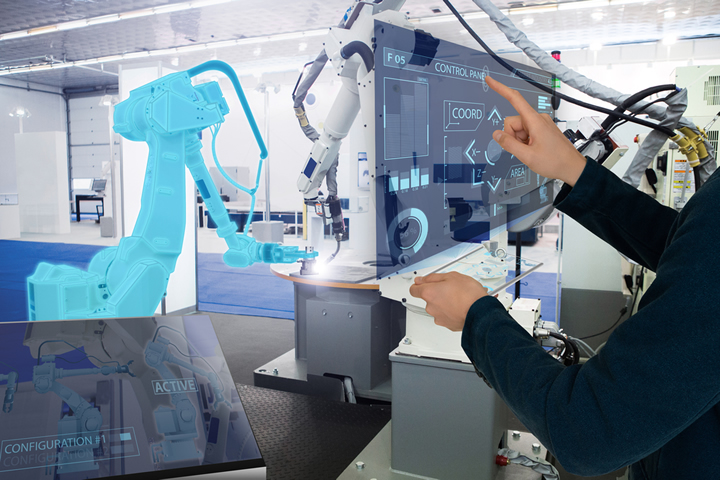

Application Scenario

A company with multiple plants can centrally manage personnel and vehicle access, plant security, video monitoring, and other operations in a command center. Operators in the plant’s monitoring center can use AR for intuitive and efficient video patrols of the plant.

Hikvision’s smart manufacturing solutions have been successfully implemented globally, benefiting users in diverse industries like electronics, chemical processing, automotive, and food processing. With Hikvision, the future of manufacturing safety and efficiency is not just envisioned, it is realized, setting a new industry benchmark for a smarter tomorrow.

About Hikvision India

Hikvision India is the leading video security solution provider. In addition to the security industry, the company extends its reach to Smart Home Products and Solutions, Industrial Automation, and Robotics to achieve its expansion plan. The endeavour is to provide superior pre- sales and post-sales service through collaboration with local distributors and its allied partners.

Driven by the ‘Make- in-India’ vision, the company manufactures a wide range of video security products at its state- of-the- art manufacturing facility near Mumbai. Building on innovation and research and development initiatives, Hikvision India is committed to provide best quality products with agile technical support through its Pan India branches and employees.

For more information, please visit us at www.hikvisionindia.com

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product