Diode Laser on your 3D Printer, Perfect Tool for Makers?

3D printers are amazing for makers everywhere, as they enable easy, cheap, and fast progress on projects. They can’t do everything though, especially if you want a different material from plastic, you’re for the most part out of luck. That’s where CNCs, and laser cutters come into play. They allow you to work with many more materials, like wood, acrylic, metal, and more. Compared to entry level 3d printers, even small CNC routers and laser cutters are quite expensive though. So, what if you could use the existing motion system of your 3d printer and just add laser cutting and CNC functionality? With CNC, that is quite difficult due to the much higher forces that are applied to the tool head. Laser cutting however doesn’t have that issue, so it’s a prime candidate to be retrofitted onto a 3d printer.

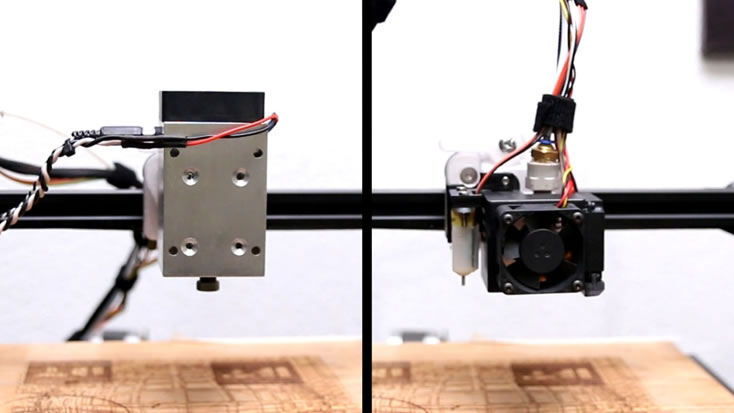

Quickchange system for 10W Endurance Laser on Creality CR-10

How to add a laser to your 3D Printer

Since CO2 lasers are bulky and difficult to dial in, diode lasers are a much better choice. They are quite small and light, so they can be easily either mounted next to the hot end, or instead of it. Most units you can buy come with simple electronics, where you only need to supply power, and if you so desire a PWM signal to modulate the output power. Since you aren’t using the heated bed and hotend while laser cutting, chances are good that your printer’s power supply has enough power, to also feed the laser. The PWM signal for changing the output power can be attached to the part cooling fan output, since you also don’t need that while using the laser, and it is really simple to control that pin using software, without having to modify the printer’s firmware.

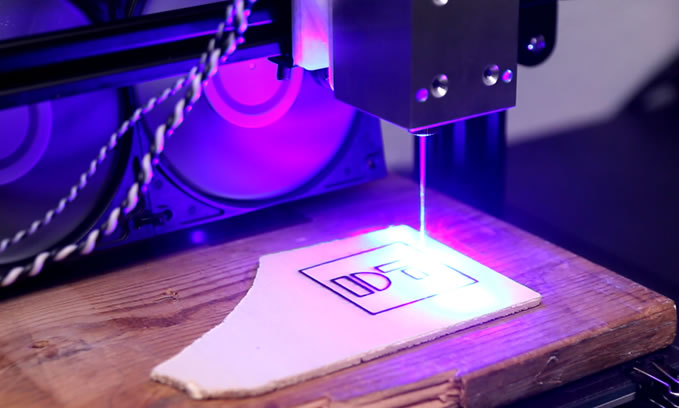

Laser in action, cutting 4mm plywood

The next thing to consider before taking the plunge is, how much laser power you need. If all you want to do is burning pretty pictures onto wood, you can easily get away with a cheap Chinese unit around 0.5W to 2W. They can be had for very cheap and are a good way to get your feet wet with lasers, if your budget is limited or you’re not quite sure if you want to stick with it. If you want to do a bit more tough and also get into cutting things like cardboard, leather, wood, or dark acrylic, you need a bit more power. Most cheap Chinese units will go up as far as 15W advertised power, however you need to keep in mind, that most likely you won’t be getting the full advertised wattage, or at least not continuous. The better option, if you want a powerful diode laser, is to buy from a western company like Endurance Lasers. Their lasers are tested to achieve their rated power and keep close to that power in continuous use. While that is certainly the more expensive option, it is worth keeping in mind that you usually get what you pay for when ordering cheap tools from China.

What can you do with it?

Now that you know a bit more about the types of lasers, let’s take a look at some of the cool things that you can do with them.

Leather phone cases are really popular, but they all look pretty much the same. So how about customizing yours a bit by burning a design on it with the laser. A wallet style case gives you the most area to customize, but this of course also works for a case that just goes on the back of your phone. When taking measurements for how big the design should be, make sure that you also take note of any cutouts, and where they are located, so that you don’t loose an important part of your engraving. Other than that, you can leave your imagination free range. Anything is possible, from logos, to your favorite quote, or even a simple image. Just keep in mind that depending on what color your leather is, the contrast might not be that strong, so it’s advisable not to go with too complicated of a subject. Depending on what kind and color of leather your case it made out of, the engraved parts might also not be dark, but actually lighter than the surrounding areas. This is because the top layer of the leather is often dyed, the engraving then exposes the original color of the leather underneath.

YouTube video about leather engraving: https://youtu.be/rT1IHkC7E3M?t=579

The finished phone case, fresh off the laser

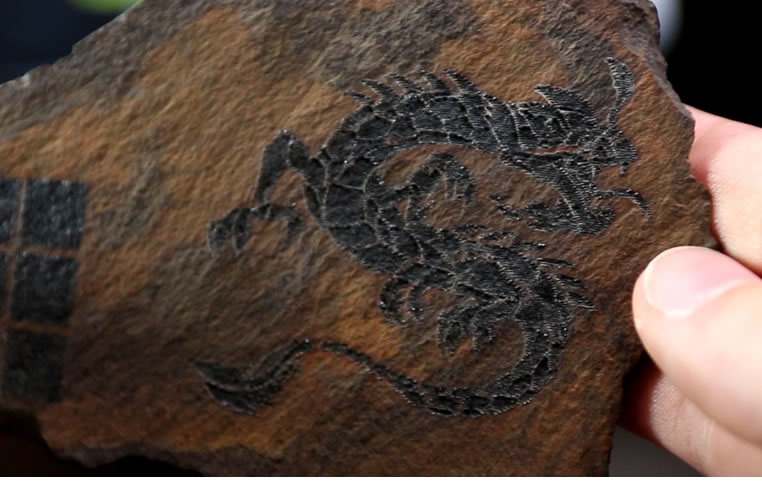

A powerful diode laser isn’t just limited to engraving on organic materials tough. With a laser of sufficient wattage, like for example the 10W version from Endurance, it is possible to engrave on most dark stone, and glass. This opens up a whole new world of possibilities, like for example engraving a design on coasters made from slate stone, customizing bottles for personal gifts, adding your own design to your coffee cup, and many, many more. With these materials you will have to go quite slow and make sure that the laser is properly focused, but with some patience you can create results that look really professional. Be it as gifts, for personal use, or to sell on your Etsy store, not being limited to materials like wood, or leather is quite amazing.

YouTube video about glass engraving: https://youtu.be/CAdhkNOd8lY

YouTube video about stone engraving: https://youtu.be/pwsQYWVGtoA

Dragon engraved on a flat stone with 10W laser

That is not to say that you can’t also make beautiful projects with wood. One nice example would be this chessboard, made from some beautiful white oak, with the layout burned on with a laser. The matching chess pieces were made out of 4mm plywood, which was no problem to cut with a 10W laser. To get the black pieces, the plywood was spray-painted black before cutting out the pieces to speed up the process. Due to the laser cutting, the edges will also be black, so no need to touch up.

YouTube video about the chess board: https://youtu.be/6EOaFTVo-uI

Finished chess board with laser cut figures

So, are there things that you can’t do with a blue diode laser, that would be possible on a CO2 laser? Certainly, engraving on metal for example needs a special paste or spray to work with cheap blue diode laser, but the list of things that you can do is very long and the hit on your wallet will most likely be much smaller as well, leaving you with more to spend on other techniques like CNC cutting, or resin 3D printing. You also have the great benefit of not needing to add an additional machine to your workshop, that would take up valuable space, due to how easy it is to retrofit a diode laser onto a 3d printer or CNC router.

About the author:

David Wieland

I am a tinkerer, hacker, DIYer, and YouTuber. I do everything from 3D printing, to laser engraving, CNC, or even woodworking, as long as it has something to do with making. I also make videos for the Endurance Lasers YouTube channel.

YouTube: https://youtube.com/datulabtech

Instagram: https://www.instagram.com/datulabtech/

Comments (1)

Featured Product