ABB Robotics launches Energy Efficiency Service to help customers save costs and enhance sustainability

• Robotics Energy Efficiency Service cuts costs, enhances sustainability by reducing energy consumption up to 30 percent1 • Tools and analysis provide simple way to measure and optimize robot energy efficiency • Global Energy Efficiency Movement survey2 finds industrial companies see reduced energy costs and enhanced sustainability as key to competitiveness

ABB Robotics has launched an Energy Efficiency Service providing manufacturers with a package of consultation, analysis and tools to increase the energy efficiency of their robots. The service offers up to 30 percent energy savings1, addressing the high energy costs that hinder the competitiveness of 58 percent of surveyed global manufacturers, according to a recent Energy Efficiency Movement report2.

Gauging the energy efficiency of industrial robots has traditionally been a complex task, involving measuring multiple electrical components. It has also been difficult to gauge the impact of factors such as inefficient setup, component sizing, overloading, and application changes that can cause changes in a robot's original performance.

ABB Robotics Energy Efficiency Service will address these challenges by combining ABB's 50 years of industrial robotics experience with a suite of energy measurement tools, providing an easy way to assess and optimize robot energy efficiency.

The suite features three main tools - Standby Energy Optimisation, Program Optimization and Energy Monitoring and Benchmarking.

The Standby Energy Optimisation tool is an external measurement tool that customers can use to assess the real energy consumption of their robot and controller. Data gathered by the tool is used to generate a report with advice on ways to save energy and recommendations for further steps for fine-tuning performance.

The Program Optimization tool analyses a robot's operating program to highlight areas where improvements can be made to save energy. Using back up data from the robot, the tool identifies measures such as adjusting the robot's programmed speed or motion paths that can improve performance and reduce energy.

The Energy Monitoring and Benchmarking tool enables continuous monitoring of robot energy consumption and comparison. Data on energy consumption is made available, together with recommendations for improving performance and comparisons with robots in similar applications.

The service can also provide an analysis on the impact of upgrading to new generation technologies offering energy saving features. ABB's next generation OmniCore robot controller, for example, offers best-in-class motion control, as well as 20 percent energy saving through features including power re-generation technology and brake energy recovery.

The Energy Efficiency Service is the latest development in ABB's strategy to help businesses to transform their sustainability by using automation to optimize processes and minimize waste.

ABB Robotics & Discrete Automation as one of the world's leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics - become more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

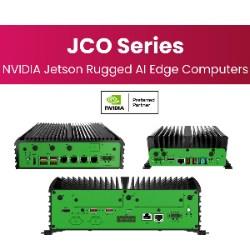

Featured Product