Booth #1003 - we will be showcasing our new 280 Production Series selective laser melting machine. It features a more robust processing system and is designed for series production including multiple laser optics, a built-in, closed-loop powder handling system ...

Contributed by | SLM Solutions

Tell us about your company.

SLM Solutions produces selective laser melting machines and our North American office is your metal additive manufacturing equipment partner. We take a vested interest in your company’s long-term success with metal AM. As part of our commitment to partner with customers, SLM Solutions North America has an office and development lab in Metro-Detroit to foster collaboration on projects. Partnering with our colleagues in Germany, our local team of North American experts, including service, application, and systems engineers, as well as a Ph.D. metallurgist, provide full installation, maintenance, training and other learning opportunities, allowing us to harness the capabilities and exercise best practices for selective laser melting.

Your company will be exhibiting at RAPID + TCT, what is it that makes this an important event for your company?

Rapid+TCT is important for SLM Solutions because it’s the largest additive show in North America, and as such is the go-to destination for companies at all stages of their additive journey. We have the opportunity to present and discuss our thought leadership that helps companies successfully implement an additive manufacturing strategy and can showcase the advancements of metal additive manufacturing, specifically our technology, selective laser melting as it moves toward production capabilities.

What makes your booth a must visit for RAPID + TCT Attendees?

SLM Solutions’ booth is a must visit at Rapid+TCT because we will be showcasing our new 280 Production Series selective laser melting machine.

.png)

It features a more robust processing system and is designed for series production including multiple laser optics, a built-in, closed-loop powder handling system and a permanent filter module. Additionally, we will be showcasing in-booth demonstrations of Additive.Designer, SLM’s diverse and scalable software solution for easy data preparation of complex components for additive production, as well as in-booth presentations from our engineering experts and industry partners on topics such as process design, security or powder management. And of course we also have some cool new parts to share!

RAPID + TCT has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

SLM Solutions will be presenting in the SME Smart Manufacturing Hub and holding in-booth presentations in our own in-booth amphitheater. The Barnes Group Associates will also be holding mini-trainings at the SLM booth, stay tuned to the SLM website for training and presentation schedules.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

When we walk the floor we like to see what new products are being brought to market across the entire process chain. Post-processing techniques are constantly advancing and it’s exciting to see what kind of next-steps our customers can integrate into their workflows. We all have a common interest in furthering the AM industry and when we can advance the technology, we all win.

Manufacturing is undertaking rapid advancements, be it automation, 3D Technology, machine vision or data. Give us an idea on how your company and product is being utilized now in advanced manufacturing.

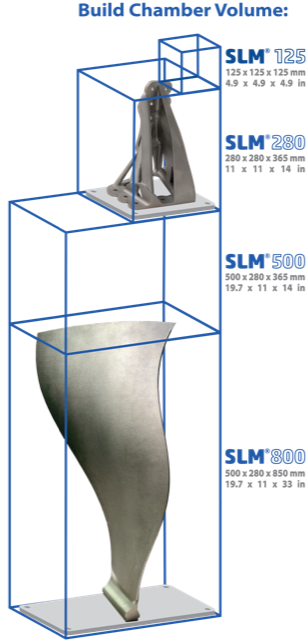

Metal additive manufacturing allows users to biconically design parts to reduce weight and assemblies, while integrating more function, such as internal cooling channels. The technology has been used as part of advanced manufacturing for years now, however systems are moving from the prototype stage to systems capable of series production. The SLM®800, for example, is the revolutionary system from SLM Solutions that creates a “lights out factory” for additive manufacturing. Up to five SLM machines can be hooked up to the SLM®HUB, a fully automated handling station maximizes machine uptime and offers a no-contact powder solution for production processes.

Give us your thoughts on what the future holds for manufacturers and there use of 3D technology.

As more manufacturers adopt 3D technologies into their production and qualification is standardized, the maturation of metal additive processes will reflect these industry needs. Selective laser melting machines pioneered the integration of multiple lasers to increase throughput and automated, closed-loop powder handling to advance the adoption of metal AM for production. We’ll continue to see the entire process chain, from design to 3D process to post-processing techniques integrate with each other and existing manufacturing strategies, making additive another tool in our customers’ production toolbox.

If you would like please provide contact information for a reader to setup a booth demo.

To setup an appointment for a booth demo or visit please contact….

Maria VanHaverbeck, Marketing Specialist

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product