Booth #432327 - We will be showcasing our latest service addition, sheet metal fabrication. We are also going to be highlighting our 3D printing capabilities that have expanded since the last IMTS trade show.

Contributed by | ProtoLabs

Tell us about your company.

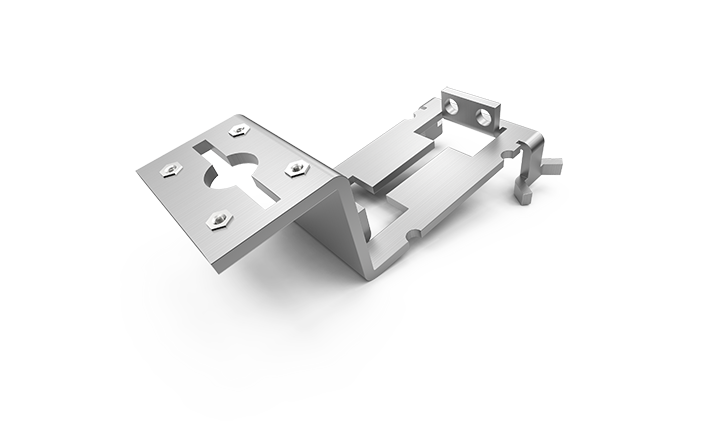

Protolabs is the world's fastest digital manufacturing source for rapid prototyping and on-demand production. The technology-enabled company produces custom parts and assemblies in as fast as 1 day with automated 3D printing, CNC machining, sheet metal fabrication, and injection molding processes. Its digital approach to manufacturing enables accelerated time to market, reduces development and production costs, and minimizes risk throughout the product life cycle. Visit protolabs.com for more information.

Your company will be exhibiting at IMTS, what is it that makes this an important event for your company?

IMTS is a very large trade show that only happens every other year, and since Protolabs is a company that is growing so quickly we are constantly evolving. It is important to introduce ourselves to potential customers, reconnect with existing customers, and continue to educate everyone on how we are able to accelerate product development cycles.

Highlight a 2 or 3 products you will be showcasing at the event?

We will be showcasing our latest service addition, sheet metal fabrication. We are also going to be highlighting our 3D printing capabilities that have expanded since the last IMTS trade show. New technology additions are HP’s Multi Jet Fusion and PolyJet 3D printing.

IMTS has many educational sessions & Demo’s, is your company involved in any of them this year?

Yes, we are involved in three different speaking sessions at IMTS. We have two that are within IMTS and one that is at a co-located show, the Additive Manufacturing Conference.

Presentation 1:

Title: Adopting On-Demand Manufacturing Models to Drive Supply Chain Efficiencies, Minimize Risks and Reduce Costs

When: Mon, Sept 10 from 10 – 10:55 am

Where: Room W192-B

Speaker: Rob Bodor, General Manager of the Americas

Presentation 2:

Title: A Deep Dive into Metal 3D Printing

Presenter: Thomas Davis, Applications Engineer

Date/Time: Tues, Sept 11 @ 11:10 am – 12 pm

Where: Smart Manufacturing Hub (North Hall just outside of Main Concourse)

Presentation 3:

Title: Designing for HP's Multi Jet Fusion: 3D Printing Production and Prototype Parts

Presenters:

- Jon Eric Van Roekel, Process Engineering Manager, 3D Printing, Protolabs

- Nils Hegland, Strategic Partnerships, Protolabs

- John Briden, Sr. R&D Manager, HP, Inc.

Date/Time: Wed., Sept 12 from 9:15 – 9:45 am

Where: McCormick Place, West Hall, Level 3, Skyline Ballroom, W375 C-D

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions you plan on attending?

When I walk the exhibit hall I plan to check out all of the new technologies companies are debuting. It is important to keep up with industry trends not only with what other manufacturers are doing, but also what our customers are doing. It is important to talk to talk to our customers to learn how we can improve and help them even more throughout their product development process.

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

When we book a booth for a show like IMTS we expect to have quite a bit of foot traffic at our booth since this show brings in over 120,000 attendees. We hope to speak to as many attendees as possible in order to hear more about their product development needs and how we can help with any of our four manufacturing services to make their jobs easier. In the end we hope to become every customer’s one-stop-shop from prototyping through production.

A tradeshow of this magnitude is extremely busy and stressful for the staff of exhibiting companies. Any fun things or places your team can suggest in Chicago to help unwind?

One can never go wrong with deep dish pizza! My favorite place is Lou Malnati’s. Another place I always like to stop in at is Three Dots and a Dash which is a fun, underground tiki bar.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product