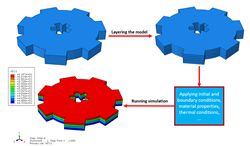

Basics of 3D Printing Simulation: Answering Key Questions

This article provides a comprehensive overview of additive manufacturing simulation, which involves virtually testing and optimizing the 3D printing process.

How Simulation Can Secure Your Robotics Investment

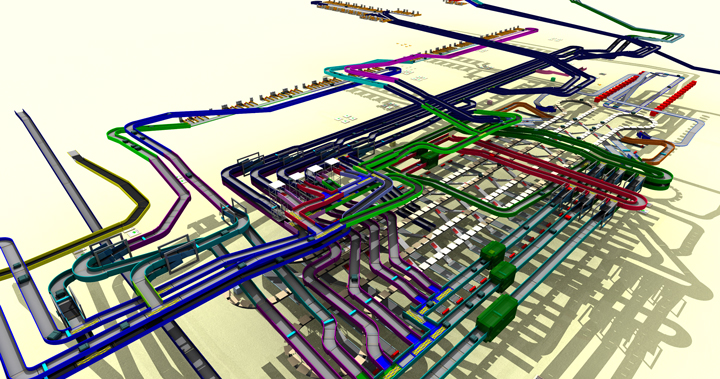

Robotics simulation can be defined as a digital tool used to engineer robotics-based automated production systems. Essentially, robot simulation employs a digital representation to enable dynamic interaction with robot models and machines in a virtual environment.

Why Simulation Is Critical for Driving the Next Era of Manufacturing

As product ideas become more complex, customers are looking for partners with advanced capabilities to help turn concepts into tangible goods reliably, efficiently and quickly. Flex's Paul Baldassari shares how simulation plays a critical role in this process.

Case Study - Reducing Automation System Risk with Simulation and Emulation

Increasing global competition and an awareness of the need to pivot away from on-site commissioning to safer and more cost-effective virtual methods are the main drivers behind a growing interest in industrial analytical simulation.

Simulation Design for Rapid Prototyping

Q&A with Ravi Kunju, Altair: Digital twins offer designers the opportunity to analyze the impact of operational conditions without requiring the production of a prototype until much further along in the manufacturing process when mfg's have a greater certainty of success.

Siemens and Dassault Systèmes Take Top Spots in ABI Research's Manufacturing Simulation Software Competitive Assessment

ABI Research chose these vendors for the assessment due to their simulation capabilities in discrete manufacturing specifically, where software is used to simulate physical processes digitally to optimize engineering, planning, and operations on the factory floor.

Industrial Software for Simulation and Emulation

Companies who do not carry out emulation (or virtual commissioning) can only start controls testing when the real system is at least predominantly assembled, which means they are near ramp and handover, with a large amount of unpredictable testing yet to be started, and probably onsite and under close client scrutiny. Hardly the best of conditions for carrying out the methodical task of analytical verification, debugging and repair.

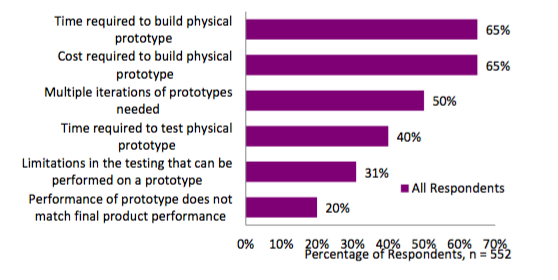

The Value of Virtual Simulation vs Traditional Methods

Overall, the benefits of virtual simulation outweigh traditional design methods on numerous levels, enabling product design timescales to be met more efficiently, and ultimately in a way that helps companies to innovate and grow.

Industry 4.0 Needs a New Generation of 3D Tools

"Digital Factory" solutions - blazing the trail for new manufacturing technologies and production concepts.

Records 1 to 9 of 9

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.