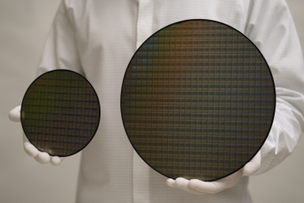

Why Automation, Not Wafer Size, Determines Semiconductor Fab Cycle Time

New 200 mm capacity is often built from scratch or heavily refurbished, making it easier to apply the same automation patterns used in 300 mm fabs. The result is convergence; wafer diameter still affects output per lot, but it no longer indicates the level of automation.

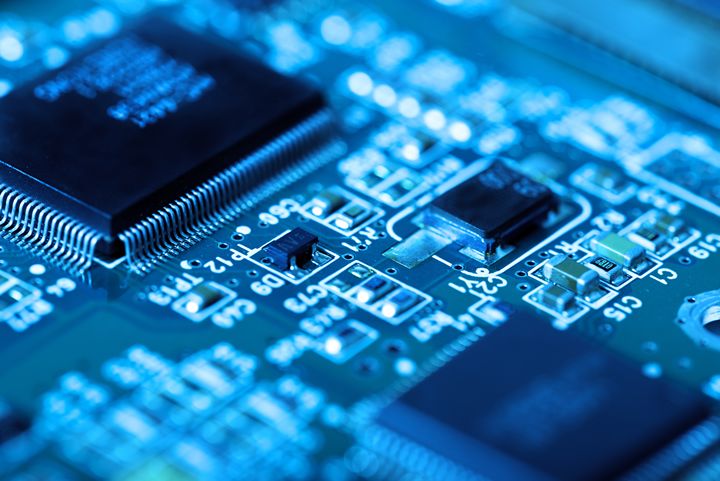

Inspecting Miniaturization: How 2D Laser Profilers Handle Tiny Electronic Components

The miniature size of modern electronic components makes placement, mounting, soldering, and testing of said components rather difficult. Given their size and the overall component density on the PCB, visual inspection is nearly impossible.

Semiconductor Chiplet: New Design Offers Auto Manufacturers Big Benefits

A semiconductor chiplet enables a modular approach to processor construction. In most cases, a chiplet has a dedicated function. These components will be vital as cars become more advanced and autonomous.

Could Energy-Harvesting Technology Power IoT Devices of the Future?

It's particularly challenging to be too reliant on battery-powered IoT devices in industries like manufacturing and logistics. Many factories now have 24/7 operations, meaning there are no feasible downtime periods for recharging.

GF Raises the Bar for Sustainability, Efficiency with Expansion in Singapore

In today's world, a semiconductor fab's performance isn't only measured by wafer output and yields, but also by how efficiently and sustainably it uses natural resources, and how effectively it minimizes the impacts of manufacturing on its neighborhood.

ASE Unveils Plans for the World's First 5G mmWave NR-DC SA Smart Factory

The collaboration will focus on enabling the digital transformation of factory processes that are highly secured and highly reliable through facilitating 5G wireless infrastructure integration, smart heterogeneous equipment integration and OT security system integration.

Records 1 to 6 of 6

Featured Product

Super Air Knife Replaces Blowers & Saves Energy

Super Air Knife reduces compressed air usage & noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across entire length.

https://exair.co/184_523

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.

.jpg)

.jpg)