The Role of PLCs in the Modern Industrial Revolution

New kinds of PLCs are contributing to new approaches to manufacturing and industrial systems. Many people are referring to the more general trend as a 'new industrial revolution' or 'industry 4.0.'

PLC Ladder Logic vs. Everything Else

A programmable Logic Controller is an industrial process control computer which has been "ruggedized" and adapted to control the manufacturing process. Almost all manufacturing processes are modernized and automated by adapting this technology to stay ahead of competition.

Emerson sweetens bid for Rockwell Automation to $29 billion

Greg Roumeliotis for Reuters: The new offer follows Rockwells rejections of Emersons overtures for much of this year.

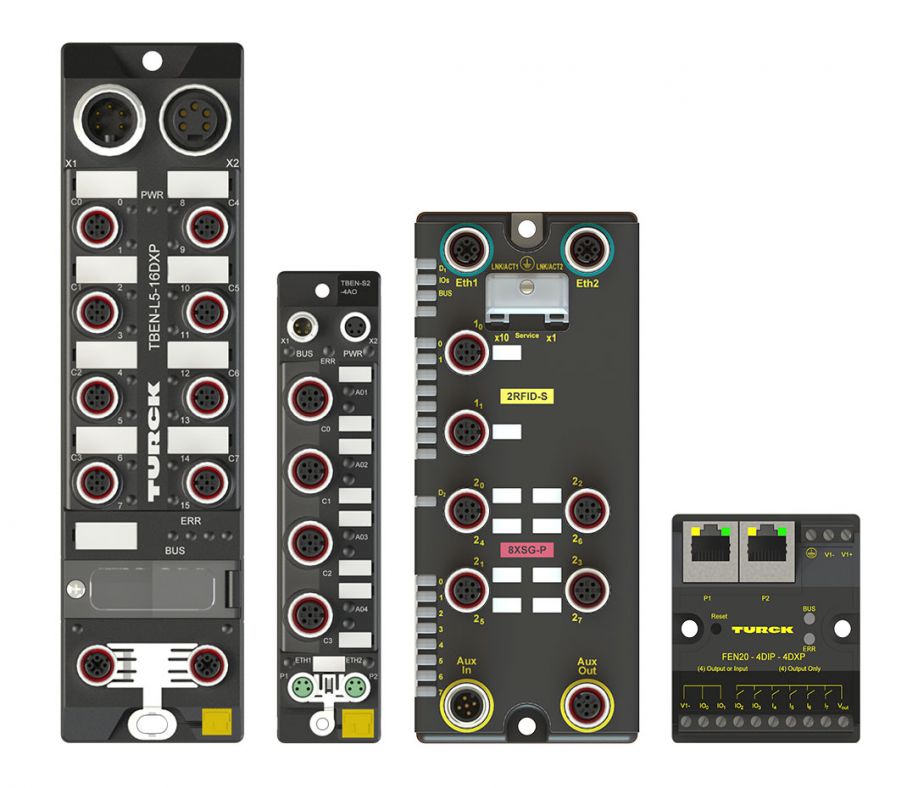

Field Logic Controllers (FLCs) expand control options for industrial environments

FLCs can be used in standalone applications or as a way to expand I/O without adding more I/O points to a PLC.

PLC vs. PAC

PLCs and PACs are similar as they both perform the same essential functions. With modern technology, their differences are becoming more blurred. The most notable difference between PLCs and PACs is their programming interface. PACs are more intricate, using C or C++. PLCs on the other hand, are programmed using ladder logic. These programming differences create distinctions in the architecture and capability between the two computers.

Records 1 to 5 of 5

Featured Product

NVIDIA RTX PRO™ BLACKWELL DESKTOP GPUs N

NVIDIA RTX PRO™ - Built for Professionals - NVIDIA RTX PRO Blackwell Desktop GPUs feature the latest breakthroughs in AI, ray tracing, and neural rendering technology to power the most innovative workflows in design, engineering, and beyond.

Manufacturing and Automation - Featured Company

EMERSON

Emerson's industry-leading portfolio enables us to identify and confront the challenges of an increasingly complex and unpredictable marketplace from a position of strength, driving near- and long-term value as a trusted partner for our customers.