Driving Supply Chain Innovation Through AI and Process Optimization

AI and data analytics are game changers for the manufacturing industry's demand and shop floor agility. My team is currently developing an AI model that identifies irregular demand patterns and updates itself.

Top 4 Complaint Management Challenges and How To Solve Them

Not only is effective complaints management good business practice, complaints management is also a compliance requirement for companies that adhere to ISO standards or are regulated by the FDA.

Tips From an Expert: Creating a Positive Workplace Culture in Manufacturing

60% of business leaders who prioritise performance management say they outperform their competitors. Despite this, 49% of employees say they don't have regular performance conversations with their managers.

6S In Manufacturing

The 6S Lean Management System is a six-step process devised by Toyota Production Systems in the late 1940s. It was used to help them streamline their production with less waste than competitive brands, as well as improving their performance and quality.

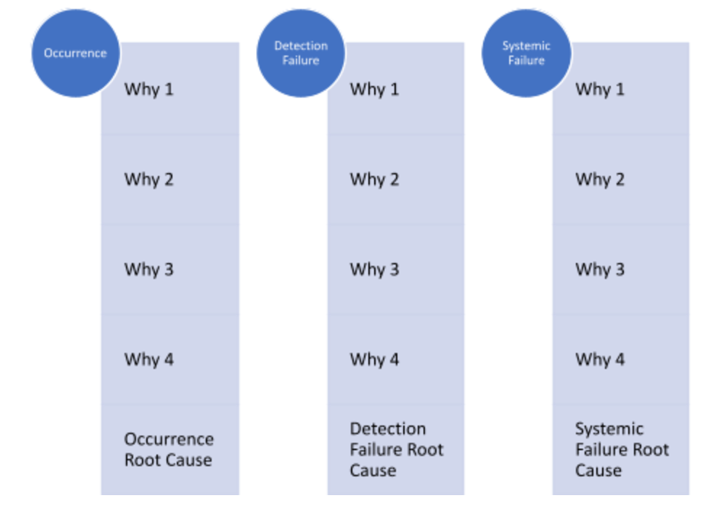

5x5 Why - a Better Way to Resolve Supplier Related Quality Concerns

From my experience, relational governance inevitably creates an atmosphere of loyalty and trust much more easily than one that is adversarial, focusing only on punitive actions when contractual agreements are not met.

The role of Employee Equity Ownership in driving a company's productivity.

In this article, the focus is on giving employees a stake in the company, the objective is to motivate them to do what is best for the shareholders since they are also shareholders.

Dialing Up Productivity with Workstream Collaboration

The coronavirus pandemic is fast-tracking the take-up of "workstream collaboration". This next generation of unified productivity and collaboration tools is designed to make it easier for colleagues to work together from afar.

Purpose, Productivity, and Profitability - The Confluence of Company Sustainability.

The direct influence of a workforce in determining an organization's purpose can be as much, and, sometimes even more of a reason for an individual to enthusiastically and wholeheartedly work at a company as the financial compensation they receive.

Rethinking the Purpose of a Corporation

As someone who has spent his life engaged in driving growth at every level of business operation, it's always been evident to me that to be successful and meaningful to all stakeholders, a corporation needs positive purpose if it hopes to achieve sustainable profitability.

Tips and Tricks for Implementing Automation in Your Manufacturing Plant

IoT and connected devices are making the development process more transparent. The technology also allows plant managers and overseers to accurately review operations, which leads to a more positive direction for everyone.

Lean Execution System (LES)

Together, well-designed technology and people drive solutions. LES is a tool that empowers workers with real-time information to see and solve production problems and create innovation.

Records 1 to 11 of 11

Featured Product

Datanomix Production Monitoring

Datanomix Production Monitoring delivers instant visibility into your shop floor performance. Through real-time alerts, simple machine connectivity, and our kick-ass coaching, you'll catch inefficiencies early, align your team with meaningful metrics, and respond faster to issues before they escalate. The software adapts without operator input and works out of the box with purpose-built Tracks (Efficiency, Delivery, Tooling, and more). Production Monitoring arms you with the data to make more, waste less, and lead with confidence. And while real-time visibility keeps you sharp in the moment, historical insights ensure you're learning from the past to drive ongoing continuous improvement.

Manufacturing and Automation - Featured Company

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today.

How can the FAULHABER MICROMO team help you deliver your next innovation to market first?

Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at www.micromo.com.

.jpg)

.jpg)