Control System Migrations | Managing Scope, Schedule, Budget

Give yourself a pat on the back, you've successfully navigated the tasks of providing procurement specification and selecting a vendor for your control system migration project. In part four of this series, we will be exploring scope, schedule, and budget.

Repurposing and Extending the Life of Aging ATE Systems

ATE stations are specifically engineered to validate the functionality of the units being tested. A substantial investment in testing equipment is necessary, and then… everything changes. Government contracts may not be renewed or could be entirely terminated.

Mitigating Project Risks through Front-End Loading for Control System Migrations

FEL is all about minimizing the risk: The cost risk, the schedule risk, and the scope risk for any capital undertaking. Early in a project, the cost impact of changes is low, but it increases, often drastically, in later stages.

Human Machine Interface (HMI) and its Importance in Industrial Automation

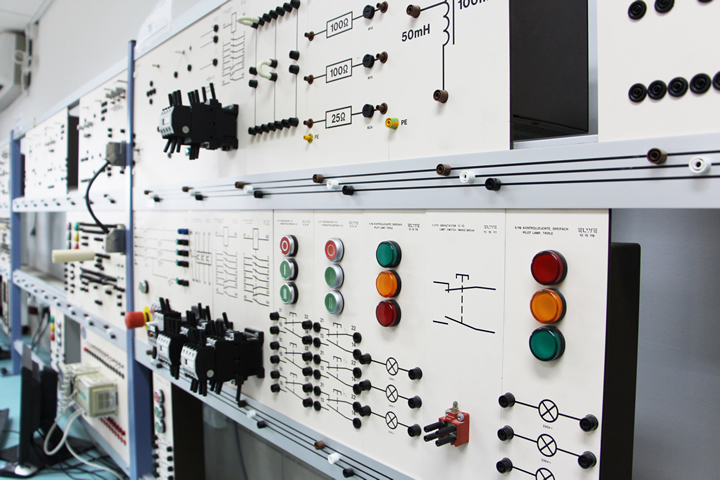

Human Machine Interface; in short "HMI" is the means by which an operator can interact or control the machine or the entire process. It all started with hard wired push buttons and indicator lights on a control panel.

Why Combining Your HMI & PLC Is the Smarter Move

While PLCs control mechanisms, electronics, and other low-level devices, HMIs empower operators with visualization and touch controls. Together, HMIs and PLCs pave the way for efficient and flexible industrial workflows.

Achieving Plant Resiliency - Automation Technologies That Can Make Production More Effective

According to a Deloitte global survey, 94 per cent of executives in industrial companies consider digital transformation a top priority, but only 14 per cent believe their factories are ready for this big change.

Using Biometrics in Industrial Control Systems

The State of Industrial Cybersecurity Report 2018, from the Kaspersky Lab, found that 54 per cent of respondents who had experienced a cyber-attack on their industrial control system (ICS) noticed damage to their products or services. Industrial control systems are critical to business success, so how can we protect them better?

Records 1 to 7 of 7

Featured Product

MRPeasy - ERP for Small Manufacturers That Delivers Results

Always know what you have in stock and what you'll need to fulfill orders. Never forget to order parts on time or fail to notice a late delivery from your vendor. Easily create manufacturing orders and schedule them automatically according to resource availability or delivery deadline. Generate accurate cost and lead time estimates and provide customers with quick quotes. Receive notifications when orders are late or inventory levels reach a critical point. Ensure seamless communication between sales, production, warehousing, procurement, administration, and finance. Integrate with popular accounting, CRM, and e-commerce apps. MRPeasy is an ERP software for small manufacturers that gives you all that and more. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries. Try for free, no credit card needed.