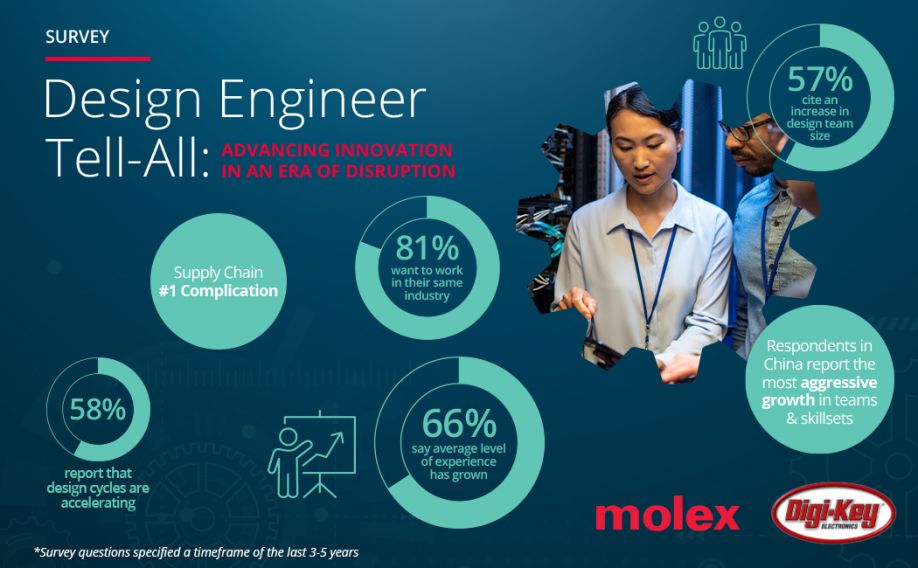

Molex Announces Results of Global Design Engineering Innovations Survey

- 81% of design engineers want to continue working in their current industries while 13% are seeking different experiences

- 58% report that design cycles are accelerating, leading to bigger design teams with more diversified skills and specializations

- 66% cite average level of design engineering experience has grown over the past three-to-five years

- Respondents in China report the most aggressive growth in teams and skillsets

Molex, a global electronics leader and connectivity innovator, today released the findings of a global survey that reveals the aspirations, attitudes and experiences of design engineers as they address ever-increasing product complexity, accelerated design cycles and persistent supply chain constraints. According to 65% of those polled, improvements in design tools, tech innovation and new design methodologies have simplified efforts over the past three-to-five years. Still, a multitude of factors continue to hinder design engineering progress and innovation, led by supply chain issues, higher customer expectations and increased design complexity.

“Today’s design engineers are shaping the future of tomorrow’s most innovative products,” said Aldo Lopez, SVP, president, Datacom & Specialty Solutions, Molex. “This global survey highlights how engineers are diversifying their skills while embracing new design tools and digital technologies to reduce challenges and accelerate the delivery of world-class products.”

Molex and Digi-Key Electronics commissioned Dimensional Research to survey 528 qualified individuals who work as design engineers or manage design engineering teams at manufacturing companies. Survey respondents from the United States, Canada, China, Germany, Japan and the United Kingdom offered insights into the opportunities and obstacles impacting their careers. The summary report, entitled “Design Engineer Tell-All: Advancing Innovation in an Era of Disruption,” offers pragmatic insights into the evolution of design engineering processes, tools and teams to keep pace with shrinking product design cycles, dynamic market demands and persistent supply chain constraints.

Key Findings include:

- 57% cite an increase in design team size and number (52%) over the past five years

- 58% of those polled report design cycles are getting faster, while 43% cite their design organization is more likely to deliver projects ahead of schedule

- 53% embrace both agile and continuous improvement/delivery to enhance efforts

- 88% access “makerspaces,” testing labs or innovation centers for experimentation

Skills and Specializations

According to the survey, 66% of the respondents report their companies’ design teams have more experience on average than they did a few years ago. Additionally, there is an increasing need for diversified skillsets as well as deep expertise in specialized areas. Survey participants believe typical design engineers need to improve skills in the following areas: supply chain management (40%), people and team skills (39%), digital technologies (37%), new design tools (32%), AI or machine learning (28%) as well as user experience and form factor (25%).

The results also reveal that young and female engineers are most excited about incorporating innovative digital technologies into product designs. Millennial engineers expressed the most interest in bolstering their finance knowledge (33%) and AI or machine learning (39%) as compared to their Gen X (14% and 32%, respectively) and baby boomer counterparts (10% and 16%, respectively). Most of those polled (81%) want to continue working in their current industries while 13% are seeking experience in a different industry.

Obstacles and Opportunities

Design engineers take their roles seriously, with 85% reporting they feel responsible for final designs after they’ve been approved. Understanding supply chain risks (34%) tops the list of challenges that create the most difficulties for design engineers, followed by accessing parts or materials (30%) and learning new technologies (24%) as well as balancing manufacturing needs and customer requirements (24%).

A total of 59% of respondents also report having greater flexibility and control over vendor selection. Supply chain reliability (54%), access to engineering support and expertise (43%) and attractive pricing (38%) were ranked as most important in supplier relationships. Lingering supply chain shortages cause engineers to choose alternative materials (59%), minimize production volumes (43%) and exclude planned features (40%) in product designs.

Global View, Regional Focus

Worldwide, design engineers share similar views, yet respondents in China stand out for reporting major increases in both team size (94%) and experience (97%). They also are twice as likely to deliver ahead of schedule than their counterparts (92% vs. 43% globally). In ranking top challenges, respondents from Japan prioritize the need for adequate test plans (31% vs. 21% globally) and join UK participants in addressing the delivery of needed quality (28%/UK and 26%/Japan vs. 20% globally). Overwhelmingly, respondents agree that collaboration skills are just as important as technical expertise, with Germany placing the greatest emphasis on the need to manage increasing levels of collaboration (19% vs. 11% globally).

About Molex

Molex is a global electronics leader committed to making the world a better, more connected place. With a presence in more than 40 countries, Molex enables transformative technology innovation in the automotive, data center, industrial automation, healthcare, 5G, cloud and consumer device industries. Through trusted customer and industry relationships, unrivaled engineering expertise, and product quality and reliability, Molex realizes the infinite potential of Creating Connections for Life. For more information, visit www.molex.com.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product