Creating Energy Resilience in Your Manufacturing Facility

Achieving energy resilience at a manufacturing facility or elsewhere is a two-part process. First, it requires ensuring you have a reliable power supply. Next, an energy-resilient company must have thorough plans for how to respond if a power failure occurs.

Here are some smart ways to build energy resilience in your manufacturing business.

Assess Your Risks

Knowing your risks is the first step to mitigating the issues that could prolong the challenges associated with a power loss. The United States government published a toolkit to help business leaders gauge their risks. A statistic cited in the document indicated storm-related events cause approximately 44% of power outages in the country.

Thus, looking at weather patterns could be a wise place to start. How often does your region experience severe storms? How prepared were you when the last one hit?

Other parts of the government’s toolkit relate to how a lack of electricity would affect your typical operations. Can you deliver goods without power? If an incident also disrupted your internet and phone services, could the company still function? Could your facility suffer temperature- or water-related losses due to control systems that cannot operate without electricity?

Take enough time to determine where your risks exist. From there, consider the most effective mitigation strategies. It’s not always financially feasible to keep your whole factory running during a power outage. However, the next best option is to protect the parts of your operation that pose the most significant threats.

Invest in Appropriate Backup Power Options

Many households in areas of the country that experience significant snowfall quickly learn that standby generators are worthwhile investments. They can provide several days’ worth of power, depending on capacity and fuel availability.

A home generator is not the right choice for an industrial manufacturing plant. However, decision-makers should research the available options based on their current and future needs.

One option launched for manufacturers in the United Kingdom is a resilience-as-a-service offering from Siemens. It covers risk identification and management, plus issue resolution. Getting the advice of a company experienced in energy resilience is an excellent way to ensure you take the optimal path to preventing electricity disruptions and don’t overlook significant issues.

Manufacturing decision-makers can also explore how their backup power choices could positively affect the environment. For example, Microsoft uses diesel-powered generators. It reports that those account for less than 1% of the company’s emissions but intends to phase those out in favor of energy storage and low-carbon fuels. The company wants to eliminate diesel usage by 2030.

Set an Investment Plan

The risk-assessment phase of working towards energy resilience should give you a clearer idea of some of the worst-case scenarios your company could face if proactive changes don’t occur. Use that information to decide how much you’ll invest in energy resilience and how quickly.

While pondering those specifics, don’t forget that your commitment to energy resilience could make current and potential customers view your manufacturing brand as more valuable.

Perhaps your facility is one of the many worldwide that practice lean manufacturing principles. The goal of that approach is to increase real and perceived value for customers. If people know you can keep operating while most companies in a community experience power outages, their trust in your business should rise.

Besides investing in backup power sources and tackling your most prominent energy-related risks, now is an excellent time to verify whether your insurance plan offers power outage protection. Experts say most coverage appears in first-party property policies. However, not all policies have service interruption coverage.

Those that do typically include stipulations, such as that claims do not apply for outages lasting less than a certain period. One of your investment priorities may involve securing a different policy if your current one does not offer enough protection.

Treat Energy Resilience as an Ongoing Goal

Many successful manufacturers progressively purchase more equipment, hire larger workforces, and expand their facilities. They know these decisions directly relate to future success and that it’s necessary to evolve along with the industry. Aim to view your energy resilience plans in the same way.

Identify where weaknesses exist, then develop realistic plans to tackle them. Evaluate your strategies based on current and future needs, and understand that reaching an energy resilience goal is a journey, not an overnight milestone.

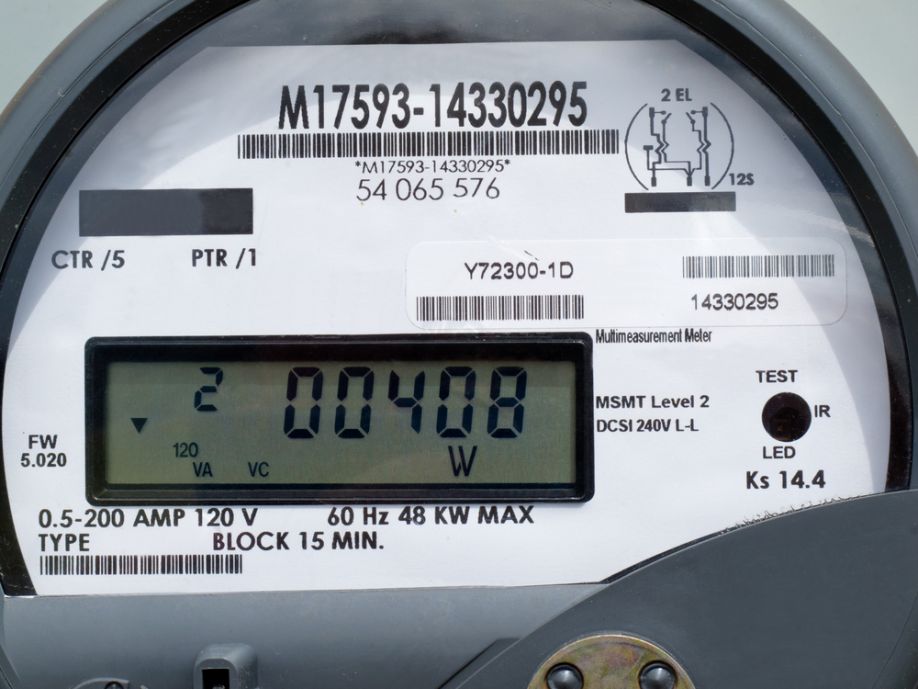

Featured Product