Give yourself a pat on the back, you've successfully navigated the tasks of providing procurement specification and selecting a vendor for your control system migration project. In part four of this series, we will be exploring scope, schedule, and budget.

Control System Migrations | Managing Scope, Schedule, Budget

Control System Migrations | Managing Scope, Schedule, Budget

Tom McGreevy, PE, PMP, CFSE

Give yourself a pat on the back, you’ve successfully navigated the tasks of providing procurement specification and selecting a vendor for your control system migration project. In part four of this series, we will be exploring scope, schedule, and budget. These elements form the “triple constraint” or what is sometimes referred to as the “three-headed monster” of control system migration project management — or any project, for that matter. The success of a migration project depends on balancing these constraints, with trade-offs required to meet objectives while addressing stakeholder needs, industry mandates, and operational realities.

Phased Project Execution and Trade-offs

Ideally, control system migrations follow a phased approach — starting with conceptual and preliminary design, moving through detailed design, and ending in execution. However, phases do not always flow sequentially, and overlapping activities are common, a phenomenon that makes a project more challenging.

At the heart of control system projects lies the negotiation between scope, schedule, and budget. These three variables shape the project from inception to completion. Stakeholders, including project sponsors, operations teams, and users, bring different priorities to the table — requiring alignment to strike the right balance. For example, a project's scope must align with user requirements while staying within budget and schedule constraints.

While many projects have some flexibility for scope, budget and schedule trade-offs, few projects are entirely unconstrained. Rare exceptions exist — such as the rapid construction of the Pentagon during World War II or the development of the atomic bomb — where scope and schedule were paramount, and budget was comparatively unlimited. However, most control system migrations are not afforded a constraint waiver, making the balancing act of scope, schedule, and budget a constant challenge.

The Importance of Schedule and Outage Management

In many control system migration initiatives, the project schedule is non-negotiable. Certain projects — such as those in the energy sector — are driven by government regulations (like Title V permitting) or market demands, forcing strict adherence to timelines. Refinery turnarounds are a prime example: These large-scale maintenance events may only occur every 10 years, and once scheduled, the dates cannot shift. The high cost of shutting down operations for a refinery or chemical plant places immense pressure on teams to execute migrations efficiently within the set outage window.

Outage durations and deadlines are major factors influencing both project scope and budget. Teams must prepare thoroughly to avoid overruns, as missing an outage window could result in costly delays. Planning and execution are equally critical during cutover phases when legacy systems are replaced with new ones, requiring seamless transitions within tight timeframes.

Stakeholder Engagement and Balancing Constraints

A common question when setting priorities is whether quality fits within scope. In control system migrations, quality is considered a given. If the migration is poorly executed, operational issues will surface immediately, posing significant risks to production. Based on this, ensuring quality throughout the process is non-negotiable, even if it means adjusting schedule or budget constraints. Whether the new control system is ultimately a “Chevrolet”, or a “Cadillac” is a scope question, the answer to which depends on user requirements. However, whether a Chevy or a Caddy, the solution must be of high quality.

Scope — V-Model Systems Engineering

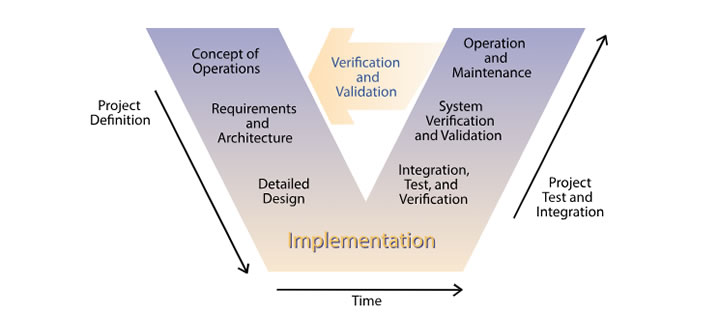

Understanding the V-Model Structure

As the project progresses down the left side of the “V,” each phase deepens the project’s detail, moving through stages such as system architecture, preliminary design, and detailed design. At the bottom of the “V,” the project reaches the development and integration phase, where the designed systems are constructed and configured.

The right side of the “V” begins with the validation and verification stages, where each element developed is thoroughly tested and validated against the original requirements set out in the project’s conceptual phase. This structured approach provides a clear pathway from inception to completion, ensuring that each component of the control system migration aligns with the initial scope and quality expectations. An important element of the “V” is that systems engineering does not end after system commissioning but should continue throughout the life of the asset to ensure upgrades and changes are also managed in a systematic manner.

Benefits of the V-Model in Control System Migrations

One of the unique strengths of the V-Model is its emphasis on early-stage requirements. By investing time in clearly defining the project’s scope and requirements at the outset, teams can better manage expectations, budgets, and timelines. This is particularly valuable in environments where safety and reliability are critical, as any deviation from the intended design could result in costly or even hazardous outcomes.

Scope — Requirements Document

In a control system migration, whether a Basic Process Control System (BPCS) or Safety Instrumented System (SIS), a requirements document addresses the unique demands of replacing outdated and unsupported systems. As technology evolves, older systems eventually become unsupported, are difficult to maintain, lack operational reliability and flexibility, and no longer meet the organization’s needs. Establishing clear, detailed requirements is imperative in ensuring the new control system addresses these challenges effectively.

Key Elements in Requirements Documentation

Physical Environment Requirements: This includes details about the physical assets the control system connects to, such as motors, pumps, compressors, tanks, and valves. Understanding the full scope of the machinery and processes the control system controls is crucial for designing a system that operates safely and effectively.

User Requirements: Operators are on the front lines of system interaction, making user-friendly interfaces critical. The requirements document specifies Human-Machine Interface (HMI) design, alarm management, and process visualization needs, ensuring that operators can navigate the system efficiently and without undue stress.

Maintenance and Troubleshooting Requirements: Maintenance teams need access to troubleshooting tools and systems capable of proactive fault detection. Requirements for system diagnostics, error reporting, and asset management tools (such as those using HART communication protocols) are outlined to streamline ongoing maintenance.

Advanced Control and Optimization: For organizations aiming to optimize quality and profitability, the requirements document includes specifications for advanced applications and optimization tools. These capabilities allow for efficient control of complex processes and help meet business objectives.

Cybersecurity and IT Requirements: IT teams and cybersecurity stakeholders provide input on access control, remote troubleshooting capabilities, and integration with broader IT systems. This is especially important in cases where engineers or maintenance personnel may need secure, remote access to the control system.

Business and Management Requirements: Business leaders often have specific visibility requirements, allowing them to monitor production and other metrics from a management perspective. The requirements document captures these needs, balancing operational transparency with security concerns.

The Systems Engineering V-Model for Requirements Documentation

This phase culminates in a comprehensive set of design deliverables, including finalized drawings and specifications. As the project moves from design into implementation, the V-Model allows teams to check each aspect of the implementation against the original requirements, ensuring that the system meets expectations through validation and verification steps.

Ongoing Maintenance and Adaptation

Scope — Work Breakdown Schedule (WBS)

Developing the Work Breakdown Structure

A comprehensive WBS should be developed early in the control system migration project, ideally before the schedule is finalized. Breaking down the project into smaller components enables teams to estimate durations and resources for each element more accurately. This is especially valuable in complex control system migrations, where precise scheduling is a must-have to minimize operational disruptions.

Owner-Level and Vendor/Contractor-Level WBS

Owner-Level WBS: The project owner (often the client or the entity funding the project) typically defines the first few levels of the WBS. This includes outlining the major phases, primary objectives, and key deliverables. For instance, in government contracts, the owner might specify the first two levels of the WBS, setting the foundational structure of the project without delving into granular details.

Vendor/Contractor-Level WBS: Contractors or vendors are then responsible for developing the WBS beyond the initial levels specified by the owner. They add the finer details needed for execution, filling in tasks, subtasks, and resource assignments to meet the owner’s requirements. This approach empowers contractors to bring their expertise to the project, structuring their work to align with the project goals and optimizing resource allocation.

This dual-level WBS structure allows owners to set clear expectations while giving vendors the flexibility to plan and execute in a way that leverages their strengths. It’s a common practice to help ensure a balanced approach where high-level objectives are set by the owner, and detailed planning is conducted by those executing the work.

Benefits of a Well-Defined WBS

In the context of control system migrations, where tasks may vary in complexity and dependencies, a robust WBS can help mitigate scheduling challenges. Estimating timeframes for smaller tasks is inherently easier than for large, undefined tasks, leading to a more realistic and achievable schedule. Additionally, as the project progresses, the WBS serves as a roadmap, enabling the project team to track progress, adjust resources as needed, and ensure each phase aligns with the defined scope.

For owners and contractors alike, a well-defined WBS not only clarifies project expectations but also enhances the likelihood of completing the migration on time and within budget.

Schedule — Resource-Loaded with Logic

Building the Schedule with Logical Sequencing

Using the WBS, each task in the schedule can be broken down into smaller sections, often organized in a Gantt chart format. The WBS sections align directly with the schedule, allowing for a smooth transition from scope definition to scheduling. As the project progresses from conceptual design (FEL 1) through preliminary (FEL 2) and detailed design stages (FEL 3), the schedule becomes increasingly specific. By the time the project reaches the execute stage, the schedule should be thoroughly developed, reflecting both the scope and WBS in a detailed, logical format.

Resource Loading and Effort Estimation

The resource-loaded schedule allows project managers to see where resources may be constrained or where adjustments might be needed. By integrating resource availability with task dependencies, the team can make informed decisions on scheduling adjustments, such as reallocating personnel or shifting task start dates. This level of planning is imperative in large-scale control system migrations, where resource constraints could lead to significant delays.

The Value of Progressive Detailing

A well-detailed, resource-loaded schedule with logical sequencing is essential for obtaining project funding. Investors and stakeholders need confidence in the project’s timeline and feasibility, and a thoroughly prepared schedule demonstrates both preparedness and reliability. The more specific the schedule at this stage, the better equipped the team will be to manage the project’s complexities during execution.

Schedule — Critical Path

Identifying the Critical Path

A resource-loaded schedule aligns resources with each task, allowing teams to see how resource availability impacts the critical path. By continuously managing to this path, project managers can ensure that resources are allocated to high-priority tasks, keeping the project on track.

Managing the Critical Path

This shifting nature requires a proactive approach to critical path management, with regular reviews to ensure the path remains accurate. Adjustments should be made as necessary to reflect any changes in the sequence or duration of tasks. By monitoring the critical path, teams can quickly adapt to changes and avoid potential delays.

Ultimately, the critical path is the backbone of a control system migration project’s schedule. When managed well, the critical path provides a clear roadmap for prioritizing resources and activities to keep the project on track.

Schedule — Slip

Why Allow for Schedule Slip?

A well-designed schedule with built-in slip is a reflection of common sense and practical risk management. This buffer provides the flexibility needed to adapt to changes without jeopardizing the overall project timeline. It allows project managers to respond to issues effectively, keeping the project on track while managing unforeseen obstacles.

Managing Slip in Schedule Development

In the context of control system migrations, schedule slip is especially important. These projects often involve complex integrations, interdependent systems, and critical operations. Allowing for slip in the schedule ensures that these complexities are managed without excessive risk of delay, helping the project team deliver a successful migration within a reasonable timeframe.

A realistic approach to slip allows for smoother project execution, reducing the impact of setbacks and fostering a more resilient project plan.

Budget — Parametric, Analogous, & Bottom-Up Estimating

Parametric Estimating

Parametric estimates can vary significantly depending on the type of facility and the complexity of the control logic. For instance, while a widget manufacturing plant may have relatively simple I/O points, a chemical processing plant with advanced controls would require a more sophisticated (and thus more costly) system. Although parametric estimates are useful, they should be used cautiously, as variations in project scope or industry standards can impact the accuracy of these estimates.

Unit cost estimating is a similar approach to parametric estimating, where costs are determined based on the cost per unit (e.g., per foot, per ton) of a particular item. This technique is often applied when more specific information about project components is available. In control system migrations, unit cost estimating might apply to components like stainless steel piping or wiring, providing a straightforward calculation for materials or parts with standard unit costs.

Unit cost estimating is particularly useful for elements that have consistent pricing structures, allowing project teams to forecast material costs with a fair degree of accuracy. Like parametric estimating, this approach is more reliable when sufficient historical data exists, enabling comparisons across similar projects or components.

Analogous Estimating

Bottom-Up Estimating

This technique requires a comprehensive understanding of the project’s scope, schedule, and resource requirements, making it best suited for later stages when detailed design and planning are complete. Although time-consuming, bottom-up estimating is highly accurate, as it accounts for specific project needs and is based on actual data from the project’s planning stages.

Each of these budgeting techniques serves a unique purpose at different stages of project development. Parametric and Analogous estimating are effective tools in the early stages when only high-level information is available, while bottom-up estimating provides a more precise calculation as the project reaches maturity. By employing the appropriate technique at each stage, project teams can ensure that budget estimates evolve alongside the project, aligning with the increasing specificity of scope and design.

Budget — Analyzing the Quality of Your Budget

Contingency and Reserve Planning

Assessing Budget Confidence

Moving Forward with an Approved Budget

As the project progresses, maintaining control over scope, schedule, and budget is crucial. Any project that begins with delays or budget overruns is challenging to recover, making it essential to start on solid ground. Proactively addressing risks early increases the chances of successful project completion and mitigates the impact of any adverse events that might arise.

Project Controls — In-House or Third-Party?

In-House Project Controls

Organizations with the necessary skills and resources may choose to manage project controls internally. This approach allows the project manager or other team members to oversee scheduling, estimation, and physical progress. An in-house team can solicit feedback directly from the design, procurement, and construction teams, collating data to update progress against the baseline.

Third-Party Project Controls

Outsourcing project controls can offer a level of sophistication and objectivity that may be challenging to maintain in-house, especially for smaller organizations. These smaller facilities may lack the resources or expertise required for project controls and can benefit significantly from external support.

Risk Management and Decision-Making

Project controls serve as an early warning system, enabling project managers to intervene before small issues become major setbacks. They answer the key questions: Are we ahead or behind schedule? Are we within budget? Are we meeting quality standards? This transparency is invaluable in ensuring that the project stays aligned with organizational goals.

Project Controls in Procurement and Vendor Management

In larger companies, project controls are often standardized across departments, ensuring consistency in execution. Smaller organizations, however, may need to assess whether outsourcing these skills can provide the necessary structure to keep projects on track.

Regardless of the approach, project controls are indispensable for managing scope, schedule, and budget in control system migrations, providing the transparency needed to ensure a successful outcome.

The Takeaway

Moving Forward with Confidence

Be sure to keep an eye out for the fifth installment in our control system migrations series, where we will explore best practices when planning and implementing training after a system migration.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product