Artificial intelligence (AI) is gaining favor as a solution for quality problems, but many manufacturers struggle with the perceived cost and complexity of implementing new technology.

AI for End-to-End Quality

Ed Goffin, Marketing Manager | Pleora

Manufacturers of all sizes struggle with the cost of poor product quality, whether that translates into slower production, decreased profits, or unnecessary waste. Over the long term, poor quality can do irreversible damage to brand reputation. In the food and beverage market, 20 percent of consumers say they will not purchase from a brand following a product recall.

Artificial intelligence (AI) is gaining favor as a solution for quality problems, but many manufacturers struggle with the perceived cost and complexity of implementing new technology. However, new development tools and edge processing significantly simplifies AI deployment for both automated and manual inspection tasks.

The Difference between Machine Vision and AI

Machine vision revolutionized the factory floor, and continues to excel in a wide range of inspection applications. To achieve accurate results, machine vision relies on a programmer’s ability to continuously train a system.

Machine vision rules-based algorithms excel when there is consistency, whether that’s types of defects or material being inspected. If parameters change, the algorithm needs to be manually updated. Rules-based programming struggles when inspecting variable surfaces, such as glass, metal, or textured material.

AI removes some of the hard-coded limitations of traditional programming so inspection systems can be more versatile. This is especially valuable when manufacturing short-run or customized products with different packaging and grading requirements. Another key area for AI is the ability to decrease false-positives and false-negatives generated by rules-based inspection that require costly and time-consuming secondary review.

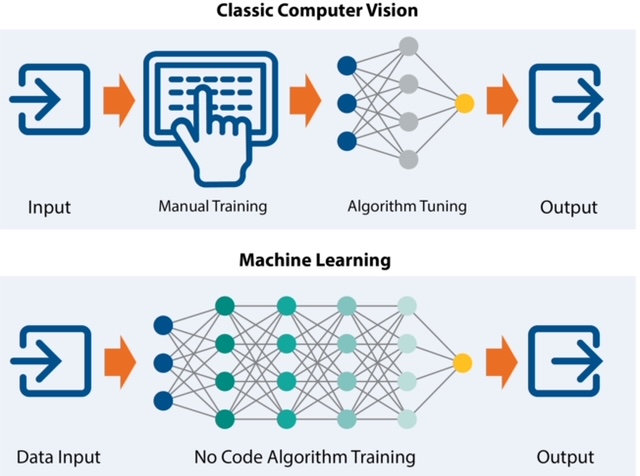

Broadly defined, AI is a machine solving a problem in an intelligent way. Machine learning is a branch of AI where computers are provided with a set of data to learn how to solve a specific problem. Instead of recoding a hard-wired algorithm, the AI system uses good and bad images to retrain itself. It’s important to note that humans are still involved; we need to provide the initial data so that the AI algorithm can learn from that data.

Deep learning then expands machine learning methods to powerful neural networks that are inspired by the way our brains function. With training and labelling, a user teaches the system how to make a decision based on good or bad outcomes. The neural network then can analyze the data and make its own decision.

Classic computer vision requires human input and algorithm fine-tuning to meet different requirements. In comparison, “no code” AI software training packages simplify algorithm development and deployment of more flexible, adaptable inspection capabilities.

“No Code” Algorithms and Edge Processing

For most manufacturers evaluating AI, their key concerns focus on perceived cost and complexity.

There is a misconception that AI algorithm development is complicated, with added costs to bring on new staff or external expertise. “No code” development platforms mean anyone can develop, train, and test an AI algorithm in a few hours. Advanced users can leverage these platforms to mix AI and machine vision algorithms, or customize widely available open source models. In addition, plug-ins for common inspection tasks are easily trained on a user’s unique data to build a custom algorithm.

From a hardware perspective, the power, performance, and cost improvements of embedded technologies make it much easier to add advanced capabilities to inspection applications.

In a retrofit upgrade, edge processing solutions intercept the existing video feed and apply an AI skill. In these applications, high-performance and low-power edge platforms allow manufacturers to add advanced AI inspection skills without disrupting infrastructure and processes. In manual inspection, new edge processing-based systems let human operators leverage AI capabilities to automate processes and help inform decisions.

Edge processing is also changing where decision-making can happen. Traditional machine vision systems rely on networked devices sending data to centralized processing. Embedded vision takes centralized processing power and places it at points where local decisions need to be made. For complex robotics and Industrial Internet of Things (IIoT) systems applications, the combination of small form factor smart embedded sensors and AI enable automated decision-making at different points in a networked system.

Hybrid AI and Inline Inspection

Hybrid AI merges the best of rules-based machine vision with more flexible AI capabilities to help improve accuracy in existing systems, without adding deployment complexities and infrastructure costs.

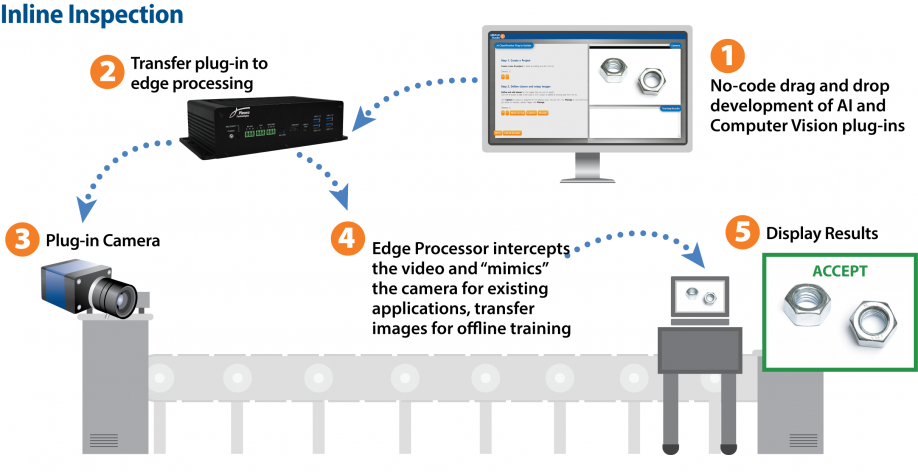

Leveraging embedding processing and a hybrid architecture, AI can be deployed alongside existing traditional machine vision inspection systems. In this deployment strategy, the embedded device acts as an intermediate device between the camera and host PC.

The embedded device “mimics” the camera for existing applications and automatically acquires the images and applies the AI algorithm on top of the camera feed. Processed data is then sent over GigE Vision to the inspection application, which receives it as if it were still connected directly to the camera. This allows the re-use of existing cameras, controllers and end-user applications. The embedded device can be programmed to save incoming images for continuous offline training to improve inspection results.

Hybrid AI is well-suited for manufacturers already invested in machine vision quality inspection. Layering AI capabilities on top of existing machine vision processes reduces false-positives, where even a few percentage points of improvement significantly reduces product waste, lowers costs related to secondary screenings, and increases production uptime. AI is also advantageous for custom ‘short-run’ inspection requirements, where products have different threshold requirements.

The combination of new edge processing technologies and hybrid AI enables a more evolutionary deployment of advanced inspection alongside existing machine vision infrastructure and end-user processes.

AI and Manual Inspection

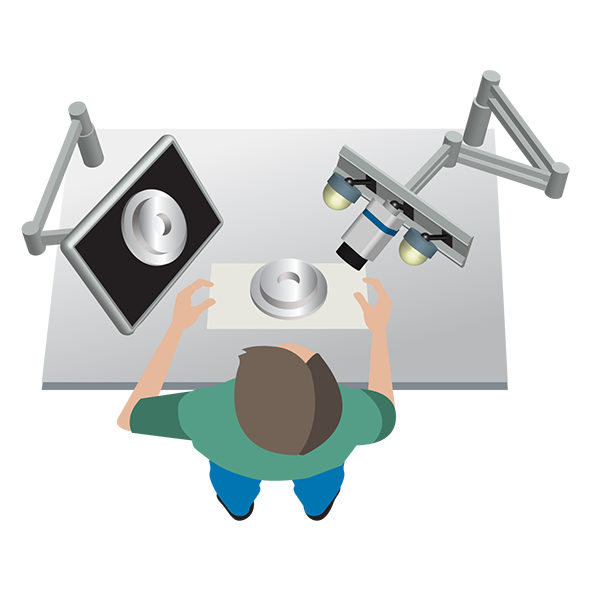

An emerging area for AI is automating or adding decision-support for manual inspection, where manufacturers report errors rates as high as 30 percent. Humans are well-suited for inspection tasks, but when we get tired or distracted AI is a powerful tool to help alert us on issues and guide our decisions. Automating manual inspection speeds inspection rates, improves end-to-end product quality, and provides more qualitative product evaluation to ensure manufacturing processes are repeatable and traceable.

In many manufacturing markets, there are specific inspection tasks are not easily automated or still rely on a human’s unique expertise and judgement. Here, AI is a powerful decision-support tool. Labelling errors, such as placing the wrong label on the product or incorrect positioning, affects the brand on the store shelves. Image compare capabilities makes errors obvious to human operators by comparing products to a “golden master” on the visual display, with flash mode instantly identifying differences and assisted review highlighting potential deviations that require further inspection. Counting and measuring objects is equally time-consuming. Vision systems can help automate this process with features to detect objects and edges for different products.

Primarily, adding vision system based decision-support helps ensure consistency. This can help a tired operator at the end of a shift, an new employee who is unsure what makes a product “good” or “bad”, or simply speed the inspection process. Adding image save capabilities, the system can also be used for traceability systems including inventory and shipment management and batch tracking.

The combination of easy-to-program AI algorithms and edge processing enables turnkey inspection system to automate manual inspection

AI Doesn’t need to be Complex

AI is a tool that manufacturers can use to solve costly, time-consuming, and brand-damaging mistakes. With simplified training and new edge processing technologies, it is relatively straightforward to add AI to existing inspection applications or start automating manual tasks.

About Ed Goffin

Ed Goffin (edg.goffin@pleora.com) is marketing manager with Pleora. Pleora’s AI solutions, help manufacturers reduce errors that result in poor product quality, maintain brand standards, inspect challenging materials, and automate error-prone human inspection. Learn more at pleora.com.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product