Infineon invests S$105 million in Smart Factory

Grocery 4.0: Ocado reshapes retail with robotics and automation

Researchers fire 3-D printed ammo out of a 3-D printed grenade launcher

The optimist's guide to the robot apocalypse

Ford is trying 3D printing for car parts

3D Printing Is Already Starting To Threaten The Traditional Spare Parts Supply Chain

Designing for the digital world

Japan worker shortage has only one winner so far: robots

A 10K tiny house 3D-printed in 24 hours

BeeHex Raises $1 Million For Fresh Food Robots

How Industry 4.0 and BIM are Shaping the Future of the Construction Environment

Dubai company ready to 3D print your house, says 19-year-old founder

Ericsson and China Mobile jointly demo the 5G-enabled Smart Factory at MWC 2017

3D Printing: Should You Go Open Source?

Race For 3D Printing Capacity Could Revive M&A

Records 871 to 885 of 1150

First | Previous | Next | Last

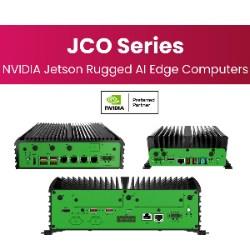

Featured Product