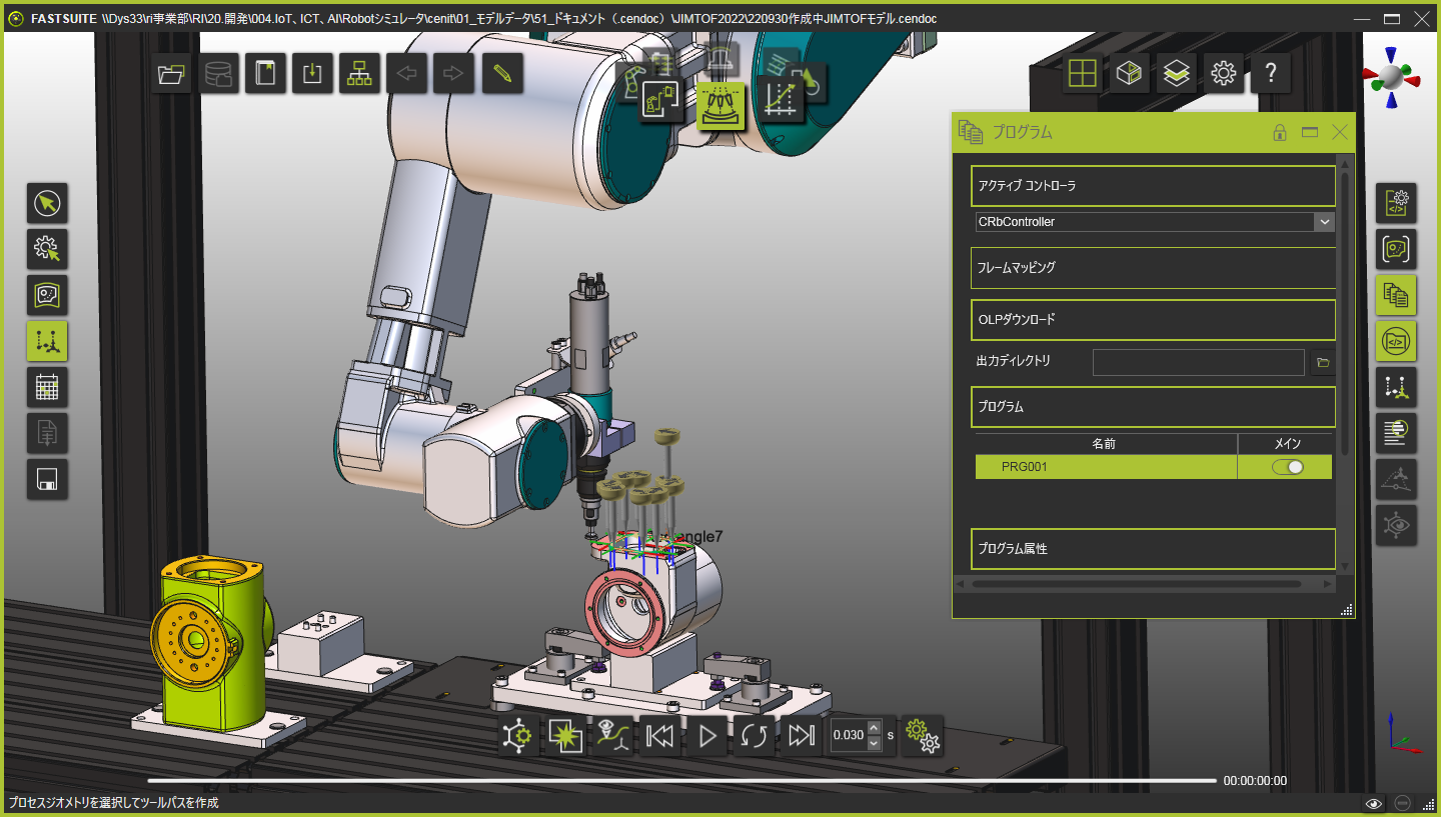

Japanese Robot Manufacturer relies on Digital Twin by CENIT

FASTSUITE E2 technology provides powerful foundation for digital twinning and offline programming at Sugino Machine

A Turn Toward Manufacturing Perfection with CNC Digital Twins

Manufacturers with a digital twin of a prototype can be tested across multiple simulations or designs to reduce the number of physical iterations needed before production or they can be used to analyze product performance.

3 Ways Manufacturers Are Using Digital Twins to Improve Operations

The reality is that ROI that can be delivered when utilizing digital twins to their full potential is game-changing for manufacturers looking to innovate in the wake of a global pandemic.

Determining if a Digital Twin is right for your Manufacturing Operation

Q&A with Chris Nicholson, CEO of Pathmind. A digital twin is at once capable of simulating things that have never happened before, as well as mirroring a real, underlying physical reality and monitoring its performance.

6 AI Driven Ideas to boost Asset Performance Management

Asset Performance Management software must evolve into knowledge hubs that not only deal with monitoring, but also gathering data from other dependent systems to provide much deeper insights and greater control.

Applications of Digital Twins Technology in Diverse Industries

Organizations are implementing digital twins to get better perceptions regarding product performance, user experience, and to make better strategic decisions based on the visions provided by the digital twins.

Digital Twin and Digital Thread: The Innovative Way to Track Product Life Cycles

The interesting thing about modern products is that smart technology can enhance them. That makes them traceable throughout their life cycle, and technologies such as cloud platforms enable the products to be tracked during their life journey.

Building a Digital Twin

The increasing availability and affordability of technologies such as Internet of Things (IoT) enabled devices, data interpretation software and bandwidth mean that more manufacturers can use digital twins to improve their processes.

Records 16 to 23 of 23

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

.jpg)