Automation in the food industry: How smart palletizing holds the key

You simply can't cut corners when it comes to operating in a clean and controlled environment in the food industry. In response to these challenges, automation is increasingly being adopted within the industry. Let's explore how it makes a difference.

Writing it Right: How to Draft a Compliant Food Safety Plan

Several decades ago, food safety management programs were generally reserved for the very largest food manufacturers. Many recognized just how far news of a recall can spread and how extensive the brand damage could be.

Frozen Food Manufacturer Raises Efficiency by 400%

Frozen Garden produces its own healthy food products as well as white-label goods for other small brands. To effectively scale up, founder Allyson Straka decided to implement an MRP system.

One Sweet Machine

From candy to coffee beans, AD Process Equipment's confectionery equipment applies coatings that make food taste better. NORD DRIVESYSTEMS helps them do so more efficiently.

How to Mitigate Supply Chain Risk in the Food & Beverage Industry

Transparency, sustainability, waste reduction and food safety are all significant concerns in need of addressing if food manufacturers want to stay relevant, competitive and optimally profitable, and relying on old strategies is no longer a viable option.

How will the Food Manufacturing industry bounce back in 2021?

Read this article to get insight into the ways food manufacturers can take to rise and shine by putting their business firmly on the road to recovery in 2021

Why food packagers need to trust AI - It is time for food packagers to embrace smart technologies

A survey by McKinsey states that the adoption of automated technologies in the food and beverage industry is relatively slow compared to other sectors, with only 48 per cent of manufacturers considering themselves ready for Industry 4.0.

Traceability in the Food and Beverage Supply Chain

Manufacturing is beset by major challenges that are made worse by hyper shifts in supply and demand. Three main areas that are persistently an issue for Manufacturers are quality and safety issues, waste and underperforming assets, and high environmental impact.

How Does Electropolishing Surfaces Keep Food Safe?

Trouble often comes from the surfaces that warehouses, processing plants and other facilities use. Without the right surface material, bacteria can collect even with the right practices in place - raising the risk of food contamination.

Production line flexibility - How to use modularization for food production increase

According to an industry survey, the majority of food manufacturing companies are expecting to increase production. However, the same study suggested automation does not offer enough flexibility to fulfil an increase in production.

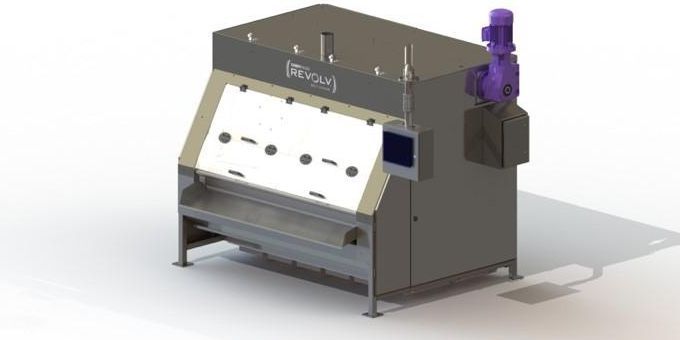

Ensure the Quality of Food through innovative Sieving solutions

Foodborne illness is the global threat to the world. Associations and government bodies have put up strict guidelines to follow in the processing line. Therefore, manufacturers are bound to use hygienic food processing equipment to meet the regulations.

AI and Robotics Revolutionizing Brewing

In the late 2010s, breweries began to explore the usage of AI and automation in crafting beer. Considering the rate at which AI technology is taking over production and service sectors across the world, the integration came as no surprise.

How Will Food Manufacturing Adapt to IIoT

The food manufacturing industry stands apart due to its continual reliance on people. No matter how much automation exists in a plant, people still need to oversee things. Employees will not become obsolete with the introduction of IIoT.

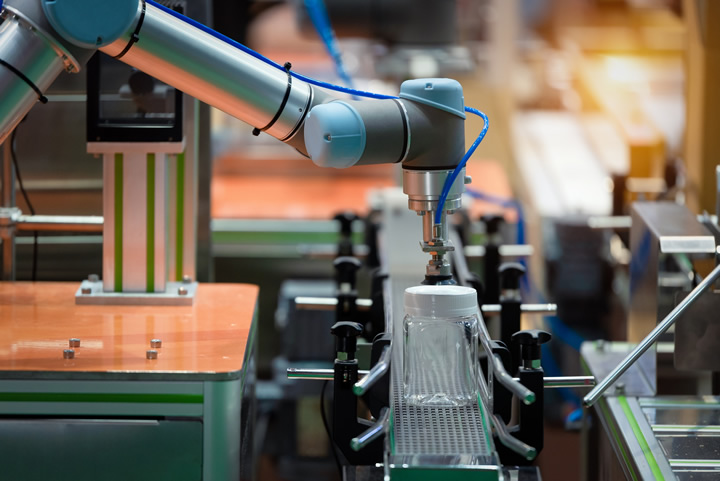

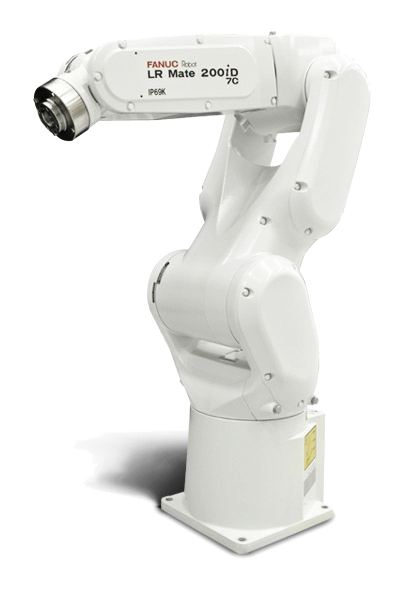

Food and Beverage Survey Shows Increasing Output is a Major Driver for Integrating Robots

Adding robot systems to any stage in food and beverage manufacturing will help to increase throughput. Robots work consistently, around-the-clock allowing for dependable production rates. The latest innovations increase production flexibility and decrease changeover time.

The Internet of Things in Restaurants

The future of IoT in the very competitive food service space relies on the innovations of applications which provide clear ROI or have a strong business case. It is a pennies business and each application will need to stand on its own.

Records 1 to 15 of 16

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Manufacturing and Automation - Featured Company

EXAIR

EXAIR intelligent compressed air® products solve problems in industrial plants while reducing compressed air consumption and increasing safety for personnel. We have the largest variety of sizes, materials and performance characteristics in order to provide the best solution for your processes and problems.

Our products are commonly used to conserve air, cool processes or parts, convey material, clean surfaces or coat surfaces. EXAIR's 15 extensive product lines include air knives, air wipes, air nozzles and jets, atomizing nozzles, static eliminators, cold gun air coolant systems, air amplifiers, safety air guns, air operated conveyors, industrial housekeeping products, vortex tubes and spot cooling products, cabinet cooler systems, vacuum generators, compressed air optimization products, and associated accessories.

Products meet OSHA standards and are CE and RoHS compliant. Five-year warranty on compressed air products and one-year warranty on accessories and electrically powered products.

.jpg)