Non-Destructive Testing (NDT) methods with Digital Inspection Technologies

How can manufacturers integrate nondestructive testing methods with digital inspection technologies to improve product reliability?

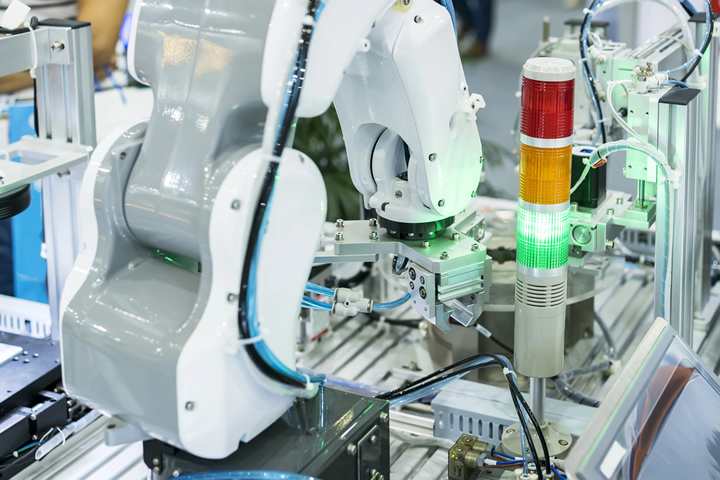

Manufacturers can integrate non-destructive testing (NDT) methods with digital inspection technologies by using advanced sensors, imaging tools, and data analytics to detect defects without damaging the product. By combining NDT with digital tools like AI, machine learning, and real-time monitoring, they can quickly identify issues, track trends, and make more informed decisions. This integration improves accuracy, reduces inspection time, and enhances overall product reliability.

What key steps should companies take to implement digital inspection tools on the production floor while aligning them with existing quality control processes?

To implement digital inspection tools on the production shop floor while aligning with existing quality control processes and procedures, manufacturing companies should take these key steps:

- Assess current processes to identify where digital tools can add value.

- Choose the right technologies that fit production needs and integrate with existing systems.

- Train staff to use new tools effectively and understand how they support quality goals.

- Pilot the solution on a small scale to test performance and gather feedback.

- Adjust workflows as necessary to ensure seamless integration with existing quality control procedures.

- Monitor results and use data insights to improve both inspection and production efficiency continuously.

In what ways does data from digital inspections support predictive maintenance and early defect detection in manufacturing operations?

Data from digital inspections supports predictive maintenance and early defect detection in manufacturing by continuously monitoring equipment and identifying patterns or anomalies that indicate wear or failure. This allows manufacturers to address issues before they lead to breakdowns, reducing unplanned downtime and maintenance costs. The real-time insights also help optimize maintenance schedules and improve overall equipment reliability.

Can you share a real-world example where combining advanced testing methods and digital inspection led to measurable gains in product reliability and production efficiency?

Yes, a strong example comes from an oil and gas pipeline manufacturing plant where we combined advanced non-destructive testing (NDT) methods, such as ultrasonic phased array and digital radiography, with AI-driven digital inspection and welding systems. In fact, our patented AI technology for welding was used to monitor and optimize weld parameters in real-time, ensuring consistent quality and reducing human error. This integration enabled early detection of weld defects, reduced rework by 35%, improved pipeline reliability, and shortened inspection and production cycles by 45%. These improvements led to measurable gains in both product quality and manufacturing efficiency.

What common challenges do organizations face when adopting digital inspection technologies and how can they overcome them to encourage seamless integration?

Manufacturing organizations often face challenges like resistance to change, lack of technical skills, high upfront costs, and integration issues with existing systems when adopting digital inspection technologies. To overcome these, they should invest in employee training, involve stakeholders early to build buy-in, start with pilot programs to demonstrate value, and choose scalable, compatible solutions that align with existing workflows. Clear communication of benefits and ongoing support are also key to encouraging smooth adoption and long-term success.

Looking ahead, what emerging testing methods or digital inspection trends should manufacturers watch to stay ahead in reliability and compliance?

Manufacturers should watch for emerging trends, such as AI-powered visual inspection, digital twins for simulation-based testing, and real-time data analytics from IoT-enabled devices. These technologies improve accuracy, reduce downtime, and ensure compliance by identifying issues earlier and optimizing quality control processes.

Ashok Kumar is a seasoned manufacturing professional with over 22 years of experience driving quality, safety, and process efficiency in industrial production environments. Currently at Welspun Tubular LLC in Little Rock, Arkansas, he plays a key role in advancing operational excellence and compliance across large-scale manufacturing operations. He holds a Bachelor of Technology from Kurukshetra University and multiple certifications in quality control and inspection standards.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product