An Island of Manufacturers: What Does “Made in Britain” Mean for the Economy?

The date of the first new Labour UK government’s budget has been announced, scheduled for 30 October by the new chancellor Rachel Reeves. The Labour election campaign, spearheaded by Reeves and new Prime Minister, Keir Starmer, spoke non-stop of “growth” as the driving force behind a future Labour government.

With a new budget just around the corner, the same thought is on the mind of every UK business – “Will they put their money where their mouth is?”

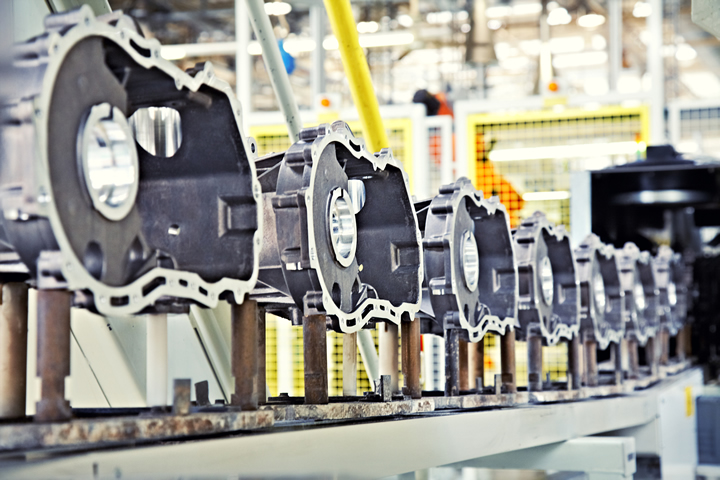

The last budget, devised by the previous Conservative government’s Jeremy Hunt, included £270 million worth of investment in advanced manufacturing, following the initial investment of £4.5bn announced in the Autumn Statement 2023. Both formed part of a plan to support strategic British manufacturing sectors over the next five years – including clean energy, automotive, aerospace and life sciences.

Despite these plans, and reports of manufacturing sector growth for the first time in 20 months, these gains haven’t been seen across the whole country. As recently as this year, green tech trailblazer MyEnergi saw 100 jobs slashed, with over 200,000 manufacturing jobs lost across the UK over the last decade.

A new government could represent a fresh start for British manufacturing, if they increase support for manufacturing businesses and protect the vital jobs they create.

The title “Made in Britain” is a mark of pride for countless British businesses. British manufacturing supports the economy, strengthens our workforce and is a stamp of quality for both the British public and buyers overseas. Following our exit from the European Union and recently revised figures showing the UK entering recession as early as last year, it’s more important than ever that the UK economy becomes increasingly independent.

For further insight into what it means to be a “Made in Britain” business, we spoke to The Heritage Widow Company – a veteran manufacturer of aluminium windows and doors – who has made products in Britain for over 30 years.

Key findings:

- The UK manufacturing industry is worth £518bn.

- UK manufacturing provides 7.3m jobs.

- UK-based manufacturing lowers carbon footprint when compared to international manufacturing, making customers 58% more likely to purchase.

- The label ‘Made in Britain’ has a strong influence in persuading consumers to interact with a business.

- The UK is now the 8th largest manufacturer in the world.

What does ‘Made in Britain’ mean for businesses?

British quality is world-renowned. So much so, that the Barclays Made in Britain report found British-made products hold an important influence over consumers’ decision to buy products – with consumers perceiving them as high-quality, reliable and internationally respected. The ‘Made in Britain’ tag was found to be worth an additional £3.5bn a year to UK exporters.

“We have always made our products in the UK,” says The Heritage Window Company’s Managing Director, Kevin Brown. “It’s important that our consumers know our products are made on British soil for use in British gardens. It holds weight for people knowing that a business is meeting meticulous UK manufacturing laws, contributing to UK employment and staffing local talent.”

British manufacturers don’t only know their products more intimately, they also have a broader knowledge of their consumer's wants and needs.

“Being a Made in Britain business has such a broad range of advantages, from enhanced public image to community presence and quality control,” says Kevin. “You get to know your local and national communities of customers, speak to them in person and oversee the development of products you know will satisfy their needs.

“I cannot overstate how crucial a personal relationship with your customer base is – it informs the products you make and your customers will have peace of mind knowing that your products are made to the UK’s incredibly high manufacturing standards.”

British manufacturing can increase revenue by quickening the turnaround on production and delivery, as well as enabling businesses to offer unrivalled standards of customer care.

“If a customer wants to reach out to a business, the barrier of international manufacturing can have a real effect on their decision to contact,” Kevin warns. “Customers know a UK-based manufacturer is working within their time zone, can oversee manufacturing in person and deliver products within a reasonable timeframe.”

UK manufacturers can also take advantage of the UK’s apprenticeship schemes to gain loyal skilled workers. The UK’s apprenticeship scheme helps manufacturers gain skilled labourers for a lower cost, thanks to the apprenticeship levy. Paid for by large employers with a pay bill over £3m, the money generated funds apprenticeship training for other employers. For SMEs (small to medium-sized enterprises), the government will pay for apprenticeship training, with the business only paying 5% of the wage.

What does ‘Made in Britain’ mean for consumers?

Brits shop with their conscience as much as their wallet – especially in recent years, with more consumers than ever prioritising companies that care about their carbon footprint and support local communities.

The Natural Marketing Institute found that when businesses show they pay attention to their environmental impact, consumers are 58% more likely to buy their products.

Consumers also benefit from improved communication and customer service from manufacturers who produce and ship within the UK. The ability to call customer service within the consumer’s time zone, receive more accurate live tracking updates and pay cheaper delivery costs are a boon to British shoppers.

“Quality control is incredibly important to any manufacturer; you want to be confident that your products are being sent off as intended and delivered with care,” Kevin comments.

“When you manufacture in Britain, you have full oversight of the production and delivery of your product or service – meaning you are less likely to receive complaints or issue refunds. Ultimately, this will save your business countless bellyaches in the long run, helping your business save money and build a positive reputation.”

Why should the public and government care about British manufacturing?

The British manufacturing industry is now the 8th largest in the world, employing 2.6m people and contributing £224bn of output. Now the UK has left the single market, our economy hinges on the manufacturing sector not only surviving but thriving.

The manufacturing industry keeps the UK workforce skilled, meaning businesses don’t have to outsource skilled labour to foreign countries. Further growth in the manufacturing sector will also boost job creation, which is particularly important with UK unemployment leaping to 4.2%.

Britain has a reputation for producing quality goods, and new trade opportunities outside of the single market highlight the importance of our manufacturing reputation. Further support will only strengthen the UK’s international standing, helping to secure new trade relationships.

The effect British manufacturing has on the economy cannot be understated. The recent True Impact April 2024 report by the Oxford Economics and the Manufacturing Technologies Association shows the manufacturing industry is worth £518bn, contributing 7.3m UK jobs. In other words, that’s almost a quarter (23%) of the UK’s GDP.

What’s more, “making things” accounts for 34.5% of all UK goods and service exports and the median wage of manufacturing jobs is 11% above the national average.

British manufacturing isn’t going anywhere soon – a quarter of the UK economy relies on it, as does the livelihood of 7.3 million employees. The new government will be keeping a close eye on the industry as it continues to develop and grow. Recent evidence proves that the value of UK manufacturing is undeniable and further government support will be crucial in helping to lift the UK out of recession.

The Heritage Window Company is a leading manufacturer of traditional-style replacement double windows. Dedicated to providing high-quality, bespoke products, The Heritage Window Company team has over 30 years of experience within the aluminium windows industry. The team can help restore properties to their former glory and add modern beauty to new builds.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product