DSM launches I AM Tomorrow Challenge to drive innovation in 3D printing

Royal DSM, a global science-based company in Nutrition, Health and Sustainable Living recently announced the I AM Tomorrow Challenge, an acceleration program for startups and scaleups focused on data analytics, AI and other advanced software solutions for large-scale 3D printing, also known as additive manufacturing. Launched in collaboration with HighTechXL, Hexagon, and Ultimaker, the challenge offers select companies a spot in a ten-week acceleration program designed to launch or mature their businesses. After the acceleration program, participating startups may be eligible for funding or a partnership with DSM.

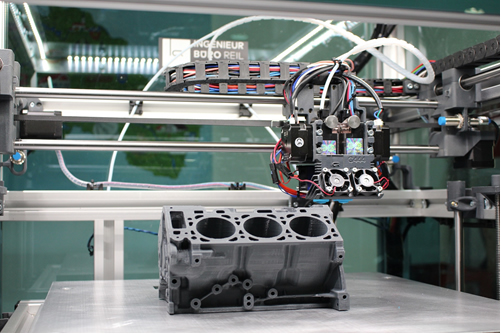

Additive manufacturing is emerging as a more sustainable, transparent, and cost-effective way to manufacture products by reducing waste and minimizing transportation. DSM’s team helped pioneer the additive manufacturing industry more than 25 years ago with its Somos® products. Today, the company actively collaborates and partners with companies across the 3D printing value chain to unlock the full potential of additive manufacturing.

The I AM Tomorrow Challenge aims to stimulate the digital ecosystem that could shape the future of additive manufacturing for decades to come.

“Digitalization will transform the world of manufacturing. By building an ecosystem of partners, we can work together to create tools that support 3D printing design and production, helping our affiliates and customers create innovative new products in a more sustainable way. The I AM Tomorrow Challenge is a step toward a brighter future,†said Hugo da Silva, VP Additive Manufacturing DSM.Â

Â

Unique acceleration program

Startups and scaleups are encouraged to apply to the I AM Tomorrow Challenge through August 8. There is no cost to apply. Ten successful applicants will be invited to participate in the acceleration program, located at HighTechXL’s campus in Eindhoven, as well as in Boston, Massachusetts (USA) which will consist of expert coaching sessions, master classes and exclusive networking opportunities.

During the acceleration program, Hexagon’s Manufacturing Intelligence division will work with DSM and partners to evaluate companies interested in participating and work towards the development of a platform which will provide end-to-end digital solutions for Additive Manufacturing.

For more information on the I AM Tomorrow Challenge, visit: https://iamtomorrowchallenge.com/

Featured Product