NASA Awards $100,000 in 3D-Printing Habitat Competition

Ian O'Neill, Space.com: The first printing segment of NASA's 3D-Printed Habitat Challenge is now complete, and the U.S. space agency has awarded $100,000 to the two winning teams.

Ian O'Neill, Space.com: The first printing segment of NASA's 3D-Printed Habitat Challenge is now complete, and the U.S. space agency has awarded $100,000 to the two winning teams.

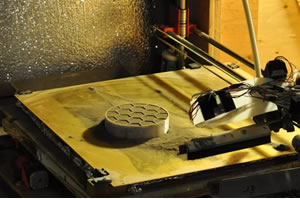

Based on a points system, the "Phase 2: Level 1 Compression Test Competition" winners are Foster + Partners | Branch Technology of Chattanooga, Tennessee (awarded $85,930), and the University of Alaska, Fairbanks (awarded $14,070), NASA officials said in a statement.

Through a partnership with both NASA's Centennial Challenges program and Bradley University in Peoria, Illinois, the 3D-Printed Habitat Challenge aims "to foster the development of technologies to manufacture a habitat using local indigenous materials with, or without, recyclable materials," NASA officials wrote in the statement. Full Article:

Featured Product