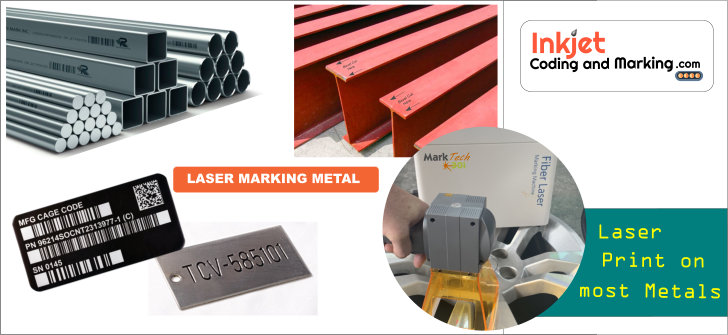

A Metal Laser Engraver is an essential tool for Automotive Industry and anywhere manufacturing requires Permanent Marking for compliance or enduring harsh processes on Metals. Portable Laser Engraver Marker benefits Manufacturing.

Metal Laser Engraver Portability Benefits for Manufacturing

Metal Laser Engraver Portability Benefits for Manufacturing

Contributed by | Inkjet Coding and Marking

The Metal Laser Engraver with Portable Handheld Laser Marker Head benefits Manufacturing to improve workflows for permanent marking of serial numbers, product logos and images of circuits and/or electrical diagrams.

The MarkTech 30i is a Portable Laser Engraver designed with a built-in laser safety shield and embedded Laser Controller with Touchscreen.

Metal Laser Engraver for Manufacturing with Handheld and Portable Laser Marker

Deploy a Handheld Metal Laser Engraver for permanent coding and marking and labeling in the Manufacturing Process.

Portable Metal Laser Engraver offers practical solution for Marking Products too large to move to a workstation

Manufacturing now benefits with an affordable Handheld Laser Engraver option, omitting the need for large or heavy items to be moved to a Laser Workstation Pod or Production Line Automation for Laser Marking.

Redesigned Metal Laser Engraver technology with Portability...Laser Mark / Laser Print on Metals and some plastics.

- Metals

- Plastics and Composites

Portable Laser Engraver for Metal Manufacturing

Laser Marking for Quality Control and Compliance in Metal Manufacturing

The MarkTech 30i is a Handheld Metal Laser Engraver for all manufacturing industries, from the factory floor or warehouse and anywhere Parts and Industrial Products require Marking for Traceability, inventory control and Permanent Identification via Laser Coding and Laser Marking during any stage of manufacturing.

The Metal Laser Engraver is widely used in most manufacturing companies today….however, now Portable Laser Engraver technology solves many challenges where permanent laser marks are required on metal.

Metal Laser Engraver for Metal Tags and QR Code Laser Printer

The Portable Laser Engraver can print anything, without a PC Computer

Touchscreen Control allows users to easily configure the Metal Laser Engraver to print...

- 1D Barcodes

- Laser Print for 2D DataMatrix and 2D QR Codes

- Date and Time

- Text and Serial Numbers

- Counters (Alpha-Numeric - Incrementing/Decrementing)

- Image Logos

- Laser Print Diagrams

How does it work…see the video for Handheld Metal Laser Engraver functionality

Partner with Us for Portable Laser Marking equipment that will improve any Permanent Marking workflow during the Manufacturing Process.

Learn more and shop this product at:

https://inkjetcodingandmarking.com/store/product/marktech-30i-handheld-metal-laser engraver/

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product