A growing number of companies within the sand casting industry are adopting 3D sand printing to produce high quality parts without tooling. The technology to 3D print molds without changing the actual sand casting process itself is a major advancement for the industry.

Massachusetts Metalcaster Established Over a Century Ago Leaps Forward with 3D Mold Printing

Massachusetts Metalcaster Established Over a Century Ago Leaps Forward with 3D Mold Printing

Case Study from | EnvisionTEC, Inc

DW Clark is a multi-alloy metal casting company originally founded in 1902. Through years of steady growth the company today boasts two large sites in Massachusetts, USA. DW Clark provides high quality sand and centrifugal castings and associated services across a broad range of alloys and applications, supplying finished parts up to 2400lb.

The associated services offered include: 3D modeling and casting simulation, finish machining and non-destructive testing. They also support engineers who are considering converting from, or exploring manufacturing alternatives to forgings or weldaments to save cost while maintaining quality.

The business prides itself on the quality of its work and understands that only through satisfied customers can they ensure continued success within the foundry business.

DW Clark is ISO 9001:2015, PED certified, and ITAR registered, in addition to various qualifications for defense part applications.

Why look at 3D printing?

A growing number of companies within the sand casting industry are adopting 3D sand printing to produce high quality parts without tooling. The technology to 3D print molds without changing the actual sand casting process itself is a major advancement for the industry. The use of binder jetting technology allows DW Clark to offer customers a far shorter production time-line of weeks rather than months, bypassing the need for traditional patterns and tooling.

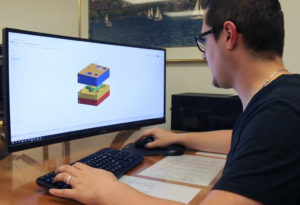

Designs are passed straight from the design department to the Viridis for printing. The technology effectively removes the need to tool a casting die.

Even large items can be cast.

Finished cast items are quickly removed from the sand. Any left over sand is simply recycled for re-use in the Viridis.

Coupled with lead-time reduction, the use of sand printing technology also dramatically reduces the cost of producing parts especially with more complex designs, not requiring or having to store tooling.

Why Viridis from EnvisionTEC?

The Viridis RAM system from EnvisionTEC can be used to 3D print sand molds, mold cores and investment casting patterns for all kinds of foundry applications. The printer is not only has significantly lower up front cost than competitive products, but also uses significantly less sand in the manufacturing process, which in turn means foundries will have to pay out less for materials.

The Viridis RAM system printing.

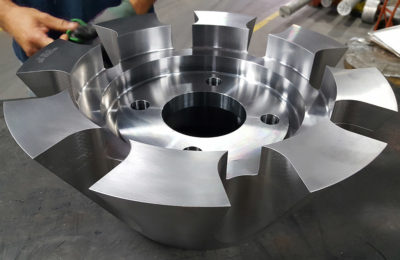

The Viridis allows for the production of complex geometry, for example the impeller above.

The large bed of the Viridis RAM allows for the production of even large and complex molds.

.jpg)

Castings can be poured the same day, and finished much more quickly.

The Viridis machine is extremely versatile and allows for the high speed production of even complex parts.

It prints molds and cores straight from digital models onto a bed of sand one sweeping layer at a time. This it does an impressive print speed of up to 2.5 vertical inches per hour. The size of the printer allows for the production of even large parts, all the way to the RAM 336 (3’ x 3’ x 6’).

The Future?

The Viridis RAM system forms a core offering for DW Clark allowing them to improve not only the quality and complexity of the items they produce but also improve the speed of production for customers.

EnvisionTEC Sand Castings In Just A Few Hours.

The Robotic Additive Manufacturing systems from EnvisionTEC and Viridis3D are the fastest, most flexible robotic 3D printing options in the foundry and 3D printing industries today. Using a patent-pending technology, a proprietary print head attached to an ABB robot arm uses exclusive binder jetting technology to print sand molds, mold cores and investment casting patterns for foundry applications.

The proprietary systems include easy-to-use Viriprint software that uses a CAD file to print a mold and core in just a few hours.

The RAM 123 prints pieces up to 1’ x 2’ x 3’, with a RAM 224 (2’ x 2’ x 4’), RAM 236 (2’ x 3’ x 6’), and RAM 336 (3’ x 3’ x 6’) now available. Viridis3D can also develop custom solutions with this scalable solution.

Foundries will appreciate the speed with which the systems prints — and how fast their operation can be up and running with the new technology. What’s more, the RAM systems use less sand and are substantially less expensive than other sand casting 3D printers on the market today. In fact, the Viridis3D systems use about one-third the cost of competing technologies that build in a box.

This disruptive technology brings a new way of production to foundries — instead of shipping castings around the world, raw materials are shipped and files are simply transmitted to 3D printers in strategic locations. The result is castings are poured the same day, only where you need them.

“Our Mission is to provide the best possible service to our customer in advanced casting technology. The RAM system will continue to be a core part of this.” - Jeff Burek, Vice President, DW Clark

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product