We all know the logic of purchasing: The unit costs for 1 piece are higher than for 10 pieces and these cost per piece more than 100 pieces, and so on. At the same time, the trend is clearly moving in the direction of smaller batch sizes down to a quantity of one.

The Economic Implications of Agile Manufacturing

The Economic Implications of Agile Manufacturing

Rolf Hammerstein | Fastems

As such, manufacturers must be able to produce small batch sizes economically at production costs that are as constant as possible. This article conveys how that goal can be achieved by implementing agile manufacturing systems. In addition, three scenarios are presented that describe the economic effects of agile manufacturing.

The production of the future?

Typical drivers of manufacturing costs of a product are the economies of scale and learning curve efficiencies that occur with repeat jobs. In particular, the latter is increasingly being replaced and made obsolete by automation. However, this does not yet mean production costs are independent of the number of units. The questions are, therefore: What should a production protocol ideally look like to realize batch size-independent production costs? What are the prerequisites for this? And can such a production landscape also produce sustainably at competitive unit costs?

Consistent digitization

Of course, the demand for batch size-independent production costs requires a whole range of conditions and measures. A central prerequisite for agile production is continuous digitization and connectivity. This begins with the parts to be manufactured and extends over the entire manufacturing process including the entire hardware (e.g. machine tools, tools, pallets, robots, etc.). The goal of continuous digitization is to dematerialize everything that can be dematerialized. The parts to be manufactured must therefore be available in digital form, as must the associated manufacturing process with its hardware components. It should not matter whether the production logistics of the parts are pallet based or with the help of workpiece handling.

Seamless communication

Further, all hardware and software components must be connected and able to communicate with each other throughout the entire manufacturing process, from the interface to order management to the end product. A central control and monitoring software are required as a kind of superordinate authority, which plans all orders and the necessary manufacturing processes, forecasts, controls, monitors and, if possible, visualizes their completion.

The trend: universal machines

Another important prerequisite for agile manufacturing is that all machines in the manufacturing process (e.g. machine tools, control, and measuring machines, etc.) can machine or inspect all parts. In other words, universal machines are becoming an important component, since the machine park must be able to produce parts even if they change over the production period. This is also reflected in the market trend that can be observed towards the purchase of more and more universal machines. In practice, this does not necessarily mean a machine park from one manufacturer, but it may still be unavoidable.

Scalability of the manufacturing system

Scalability is another important feature of an agile manufacturing system. The gradual expansion over time must not mean that previous investments in the machinery no longer fit in or no longer allow expansion at all. This gives the investment in the machine park more security.

Intelligent tool management

Finally, it is mandatory to have a sufficient number of tools, which are also available for all machines. Without intelligent tool management via powerful software, virtually nothing works. A highly efficient production process can only be achieved if all the necessary, operational tools can be accessed immediately and without interruption during the production process. The corresponding tool management must, therefore, ensure high tool availability with regard to all parts to be manufactured and thus be able to control the use of tools simultaneously with ongoing production and monitor their service lives.

Under these conditions, all parts to be manufactured can be manufactured at any time by optimal control of the manufacturing processes via a central, powerful software. It should not matter whether only one part, 10 parts or 100 parts have to be produced. Setup costs are in principle not available and therefore the manufacturing costs per piece are independent of batch size.

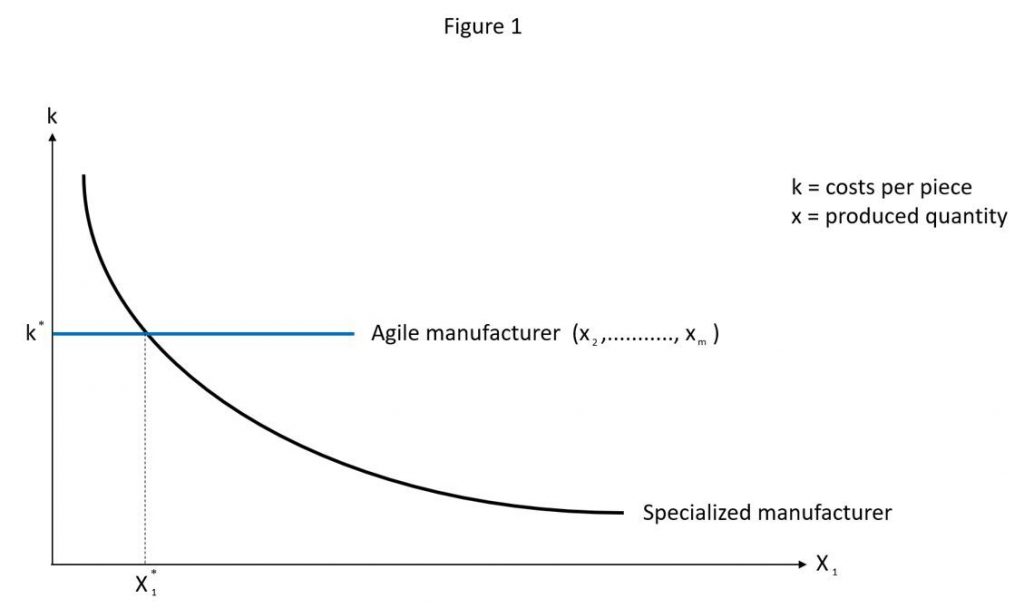

Scenario 1: Compared to a specialized manufacturer, a manufacturer with an agile manufacturing strategy incurs batch size independent manufacturing costs per unit. (see Figure 1)

Relativization of fixed costs

As promising as this statement may be for the machining processes of the future, it is not entirely true. Of course, fixed costs are also incurred at several points in this production landscape, which cause a quantity effect. On the one hand, these costs arise when setting up a new workpiece to be manufactured (e.g. digitizing the workpieces, running in the machines, etc.). These fixed costs, however, should generally not play a major role in reorders, even in small quantities.

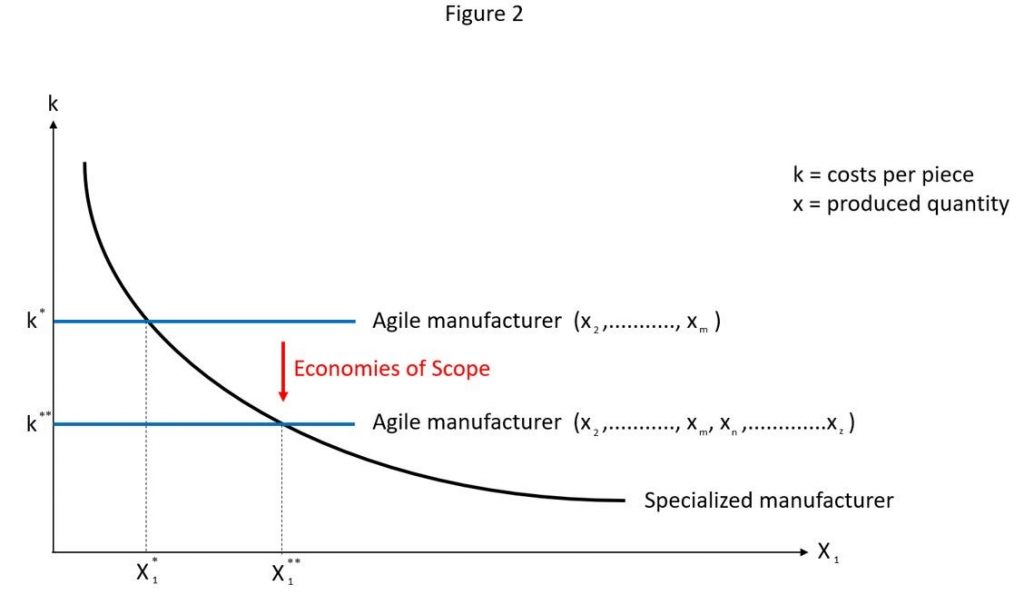

Economies of Scope

On the other hand, investment in the agile manufacturing system has an impact. So anyone who produces a small number of units in total will not incur any competitive unit costs with the investment, which is broken down to the individual unit to be produced. This will change, however, if you produce small batch sizes, but many of them for different workpieces. Then the economies of scope come into play if the manufacturer has a sufficiently large variety of parts to be produced. Because many different workpieces to be produced justify a correspondingly large investment in hardware and software. Of course, the production program must be designed in such a way that the workpieces to be machined are similar in their dimensions and do not exceed or fall short of certain limits. But this shouldn’t be a problem given the versatility of universal machines available today and the opposite variety of parts to be produced on the market. On the other hand, automation and the comprehensive software ensure that resources are optimally utilized.

Scenario 2: A manufacturer with an agile manufacturing system can reduce its manufacturing costs per piece over its entire manufacturing program as the variety of parts increases. (see Figure 2)

Competitive unit costs

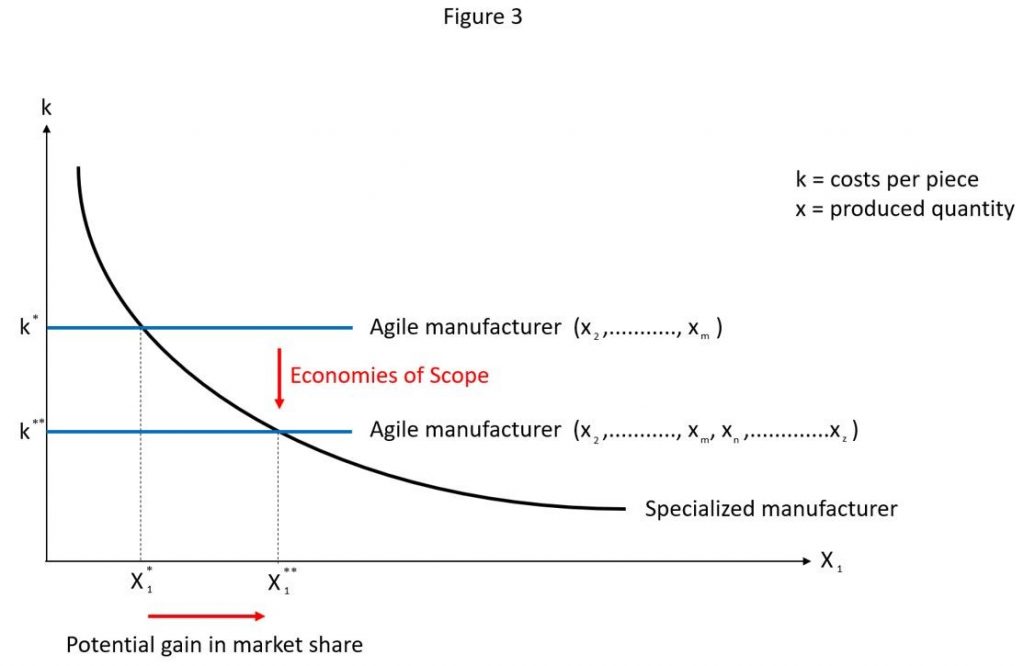

In this scenario, it is not unrealistic for a manufacturer with a large number of small batch sizes to be able to produce more cost-effectively and batch-independently with the same unit costs compared to a specialized manufacturer that produces larger quantities of a few parts. Digitization, networking, automation, scalability, and economies of scope, therefore, go hand in hand.

Scenario 3: Manufacturers with an agile production strategy gain market share from specialized manufacturers as the variety of parts increases. (see Figure 3)

The future is reality

The described prerequisites for an agile manufacturing system can already be realized today because the tools for a high-grade digitalization of production are already available. The connected hardware, the corresponding automation systems, and the software are also available. And there are already examples of practical implementation, as demonstrated by Norbert Kempf CNC-Technik GmbH in St. Ingbert (Saarland).

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product